Abstract

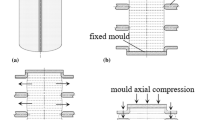

The chamfered mold with a typical corner shape (angle between the chamfered face and hot face is 45 deg) was applied to the mold simulator study in this paper, and the results were compared with the previous results from a well-developed right-angle mold simulator system. The results suggested that the designed chamfered structure would increase the thermal resistance and weaken the two-dimensional heat transfer around the mold corner, causing the homogeneity of the mold surface temperatures and heat fluxes. In addition, the chamfered structure can decrease the fluctuation of the steel level and the liquid slag flow around the meniscus at mold corner. The cooling intensities at different longitudinal sections of shell are close to each other due to the similar time-average solidification factors, which are 2.392 mm/s1/2 (section A-A: chamfered center), 2.372 mm/s1/2 (section B-B: 135 deg corner), and 2.380 mm/s1/2 (section D-D: face), respectively. For the same oscillation mark (OM), the heights of OM roots at different positions (profile L1 (face), profile L2 (135 deg corner), and profile L3 (chamfered center)) are very close to each other. The average value of height difference (HD) between two OMs roots for L1 and L2 is 0.22 mm, and for L2 and L3 is 0.38 mm. Finally, with the help of metallographic examination, the shapes of different hooks were also discussed.

Similar content being viewed by others

References

R.B. Mahapatra, J.K. Brimacombe, I.V. Samarasekara, N. Walker, E.A. Paterson, and J.D. Young: Metall. Mater. Trans. B, 1991, vol. 22B, pp. 861-74.

M.M. Wolf: Continuous Casting, vol. 9, Initial Solidification and Strand Surface Quality of Peritectic Steels, Iron and Steel Society, Warrendale, PA, 1997, pp. 1–111.

B.H. Nakato, M. Ozawa, K. Kinoshita, Y. Habu, and T. Emi: Trans. Iron Steel Inst. Jpn., 1984, vol. 24 (11), pp. 957–65.

K.D. Schmidt, F. Friedel, K.P. Imlau, W. Jäger, and K.T. Müller: Steel Res. Int., 2003, Vol. 74(11), pp. 659-666.

S. Harada, S. Tanaka, H. Misumi, S. Mizoguchi, and J. Horiguchi: Iron Steel Inst. Jpn. Int., 1990, vol. 30 (4), pp. 310–16.

S. Mazumdra and S.K. Ray: Sadhana, 2001, vol. 26 (1–2), pp. 179–98.

K. Schwerdfeger and H. Sha: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 813–26.

M.M. Wolf: Process. Technol., 1995, vol. 13, pp. 99–117.

M.M. Wolf: Steel Times Int., 1992, vol. 16 (2), p. 37.

H. Tomono: Ph.D. Dissertation: Swiss Federal Institute of Technology, Lausanne, Switzerland, 1979.

P. Ackermann: Ph.D. Dissertation: Swiss Federal Institute of Technology, Lausanne, Switzerland, 1983.

J. Sengupta, B. G. Thomas, H. J. Shin, G. G. Lee and S. H. Kim:Metall. Mater. Trans. A, 2006, vol. 37(5), pp. 1597-611.

P.E.R. Lopez, K.C. Mills, P.D. Lee, and B. Santillana: Metall. Mater. Trans. B, 2012, vol. 43B (1), pp. 109–22.

R.B. Mahapatra, J.K. Brimacombe, I.V. Samarasekara: Metall. Mater. Trans. B, 1991, vol. 22(B), pp. 875-88.

A. Matsushita, K. Isogami, M. Temma, T. Ninomiya, and K. Tsutsumi: Trans. Iron Steel Inst. Jpn., 1988, vol. 28 (7), pp. 531–34.

Badri, T.T. Natarajan, C.C. Snyder, K.D. Powers, F.J. Mannion, and A.W. Cramb: Metall. Mater. Trans. B, 2005, vol. 36B (3), pp. 355–71.

Badri, T.T. Natarajan, C.C. Snyder, K.D. Powers, F.J. Mannion, M. Byrne, and A.W. Cramb: Metall. Mater. Trans. B, 2005, vol. 36B (3), pp. 373–83.

J. Park, E. Ko, J. Choi, and I. Sohn: Met. Mater. Int., 2014, vol. 20 (6), pp. 1103–14.

E. Ko, J. Choi, J. Park, and I. Sohn: Met. Mater. Int., 2014, vol. 20 (1), pp. 141–51.

S.C. Moon: Ph.D. Dissertation, University of Wollongong, Wollongong, AUS, 2015.

H. Zhang, W. Wang, F. Ma, and L. Zhou: Metall. Mater. Trans. B, 2015, vol. 46B (5), pp. 2361–73.

H. Zhang and W. Wang: Metall. Mater. Trans. B, 2016, vol. 47B (2), pp. 920–31.

T. Araki and M. Ikeda: Can. Metall. Q., 1999, vol. 38 (5), pp. 295–300.

M. Suzuki, H. Mizukami, T. Kitagawa, K. Kawakami, S. Uchida, and Y. Komatsu: ISIJ Int., 2007, vol. 31 (3), pp. 254–61.

H. Shin, G. Lee, W. Choi, S. Kang, J. Park, S. Kim, and B. G. Tomas: AISTech 2004 Iron and Steel Technology Conf. Proc., Nashville, TN, 2004, pp. 1157–70.

C Genzano, J Madias, D Dalmaso, J Petroni, D Biurrun, and GD Gresia (2002) Iron Steelmaker 29:23-26.

I.G. Saucedo: Steelmaking Conf. Proc., ISS-AIME, Warrendale, PA, 1991, pp. 45-53.

J. K. Park, B. G. Thomas, and I.V. Samarasekera: Ironmak. Steelmak., 2002, vol. 29(5), pp. 359-75.

C Chow, I.V. Samarasekera, BN Walker, G Lockhart (2002) Ironmak. Steelmak., 29:61-69.

D Zhang, S Lei, S Zeng, H Shen (2014) ISIJ Int., 54:336–41.

P. Hu, H. Zhang, M. Wang, M. Zhu, X. Zhang, Y. Zhang, and Z. Zhang: Metall. Res. Technol., 2015, vol. 112 (1), pp. 1–10.

B. Patrick, S.G. Thornton. ECSC report, no. 7210.CA/821 (C1.3/85), Luxembourg, 1990.

H. Zhang, W. Wang, and L. Zhou: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 2137–52.

P. Lyu, W. Wang, and H. Zhang: Metall. Mater. Trans. B, 2017, vol. 46B (1), pp. 247–259.

C.E. Shannon: Proc. IRE, 1949, vol. 37, pp. 10–21.

A.V. Oppenheim, R.W. Schafer, and J.R. Buck: Discrete-Time Signal Processing, Prentice-Hall, Englewood Cliffs, 1989.

S.W. Smith: Digital Signal Processing: A Practical Guide for Engineers and Scientists, Newnes, Boston, 2003.

E Takeuchi, J.K. Brimacombe (1984) Metall. Mater. Trans. B, 15: 493-509.

T. Emi, H. Nakato, Y. Iida, K. Emota, R. Tachibana, T. Imai, and H. Bada: Steelmaking Conf. Proc., Iron and Steel Society, Warrendale, PA, 1978, vol. 61, pp. 350-61.

J. Sengupta, H.J. Shin, B.G. Thomas, and S.H. Kim: Acta Mater., 2006, vol. 54 (4), pp. 1165–73.

H. Tomono, P. Ackermann, W. Kurz, and W. Heinemann: Solidification Technology in the Foundry and Casthouse, The Metals Society, Coventry, England, 1983, pp. 524–31.

Acknowledgments

The financial support from the National Science Foundation of China (51661130154, U1760202) and Newton Advanced Fellowship (NA150320) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscrip submitted March 12, 2017.

Rights and permissions

About this article

Cite this article

Lyu, P., Wang, W., Long, X. et al. Study of the Effect of Mold Corner Shape on the Initial Solidification Behavior of Molten Steel Using Mold Simulator. Metall Mater Trans B 49, 78–88 (2018). https://doi.org/10.1007/s11663-017-1154-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1154-y