Abstract

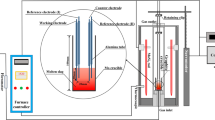

An electropulsing-assisted mold simulator (EPMS) technique was developed to investigate the effect of pulsed electric current on the initial solidification behavior of molten steel during the process of continuous casting. The results indicated that the variation of mold hot surface temperatures in the meniscus area decreased from 375.8 K to 394 K for the case without electropulsing treatment (EPT) to 363.5 K to 377.3 K for the one with EPT. The mold surface heat fluxes fluctuated around the baseline of 0.83 and 2.42 MW/m2 in the cases with and without EPT, respectively, which indicated that a higher thermal resistance between the initial shell and copper mold was introduced by employing the EPT. The crystal fraction of slag films increased from 69.8 to 77.9 pct, whereas the grain size of mold flux film decreased, when compared the case of EPT treatment with the benchmark one, which suggested that the pulsed electric current promotes the movement of molten clusters and particles, leading to the enhancement of mold flux crystallization and the improvement of thermal resistance. Moreover, the solidification structure of steel along the direction of solidification (from the mold to melt) includes a fine chilled grain layer close to the mold, a columnar dendrite layer in the middle, and equiaxed grains next to the melt core, in which a compacted microstructure with smaller secondary dendrite arm spacing was observed in the case of the EPT. The results demonstrate that the EPT could refine the as-cast solidification microstructure.

Similar content being viewed by others

References

E. Takeuchi and J. Brimacombe: Metall. Trans. B, 1984, vol. 15B, pp. 493–509.

J. Brimacombe and K. Sorimachi: Metall. Trans. B, 1977, vol. 8B, pp. 489–505.

S. Mazumdar and S. Ray: Sadhana, 2001, vol. 26, pp. 179–98.

J. Birat, M. Larrecq, J. Lamant, and J. Petegnief: Steelmaking Conf. Proc., ISS-AIME, Warrendale, PA, 1991, vol. 74, pp. 39–40.

K. Schmidt, F. Friedel, K. Imlau, W. Jager, and K. Muller: Steel Res. Int., 2003, vol. 74, pp. 659–66.

E. Takeuchi and J. Brimacombe: Metall. Trans. B, 1985, vol. 16B, pp. 605–25.

K. Schwerdtfeger and H. Sha: Metall. Mater. Trans. B, 2012, vol. 31B, pp. 813–26.

P. Ramirez-Lopez, K. Mills, P. Lee, and B. Santillana: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 109–122.

D. Bouchard, J. Nadeau, D. Simard, F. Hamel, B. Howes, and C. Paumelle: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 403–11.

A. Badri, T. Natarajan, C. Snyder, K. Powers, F. Mannion, and A. Cramb: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 355–71.

E. Ko and I. Sohn: 5th Int. Congr. Sci. Technol. Steelmak., Dresden, Germany, TU Bergakademie Freiberg, Germany, 2012.

M. Santillana: Ph.D. Dissertation, TU Delft University of Technology, Delft, Netherlands, 2013.

J. Savage and W. Pritchard: J. Iron Steel Inst. London, 1954, vol. 178, pp. 269–77.

K. Blazek, I. Saucedo, and H. Tsai: Steelmaking Conf. Proc., ISS-AIME, Warrendale, PA, 1988, vol. 71, pp. 411–21.

W. Wang, Z. Lou, and H. Zhang: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 1034–45.

P. Lyu, W. Wang, X. Long, K. Zhang, E. Gao, and R. Qin: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 78–88.

H. Zhang and W. Wang: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 779–93.

P. Lyu, W. Wang, and H. Zhang: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 247–59.

H. Zhang and W. Wang: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 920–31.

H. Zhang, W. Wang, F. Ma, and L. Zhou: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 2361–73.

B. Zi, K. Yao, W. Liu, J. Cui, and Q. Ba: Rare Metal Mater. Eng., 2003, vol. 32, pp. 9–12.

J. Barnak, A. Sprecher, and H. Conrad: Scripta Metall. Mater., 1995, vol. 32, pp. 879–84.

S. He, J. Wang, B. Sun, and X. Zhou: T. Nonferr. Met. Soc., 2005, vol. 12, pp. 275–78.

H. Sun, D. Lv, W. Li, and Y. Jiang: J. Harbin Univ. Commerce, 2011, vol. 27, pp. 733–40.

X. Liao, Q. Zhai, J. Luo, W. Chen, and Y. Gong: Acta Mater., 2007, vol. 55, pp. 3103–09.

D. Rabiger, Y. Zhang, V. Galindo, S. Franke, B. Willers, and S. Eckert: Acta Mater., 2014, vol. 79, pp. 327–38.

Y. Zhou, S. Xiao, and J. Guo: Mater. Lett., 2004, vol. 58, pp. 1948–51.

Z. Lu, C. Guo, P. Li, Z. Wang, Y. Chang, G. Tang, and F. Jiang: J. Alloys Compd., 2017, vol. 708, pp. 834–43.

S. Ahmed and E. Mckannan: Mater. Sci. Technol., 1994, vol. 10, pp. 941–46.

M. Nakada, Y. Shiohara, and M. Flemings: ISIJ Int., 1990, vol. 30, pp. 27–33.

Z. Zhao, J. Wang, and L. Liu: Mater. Manuf. Process., 2011, vol. 26, pp. 249–54.

Y. Jiang, G. Tang, C. Shek, J. Xie, Z. Xu, and Z. Zhang: J. Alloys Compd., 2012, vol. 536, pp. 94–105.

G. Li, L. Wang, Y. Liu, W. Zhang, X. Qiao, and Y. Wang: Rare Met. Mater. Eng., 2011, vol. 40, pp. 961–66.

H. Liu, Z. Zhao, and L. Ma: Foundry Technol., 2008, vol. 29, pp. 1354–58.

B. Ma, Y. Zhao, J. Ma, H. Guo, and Q. Yang: J. Alloys Compd., 2013, vol. 549, pp. 77–81.

R. Qin, A. Rahnama, W. Lu, X. Zhang, and B. Elliott-Bowman: Mater. Sci. Technol., 2014, vol. 30, pp. 1040–44.

W. Lu and R. Qin: Adv. Mater. Res., 2014, vol. 922, pp. 441–45.

H. Jeong, M. Kim, J. Park, C. Yim, J. Kim, O. Kwon, P. Madakashira, and H. Han: Mater. Sci. Eng. A, 2017, vol. 684, pp. 668–76.

S. Lin, X. Chu, W. Bao, J. Gao, and L. Ruan: Mater. Sci. Technol., 2014, vol. 31, pp. 1131–38.

Y. Zhou, J. Guo, M. Gao, and G. He: Mater. Lett., 2004, vol. 58, pp. 1732–36.

H. Wang, G. Song, and G. Tang: Mater. Sci. Eng. A, 2016, vol. 662, pp. 456–67.

H. Song, Z. Wang, X. He, and J. Duan: Sci. Rep., 2017, vol. 7, pp. 1–11.

Z. Xu, G. Tang, S. Tian, and J. He: Mater. Sci. Eng. A, 2006, vol. 424, pp. 300–06.

Y. Zhou, S. Xiao, and J. Guo: Mater. Lett., 2004, vol. 58, pp. 1948–51.

Z. Xu, G. Tang, F. Ding, S. Tian, and H. Tian: Appl. Phys. A, 2007, vol. 88, pp. 429–33.

D. Ben, H. Yang, Y. Ma, X. Shao, J. Pang, and Z. Zhang: Mater. Sci. Eng. A, 2018, vol. 725, pp. 28–32.

Y. Zhou, J. Guo, W. Zhang, and G. He: J. Mater. Res., 2002, vol. 17, pp. 3012–14.

Y. Zhu, T. Sandy, W.B. Lee, X. Liu, Y. Jiang, and G. Tang: J. Mater. Res., 2011, vol. 24, pp. 2661–69.

H. Zhang, W. Wang, and L. Zhou: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 2137–52.

X. Zhang and R. Qin: Sci. Rep., 2015, vol. 5, pp. 1–7.

S Riaz: Ironmak. Steelmak., 2013, vol. 39, pp. 409–13.

F. Ma, Y. Liu, W. Wang, and H. Zhang: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1902–11.

J. Park, G. Kim, J. Kim, S. Park, and I. Sohn: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 2582–94.

D. Yoon, J. Cho, and S. Kim: Met. Mater. Int., 2015, vol. 21, pp. 580–87.

J. Yang, Y. Cui, L. Wang, Y. Sasaki, J. Zhang, O. Ostrovski, and Y. Kashiwaya: Steel Res. Int., 2015, vol. 86, pp. 636–43.

J. Zeng, W. Chen, G. Wang, C. Cao, and Y. Gao: Metall. Res. Technol., 2015, vol. 112, pp. 403–10.

Acknowledgments

The financial support from the National Natural Science Foundation of China (Grant No. U1760202), Hunan Scientific Technology projects (Grant Nos. 2018RS3022 and 2018WK2051), and Fundamental Research Funds for the Central Universities of Central South University (Grant No. 2018zzts140) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 19, 2018.

Rights and permissions

About this article

Cite this article

Ying, G., Wang, W., Zhang, H. et al. Influence of Electropulsing Treatment on the Initial Solidification of Molten Steel During Continuous Casting. Metall Mater Trans B 50, 1608–1616 (2019). https://doi.org/10.1007/s11663-019-01601-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01601-4