Abstract

In modern steelmaking, the decarburization of hot metal is converted into steel primarily in converter processes, such as the basic oxygen furnace. The objective of this work was to develop a new mathematical model for top blown steel converter, which accounts for the complex reaction equilibria in the impact zone, also known as the hot spot, as well as the associated mass and heat transport. An in-house computer code of the model has been developed in Matlab. The main assumption of the model is that all reactions take place in a specified reaction zone. The mass transfer between the reaction volume, bulk slag, and metal determine the reaction rates for the species. The thermodynamic equilibrium is calculated using the partitioning of Gibbs energy (PGE) method. The activity model for the liquid metal is the unified interaction parameter model and for the liquid slag the modified quasichemical model (MQM). The MQM was validated by calculating iso-activity lines for the liquid slag components. The PGE method together with the MQM was validated by calculating liquidus lines for solid components. The results were compared with measurements from literature. The full chemical reaction model was validated by comparing the metal and slag compositions to measurements from industrial scale converter. The predictions were found to be in good agreement with the measured values. Furthermore, the accuracy of the model was found to compare favorably with the models proposed in the literature. The real-time capability of the proposed model was confirmed in test calculations.

Similar content being viewed by others

Change history

30 October 2017

The reference for number 27 was incorrect. The correct reference is: 27. R. Sarkar, P. Gupta, S. Basu, and N.B. Ballal: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 961–76.

Abbreviations

- \( \rho \) :

-

Density (kg/m3)

- A :

-

Area (m2)

- V :

-

Volume (m3)

- \( m \) :

-

Mass (kg)

- \( \dot{m} \) :

-

Mass flux (kg/s)

- t :

-

Time (s)

- G :

-

Gibbs energy (J/mol)

- R :

-

Universal gas constant (J/(mol K))

- T :

-

Temperature (K)

- g :

-

Dimensionless Gibbs energy and gravitational acceleration (m/s2) in Chapter III.B

- x, X :

-

Mole fraction

- \( \mu \) :

-

Chemical potential of constituent (J/mol)

- n :

-

Molar amount (mol)

- b :

-

Mass constraint

- \( a_{ij} \) :

-

Stoichiometric matrix

- F :

-

Number of degrees of freedom

- \( C \) :

-

Number of components

- \( {{\Phi }} \) :

-

Total number of phases

- \( {{\Gamma }} \) :

-

Dimensionless chemical potential of component

- J :

-

Jacobian matrix

- D :

-

Dimensionless driving force

- \( \gamma \) :

-

Activity coefficient

- \( \varepsilon \) :

-

First-order interaction parameter

- \( {{\Delta }}g \) :

-

Gibbs energy of pair formation

- \( Z \) :

-

Coordination number

- Y :

-

Mass fraction and coordination equivalent fraction in Chapter 3.2

- \( {\text{q}} \) :

-

Gibbs energy coefficient of the pair fraction polynomial (J/mol)

- \( {{\omega }} \) :

-

Temperature independent part of the Gibbs energy coefficient (J/mol)

- \( {{\eta }} \) :

-

Temperature dependent part of the Gibbs energy coefficient [J/(mol K)]

- \( {\dot{\text{V}}} \) :

-

Volume flow rate (m 3 /s)

- \( H \) :

-

Enthalpy (J)

- S :

-

Entropy [J/(mol K)]

- \( \dot{H} \) :

-

Enthalpy flux (J/s)

- \( h \) :

-

Specific enthalpy (J/kg)

- \( c_{\text{p}} \) :

-

Heat capacity (J/(kg K))

- \( \varphi \) :

-

Enthalpy or mass source (J/s), (kg/s)

- \( \alpha \) :

-

Volume fraction

- \( h_{T} \) :

-

Heat transfer coefficient (W/(m2 K))

- \( h_{Y} \) :

-

Mass transfer coefficient (m/s)

- \( k \) :

-

Thermal conductivity (W/(m K))

- \( I \) :

-

Momentum (kg*m)/s2

- \( v \) :

-

Velocity (m/s)

- \( R_{\text{p}} \) :

-

Plume momentum ratio (dimensionless)

- g:

-

Gas

- m:

-

Metal

- s:

-

Slag

- mix:

-

Mixture

- i, j, l, k :

-

Generic indices

- A, B, C :

-

Components A, B, and C

- RZ:

-

Reaction zone

- Liq:

-

Liquidus

- T :

-

Temperature

- IF:

-

Interface

- ref:

-

Reference

- ex:

-

Excess Gibbs energy

- °:

-

Standrard state

- p:

-

Pure phase

- s:

-

Solution phase

- ν :

-

Iteration index

- n :

-

Time level

- e:

-

Equilibrium

References

H. Jalkanen and L. Holappa: Treatise on Process Metallurgy, vol. 3, S. Seetharaman, A. McLean, R. Guthrie and S. Sridhar, eds., Elsevier, Oxford, 2014, pp. 223–70.

N. Molloy: J. Iron Steel Inst., 1970, vol. 208, pp. 943–950.

F.-R. Block, A. Masui and G. Stolzenberg: Arch. Eisenhüttenwes., 1973, vol. 44, pp. 357–361.

W. Kleppe and F. Oeters: Arch. Eisenhüttenwes., 1976, vol. 47, pp. 271–275.

F. R. Cheslak, J. A. Nicholls and M. Sichel: J. Fluid Mech., 1969, vol. 36, pp. 55–63.

Subagyo, G. A. Brooks, K. S. Coley and G. A. Irons: ISIJ Int., 2003, vol. 43, pp. 983–989.

B.K. Rout, G. Brooks, M. Subagyo, A. Rhamdhani and Z. Li: Metall. Mater. Trans. B, 2016, vol. 47, pp. 3350–3361.

S. C. Koria and K. W. Lange: Metall. Trans. B, 1984, vol. 15, pp. 109–116.

S. C. Koria and K. W. Lange: Ironmaking Steelmaking, 1986, vol. 13, pp. 236–240.

R. C. Urquhart and W. G. Davenport: Can. Metall. Q., 1973, vol. 12, pp. 507–516.

E. Schürmann, G. Mahn, J. Schoop and W. Resch: Arch. Eisenhüttenwes., 1977, vol. 48, pp. 515-519.

T. Kootz, K. Behrens, H. Maas and P. Baumgarten: Stahl Eisen, 1965, vol. 85, pp. 857–865.

F. Oeters: Arch. Eisenhüttenwes., 1966, vol. 37, pp. 209–219.

K. W. Lange: Arch. Eisenhüttenwes., 1971, vol. 42, pp. 233–241.

K. Koch, W. Fix and P. Valentin: Arch. Eisenhüttenwes., 1976, vol. 47, pp. 659–663.

K. Koch, W. Fix and P. Valentin: Arch. Eisenhüttenwes., 1978, vol. 49, pp. 109-114.

S. Asai and I. Muchi: Trans. Iron Steel Inst. Jpn, 1970, vol. 10, pp. 250–263.

K.-C. Chou, U. B. Pal and R. G. Reddy: ISIJ Int., 1993, vol. 33, pp. 862–868.

S.-Y. Kitamura, H. Shibata and N. Maruoka, Steel Res. Int., 2008, vol. 79, pp. 586–590.

F. Pahlevani, S. Kitamura, H. Shibata and N. Maruoka: Steel Res. Int., 2010, vol. 81, pp. 617–622.

N. Dogan, G. A. Brooks and M. A. Rhamdhani: ISIJ Int., 2011, vol. 51, pp. 1086–1092.

N. Dogan, G. A. Brooks and M. A. Rhamdhani: ISIJ Int., 2011, vol. 51, pp. 1093–1101.

N. Dogan, G. A. Brooks and M. A. Rhamdhani: ISIJ Int., 2011, vol. 51, pp. 1102–1109.

A. K. Shukla, B. Deo, S. Millman, B. Snoeijer, A. Overbosch and A. Kapilashrami: Steel Res. Int., 2010, vol. 81, pp. 940–948.

Y. Lytvynyuk, J. Schenk, M. Hiebler and A. Sormann: Steel Res. Int., 2014, vol. 85, pp. 537–543.

Y. Lytvynyuk, J. Schenk, M. Hiebler and A. Sormann: Steel Res. Int., 2014, vol. 85, pp. 544–563.

S. Sarkar, P. Gupta, S. Basu and N. B. Ballal: Metall. Mater. Trans. B, 2015, vol. 46, pp. 961–976.

M. Han, Y. Li and Z. Cao, Neurocomputing, 2014, vol. 123, 415–423.

M. Han and C. Liu, Appl. Soft Comput., 2014, vol. 19, pp. 430–437.

H.-J. Odenthal, N. Uebber, J. Schlüter, M. Löpke, K. Morik and H. Blom: Stahl Eisen, 2014, vol. 134, pp. 62–67.

D. Laha, Y. Ren and P. N. Suganthan: Expert Syst. Appl., 2015, vol. 42, pp. 4687–4696.

A. Sorsa, J. Ruuska, J. Lilja and K. Leiviskä: IFAC-PapersOnLine, 2015, vol. 48, pp. 177–182.

T.W. Miller, J. Jimenez, A. Sharan, and D.A. Goldstein: The Making, Shaping and Treatment of Steels: Steelmaking and Refining, vol. 2, R.J. Fruehan, ed., The AISE Steel Foundation, Pittsburgh, 1998, pp. 475–524.

C. Cicutti, M. Valdez, T. Pérez, J. Petroni, A Gómez, R. Donayo, and L. Ferro: Proceedings of the Sixth International Conference on Molten Slags, Fluxes and Salts, Stockholm-Helsinki, 2000.

C. Cicutti, M. Valzed, T. Pérez, R. Donayo and J. Petroni: Latin Am. Appl. Res., 2002, vol. 32, pp. 237–240.

H. Jalkanen: Advanced Processing of Metals and Materials (Sohn International Symposium), Thermo and Physicochemical Principles: Iron and Steel Making, vol. 2, F. Kongoli and R. G. Reddy, eds., 2006, pp. 541–54.

M. Järvinen, V.-V. Visuri, E.-P. Heikkinen, A. Kärnä, P. Sulasalmi, C. De Blasio and T. Fabritius: ISIJ Int., 2016, vol. 56, pp. 1543–1552.

M. Ersson, L. Höglund, A. Tilliander, L. Jonsson and P. Jönsson: ISIJ Int., 2008, vol. 48, pp. 147–153.

M. Ek, Q. F. Shu, J. van Boggelen and D. Sichen: Ironmaking Steelmaking, 2012, vol. 39, pp. 77–84.

A. Kruskopf: Metall. Mater. Trans. B, 2015, vol. 46, pp. 1195-1206.

A. Kruskopf and S. Louhenkilpi: Proceedings of the METEC & 2nd ESTAD, Düsseldorf, Germany, 2015, p. 165.

A. Kruskopf: Metall. Mater. Trans. B, 2017, vol. 48, pp. 619–631.

M.H.A. Piro, Doctoral thesis, Royal Military College of Canada, 2011.

M. H. A Piro, S. Simunovic, T. M. Besmann, B.J. Lewis and W.T. Thompson, Comput. Mater. Sci., 2013, vol. 67, pp. 266–272.

M. H. A. Piro and S. Simunovic, CALPHAD, 2012, vol. 39, pp. 104–110.

A.D. Pelton and C. W. Bale, Metall. Mater. Trans. A, 1985, vol. 17, pp. 1211–1215.

G.K. Sigworth and J.F. Elliot, Metal Sci., 1973, vol. 8, pp. 298–310.

J. Miettinen, IAD—Thermodynamic Database for Iron-based alloys, Casim Consulting Oy, Espoo, 2017.

A. D. Pelton and M. Blander, Metall. Trans. B., 1986, vol. 17, pp. 805–815.

C. R. Swaminathan and V. R. Voller: Int. J. Num. Meth. Heat Fluid Flow, 1993, vol. 3, pp. 233–244.

J. R. Taylor and A. T. Dinsdale, CAPHAD, 1990, vol. 14, pp. 71–88

HSC Chemistry 8, version 8.1.0, Outotec Technologies, 1974–2015.

M. Timucin and A.E. Morris, Metall. Trans., 1970, vol. 1, pp. 3193–3201.

Slag Atlas, 1981, Verlag Stahleisen M.B.H., Düsseldorf, Germany, p. 68.

P. V. Riboud and M. Olette: Proceedings of the 7th International Conference on Vacuum Metallurgy, 1982, pp. 879–889, Iron and Steel Institute of Japan, Tokyo, Japan.

S. Paul and D.N. Ghosh, Metall. Mater. Trans. B, 2007, vol. 17B, pp. 461-469.

M. Hirasawa, K. Mori, M. Sano, A. Hatanaka, Y. Shimatani and Y. Okazaki, Trans. Iron Steel Inst. Jpn, 1987, vol. 27, pp. 277–282.

A. Chatterjee, N.-O. Lindfors and J.Å. Wester, Ironmaking Steelmaking, 1976, vol. 3, pp. 21–32.

K. Krishnapisharody and G.A Irons, Metall. Mater. Trans. B, 2013, vol. 44, pp. 1486–1498.

A. Kärnä, M. P. Järvinen and F. Fabritius, Steel Res. Int., 2013, vol. 86, pp. 1370–1378.

S. Ban-Ya, ISIJ Int., 1993, vol. 33, pp. 2–11.

Acknowledgments

This work was partly funded by the Finnish Funding Agency for Technology and Innovation (TEKES). The research was carried out within the framework of the DIMECC SIMP research program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 28, 2017.

A correction to this article is available online at https://doi.org/10.1007/s11663-017-1114-6.

Appendix A: Initial Values for Pair Fractions

Appendix A: Initial Values for Pair Fractions

Before starting the algorithm for the solution of the pair fractions, a reasonably good initial guess should be generated. This can be done by inserting Eq. [37] into Eq. [36]. After reorganizing, this produces three equations

where \( K_{AB} = { \exp }\left( {\frac{{{{\Delta }}g_{AB} }}{RT}} \right) \), etc. These equations are only functions of (X AB , X AC , X BC ). By subtracting the second row equation from the first row equation, subtracting the third row equation from the first row equation and subtracting the second row equation from the third row equation again three equations are obtained:

The advantage of this manipulation is that now each equation is only dependent on two unknown pair fractions. Also in Eq. [A2] there are no terms where two pair fractions are multiplying each other like in Eq. [A1]. By applying the solution of second degree polynomial equation to the first row equation, we get

where the coefficients are the terms multiplying the pair fractions in Eq. [A2]. So that X AB could have any real solutions the determinant should be either zero or positive:

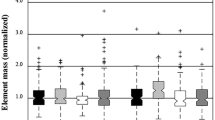

Using Eq. [A4] limits can be acquired for pair fraction X AC . In Figure 10, all possible parabolas are presented, which give limiting values for the pair fraction and have positive values for Eq. [A4] between X = [0, 1]. If product A AB A AC is negative, the parabola is opening down (Figure 10(a) through (c)). If the product is positive, the parabola is opening up (Figure 10(d) through (f)). For clarification, there are more possibilities for parabolas which give positive values when X = [0, 1], but these will not give new limits that are between [0, 1]. It is now assumed that Eq. [A4] has two solutions X 1 and X 2 as well as X 1 < X 2. If the parabola is opening down, the limiting values for X AC must be between the two solutions.

All possible parabolas from (a) to (f) for Eq. [A4] that can give limiting values for pair fraction

Since fractions can have values only between zero and one, the new limiting values for X AC can be calculated as follows:

where L AC is the lower limit and U AC is the upper limit. The upward opening parabola can give two ranges for limits that are between [0, 1]. This happens when 0 ≤ X 1, X 2 ≤ 1. The corresponding situation is in Figure 10(d). Then the first limits are

and the second limits are

The correct solution has to be between the first lower and upper limits or the second lower and upper limits. Using Eq. [A2] similarly as above limits can be acquired for the three pair fractions (X AB , X AC , X BC ). Additional improvements in the initial guesses can be achieved by inserting the limiting values for X AC in Eq. [A3] and studying whether the solutions for X AB are even more limiting than the previous limits. This second step was noticed to usually decrease the limits from previous values. Finally, the initial guesses are calculated as averages of the lower and upper limits:

Initial values for the three other pair fractions can now be calculated from Eq. [37].

Rights and permissions

About this article

Cite this article

Kruskopf, A., Visuri, VV. A Gibbs Energy Minimization Approach for Modeling of Chemical Reactions in a Basic Oxygen Furnace. Metall Mater Trans B 48, 3281–3300 (2017). https://doi.org/10.1007/s11663-017-1074-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1074-x