Abstract

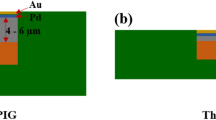

The Ni-based under-bump metallurgies (UBMs) are of interest because they have a slower reaction rate with Sn-rich solders compared to Cu-based UBMs. In this study, several UBM schemes using Ni as the diffusion barrier are investigated. Joints of Sn-58Bi/Au/electroless nickel (EN)/Cu/Al2O3 and Sn-58Bi/Au/electroplated nickel/Cu/Al2O3 were aged at 110°C and 130°C for 1–25 days to study the interfacial reaction and microstructural evolution. The Sn-Bi solder reacts with the Ni-based multimetallization and forms the ternary Sn-Ni-Bi intermetallic compound (IMC) during aging at 110°C. Compositions of ternary IMC were (78–80)at.%Sn-(12–16)at.%Ni-(5–8)at.%Bi in joints of Sn-58Bi/Au/Ni-5.5wt.%P/Cu, Sn-58Bi/Au/Ni-12wt.%P/Cu, and Sn-58Bi/Au/Ni/Cu. Elevated aging at 130°C accelerates the IMC growth rate and results in the formation of (Ni,Cu)3Sn4 and (Cu,Ni)6Sn5 adjacent to the ternary Sn-Ni-Bi IMC for the Sn-58Bi/Au/Ni-12wt.%P/Cu and Sn-58Bi/Au/Ni/Cu joints, respectively. The Cu content in the (Cu,Ni)6Sn5 IMC is six times that in (Ni,Cu)3Sn4. Electroplated Ni fails to prevent Cu diffusion toward the Ni/solder interface as compared to EN-based joints. Cracks are observed in the Sn-58Bi/Au/Ni-5.5wt.%P/Cu/Al2O3 joint aged at 130°C for 25 days. It is more favorable to employ Ni-12wt.%P for the Sn-58Bi/Au/EN/Cu joint. Electroless nickel, with the higher P content of 12 wt.%, is a more effective diffusion barrier during aging. In addition, P enrichment occurs near the interface of the EN/solder, and the degree of P enrichment is enhanced with aging time. The Au(Sn,Bi)4, with pyramidal and cubic shape, is observed in the Sn-58Bi/Au/Ni/Cu/Al2O3 joint.

Similar content being viewed by others

References

B.J. Freyman and R.C. Marrs, Electronic Manufacturing Technology Symp. (Piscataway, NJ: IEEE, 1993), pp. 41–45.

K.L. Lin and Y.C. Liu, Proc. Electronic Components and Technology Conf. (Piscataway, NJ: IEEE, 1999), pp. 607–612.

R.C. Marrs, Proc. 2nd Int. Conf. Exhibition on Multichip Modules (Bellingham, WA: ISHM and IEPS with SPIE, 1993), pp. 220–225.

J.W. Jang, D.R. Frear, T.Y. Lee, and K.N. Tu, J. Appl. Phys. 88, 6359 (2000).

D.R. Frear, F.M. Hosking, and P.T. Vianco, Proc. Materials Developments in Microelectronic Packaging Conf. (Materials Park, OH: ASM International, 1991), pp. 229–240.

C.Y. Lee and K.L. Lin, Jpn. J. Appl. Phys. 33, 4708 (1994).

T.A. Powers, T.J. Singler, and J.A. Clum, J. Electron. Mater. 23, 773 (1994).

R.B. Cinque and J.W. Morris, J. Electron. Mater. 23, 533 (1994).

H.D. Blair, T.Y. Pan, and J.M. Nicholson, Proc. Electronic Component and Technology Conf. (Piscataway, NJ: IEEE, 1998), pp. 259–267.

A.C.K. So and Y.C. Chan, Trans. Comp., Packag., Manuf. Technol. 19B, 661 (1996).

B.L. Young, J.G. Duh, and B.S. Chiou, J. Electron. Mater. 30, 543 (2001).

C.S. Huang, J.H. Yeh, B.L. Young, and J.G. Duh, J. Electron. Mater. 31, 1230 (2002).

B.L. Young and J.G. Duh, J. Electron. Mater. 30, 878 (2001).

T. Massalski, Binary Alloy Phase Diagram (Materials Park, OH: ASM International, 1986), p. 540.

H.W. Miao, J.G. Duh, and B.S. Chiou, J. Mater. Sci. 11, 609 (2000).

R.E. Reed-Hill and R. Abbaschian, Physical Metallurgy Principles (Boston, MA: PWS Publishing Company, 1994), p. 364.

J.I. Goldstein, Scanning Electron Microscopy and X-ray Microanalysis (New York: Plenum Press, 1981), p. 405.

R.E. Reed-Hill and R. Abbaschian, Physical Metallurgy Principles (Boston, MA: PWS Publishing Company, 1994), p. 278.

T.A. Powers, T.J. Singler, and J.A. Clum, J. Electron. Mater. 23, 773 (1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Young, BL., Duh, JG. & Jang, GY. Compound formation for electroplated Ni and electroless Ni in the under-bump metallurgy with Sn-58Bi solder during aging. J. Electron. Mater. 32, 1463–1473 (2003). https://doi.org/10.1007/s11664-003-0116-0

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-003-0116-0