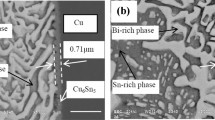

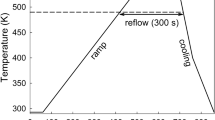

The 0.2Co + 0.1Ni dual additives were used to dope a Sn-3.5Ag solder matrix to modify the alloy microstructure and the solder joint on an organic solderability preservative (OSP) Cu pad. The refined microstructure of the Sn-3.5Ag-0.2Co-0.1Ni solder alloy or the reduced β-Sn size was attributed to the depressed undercooling achieved by the Co-Ni addition. After soldering on the OSP Cu pad, a large Ag3Sn plate was formed at the Sn-3.5Ag/OSP solder joint, whereas it was absent at the Sn-3.5Ag-0.2Co-0.1Ni/OSP solder joints. With isothermal aging at 150°C, large Ag3Sn plates formed at the Sn-3.5Ag/OSP solder joint were still observed. A coarsened and dispersed Ag3Sn phase was found in the solder joints with Co-Ni additions as well. Compared to Cu6Sn5, the (Co,Ni)Sn2 intermetallic compound showed much lower microhardness values. However, (Co,Ni)Sn2 hardness was comparable to that of the Ag3Sn phase. Pull strength testing of Sn-3.5Ag-0.2Co-0.1Ni/OSP revealed slightly lower values than for Sn-3.5Ag/OSP during aging. Such results are thought be due to the phase transformation of (Co,Ni)Sn2 to (Cu,Co,Ni)6Sn5.

Similar content being viewed by others

References

S.K. Kang, P. Lauro, and D.-Y. Shih et al., Mater. Trans. 45, 695 (2004)

K. Zeng, and K.N. Tu, Mater. Sci. Eng. R. 38, 55 (2002)

Z. Mei, J. Electron. Packaging. 117, 105 (1995)

S.-W. Chen, C.-C. Lin, and C.-M. Chen, Metall. Mater. Trans. A. 29, 1965 (1998)

K.W. Moon, W.J. Boettinger, U.R. Kitten, F.S. Biancaniello, and C.A. Handwerker, J. Electron. Mater. 29, 1122 (2000)

I. Ohnuma, M. Miyashita, K. Anzai, X.J. Liu, H. Ohtani, R. Kainuma, and K. Ishida, J. Electron. Mater. 29, 1137 (2000)

K.S. Kim, S.H. Huh, and K. Suganuma, Mater. Sci. Eng. A. 333, 106 (2002)

D.W. Henderson, T. Gosselin, A. Sarkhel, S.K. Kang, W.-K. Choi, D.-Y. Shih, C. Goldsmith, and K.J. Puttlitz, J. Mater. Res. 17, 2775 (2002)

S.K. Kang, D.-Y. Shih, D. Leonard, D.W. Henderson, T. Gosselin, S.-L. Cho, J. Yu, and W.K. Choi, JOM 56, 34 (2004)

A. Ohno, and T. Motegi, J. Japan. Inst. Metals. 37, 777 (1973)

L. Snugovsky, D.D. Perovic, and J.W. Rutter, Powder Metall. 48, 193 (2005)

Acknowledgement

Financial support from the Japan Society for the Promotion of Science (JSPS) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, F., Nishikawa, H. & Takemoto, T. Intermetallics Evolution in Sn-3.5Ag Based Lead-Free Solder Matrix on an OSP Cu Finish. J. Electron. Mater. 36, 1630–1634 (2007). https://doi.org/10.1007/s11664-007-0243-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-007-0243-0