Abstract

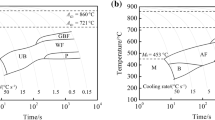

For some Si-killed steel grades, it is desirable to obtain calcium or manganese silico-aluminate inclusions with low-melting temperatures, which form a glassy phase at low temperatures and are easily elongated and reduced in size during hot rolling. However, these inclusions sometimes exhibit coarse crystallization changes during heat treatment before hot rolling, which affects the rheological properties of inclusions. In the present work, the composition, morphology, and size of inclusions in Si-killed spring steel by two types of bloom-heating processes were investigated. It was found that most oxide inclusions in the billet were glassy and had good rolling deformability when a 1523 K × 150 minutes bloom-heating process was adopted. However, when a heating process of 1373 K × 40 minutes was adopted, the oxide inclusions had a high proportion of crystallization, and most of them had poor rolling deformability. Due to the influence of different crystallization ratios and crystal sizes of inclusions, the maximum inclusion sizes of the corresponding wire rods were 20 and 35 μm, respectively. On the basis of these results, it was suggested that to improve the inclusion control of Si-killed spring steel, the heating temperature and time before blooming should be selected in the high-temperature region above the nose temperature of the inclusion TTT transformation curve.

Similar content being viewed by others

References

Y. Prawoto, M. Ikeda, S.K. Manville, and A. Nishikawa: Eng. Fail. Anal., 2008, vol. 15, pp. 1155–74.

T. Jinbo, T. Fujiwara, S. Suda, and N. Ibaraki: KOBELCO Technol. Rev., 2007, vol. 27, pp. 23–27.

Y.Q. Meng, Y.R. Zheng, and H.Q. Zhao: J. Iron Steel Res., 2015, vol. 27, pp. 1–6. (in Chinese).

S. Suda and N. Ibaraki: KOBELCO Technol. Rev., 2005, vol. 26, pp. 21–25.

Y. Murakami: JSME Int. J., 1989, vol. 32, pp. 167–80.

Y. Furuya, S. Matsuoka, and T. Abe: Metall. Mater. Trans. A, 2004, vol. 35, pp. 3737–44.

R.Z. Wang and J.L. Ru: China Surf. Eng., 2016, vol. 29, pp. 1–9. (in Chinese).

C. Bertrand, J. Molinero, S. Landa, R. Elvira, M. Wild, G. Barthold, P. Valentin, and H. Schifferl: Ironmak. Steelmak., 2003, vol. 30, pp. 165–69.

Y. Hu, W.Q. Chen, C.J. Wan, F.J. Wang, and H.B. Han: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 569–80.

A. Gilles, F. Michel, L. Fabrice, and S. Jean: Wire J. Int., 1998, vol. 31, pp. 84–89.

H.L. Yang, J.S. Ye, X.L. Wu, Y.S. Peng, Y. Fang, and X.B. Zhao: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 1435–44.

E.V.O. Lima, G.H. Sousa, J.G. Costa Neto, J.J. Mol Peixoto, and C.A. Silva: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2187–98.

C. Zhao, S.M. Jung, Y. Kashiwaya, H. Gaye, and H.G. Lee: ISIJ Int., 2008, vol. 48, pp. 747–54.

P. Rocabois, J.N. Pontoire, H. Gayes, J. Lehmann, and C. Gatellier: Revue De Metallurgie-CIT, 1997, vol. 94, pp. 1393–1400.

T. Shiraiwa, N. Fujino, and F. Matsuno Toshio: Sumitomo Met., 1974, vol. 11, pp. 85–100.

G.M. Faulring and S. Ramalingam: Metall. Trans. A, 1979, vol. 10, pp. 1781–88.

K.P. Wang, Y. Wang, J.M. Liao, J.F. Xu, M. Jiang, and X.H. Wang: Iron Steel, 2022, vol. 57, pp. 101–08. (in Chinese).

K. Yamada, Y. Hashimoto, T. Fujita, Y. Aoki, and H. Tada: Tetsu-to-Hagane, 1981, vol. 67, pp. 1338–44.

M. Jiang, J.C. Liu, K.L. Li, R.G. Wang, and X.H. Wang: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1950–54.

K.P. Wang, M. Jiang, X.H. Wang, Y. Wang, H.Q. Zhao, and Z.M. Cao: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2961–69.

H. Arai, K. Matsumoto, S. Shimasaki, and S. Taniguchi: ISIJ Int., 2009, vol. 49, pp. 965–74.

P. Rocabois, J.N. Pontoire, J. Lehmann, and H. Gaye: J. Non-Cryst. Solids, 2001, vol. 282, pp. 98–109.

P. Riboud, C. Gatellier, H. Gaye, J.N. Pontoire, and P. Rocabois: ISIJ Int., 1996, vol. 36, pp. S22–25.

Z.T. Li, N. Liu, W. Yang, and L.F. Zhang: J. Non-Cryst. Solids, 2022, vol. 579, p. 121367.

Y.Q. Meng, W. Wang, J.Y. Li, H.Q. Zhao, Z.F. Lu, and S.C. Qin: Steelmaking, 2021, vol. 37, pp. 58–61. (in Chinese).

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51974210), the Hubei Provincial Natural Science Foundation (No. 2019CFB697), and the State Key Laboratory of Refractories and Metallurgy, Wuhan University of Science and Technology.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meng, Y., Li, J., Wang, K. et al. Effect of the Bloom-Heating Process on the Inclusion Size of Si-Killed Spring Steel Wire Rod. Metall Mater Trans B 53, 2647–2656 (2022). https://doi.org/10.1007/s11663-022-02557-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02557-8