Abstract

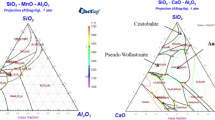

The evolution of oxide inclusions in Si-Mn killed steels refined by slags of different basicity during a four-pass industrial hot-rolling process was investigated using an automated microscopy system. High-basicity refining slag induced the formation of CaO- and Al2O3-containing inclusions, while refining slag with 0.8 basicity induced dominant inclusions of SiO2 and MnO-SiO2. CaO-SiO2-Al2O3 inclusions mainly formed endogenously during solidification and cooling of Ca-containing steels, where Ca originated from slag-steel reactions. However, the larger-sized higher-CaO inclusions originated from slag entrainment. Different inclusions presented different hot-rolling behaviors. The inclusion composition changed by deformation and new phase formation. The dominant oxide types were unchanged under refinement by low-basicity slag; however, they changed under refinement with high-basicity slag. The deformation index of inclusions decreased with increasing accumulated reduction (AR) of the steel. The difference in deformation index between different inclusion types was the largest in the first rolling stage and decreased in subsequent stages. SiO2-CaO and SiO2-MnO-CaO inclusions had larger deformation indices during hot rolling but smaller indices in the last two stages. High-basicity slag increased inclusion complexity; from the perspective of cold-drawing performance, low-basicity refining slag is better for the industrial production of tire-cord steels.

Similar content being viewed by others

Notes

LECO is a trademark of LECO Corporation, St. Joseph, MI.

References

K. Iemura, H. Ichihashi, A. Kawami, and M. Mizutani: Proc. 3rd Int. Conf. on Clean Steel, Institute of Metals, London, 1986, pp. 160–67.

Y. Shinsho, T. Nozaki, and K. Sorimachi: Wire J. Int., 1988, vol. 21, pp. 145–53.

S. Maeda, T. Soejima, and T. Saito: 72nd Steelmaking Conf. Proc., Iron & Steel Society, Chicago, IL, 1989, pp. 379–85.

H. Ohta and H. Suito: Metall. Mater. Trans. B, 1996, vol. 27B, pp. 263–70.

H. Suito and R. Inoue: ISIJ Int., 1996, vol. 36, pp. 528–36.

D.-H. Woo, Y.-B. Kang, and H.-G. Lee: Metall. Mater. Trans. B, 2002, vol. 33B, pp. 915–20.

Y.-B. Kang and H.-G. Lee: ISIJ Int., 2004, vol. 44, pp. 1006–15.

S.-H. Chen, M. Jiang, X.-F. He, and X.-H. Wang: Int. J. Miner. Metall. Mater., 2012, vol. 19, pp. 490–98.

J.S. Park and J.H. Park: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 953–60.

P. Gilormini and F. Montheillet: J. Mech. Phys. Solids, 1986, vol. 34, pp. 97–123.

R.D. Thomson and J.W. Hancock: Mechanical Behaviour of Materials—Proc. 4th Int. Conf., Elsevier, Amsterdam, Netherlands, 1984, pp. 733–37.

N. Nagayama, T. Abe, and S. Nagaki: Comput. Mechan., 1989, vol. 4, pp. 433–41.

M. Pietrzyk, J. Kusiak, H. Kusiak, and F. Grosman: Steel Res., 1991, vol. 62, pp. 507–11.

A.A. Milenin: Russ. Metall., 1995, vol. 16, pp. 97–103.

U. Ståhlberg: J. Mechan. Work. Technol., 1979, vol. 3, pp. 185–92.

C. Luo and U. Ståhlberg: Scand. J. Metall., 2002, vol. 31, pp. 184–90.

C. Luo and U. Ståhlberg: J. Mater. Process. Technol., 2001, vol. 114, pp. 87–97.

E. Ervasti and U. Ståhlberg: J. Mater. Process. Technol., 2005, vol. 170, pp. 142–50.

H.-L. Yu, H.-Y. Bi, X.-H. Liu, L.-Q. Chen, and N.-N. Dong: J. Mater. Process. Technol., 2009, vol. 209, pp. 4274–80.

F. Pickering and A. Met: J. Iron Steel Inst., 1958, vol. 189, pp. 148–59.

T. Malkiewicz and S. Rudnik: J. Iron Steel Inst., 1963, vol. 201, pp. 33–38.

S. Rudnik: J. Iron Steel Inst., 1966, vol. 204, pp. 374–76.

P.J.H. Maunder and J.A. Charles: J. Iron Steel Inst., 1968, vol. 206, pp. 705–15.

J. Charles and I. Uchiyama: J. Iron Steel Inst., 1969, vol. 207, pp. 979–83.

T.J. Baker and J.A. Charles: J. Iron Steel Inst., 1972, vol. 210, pp. 680–90.

P.E. Waudby: Steel Times Annu. Rev., 1972, vol. 200, pp. 147–52.

S. Ekerot: Scand. J. Metall., 1974, vol. 3, pp. 21–27.

K.B. Gove and J.A. Charles: Met. Technol., 1974, vol. 1, pp. 425–31.

B.-I. Klevebring: Scand. J. Metall., 1974, vol. 3, pp. 102–04.

T.J. Baker, K.B. Gave, and J.A. Charles: Met. Technol., 1976, vol. 3, pp. 183–93.

Y. Murty, T. Kattamis, R. Mehrabian, and M. Flemings: Metall. Trans. A, 1977, vol. 8A, pp. 1275–82.

S. Ramalingam, K. Basu, and S. Malkin: Mater. Sci. Eng., 1977, vol. 29, pp. 117–21.

A. Segal and J.A. Charles: Met. Technol., 1977, vol. 4, pp. 177–82.

F. Pickering and S. Robinson: Inst. Metall. Inclus., 1979, vol. 3, pp. 127–56.

F. Vodopivec and M. Gabrovšek: Met. Technol., 1980, vol. 7, pp. 186–91.

B. Gerard, R. Paul, and U. Georges: Rev. Metall., 1981, vol. 78, pp. 421–33.

G.I. Belchenko and S.I. Gubenko: Russ. Metall., 1983, vol. 4, pp. 66–69.

R. Maiti and E.B. Hawbolt: J. Mater. Energy Syst., 1985, vol. 6, pp. 251–62.

P. Rocabois, J.N. Pontoire, H. Gaye, J. Lehmann, and C. Gatellier: Rev. Metall., 1997, vol. 94, pp. 1393–1400.

M. Gagne and E. Thibault: CIM Bull., 1998, vol. 91, pp. 98–103.

S. Kimura, I. Hoshikawa, N. Ibaraki, S. Hattori, and T. Choda: Tetsu-to-Hagané, 2002, vol. 88, pp. 755–62.

K.-I. Yamamoto, H. Yamamura, and Y. Suwa: ISIJ Int., 2011, vol. 51, pp. 1987–94.

G. Xu, Z. Jiang, and Y. Li: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 2411–20.

K. Wang, M. Jiang, X. Wang, Y. Wang, H. Zhao, and Z. Cao: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 2198–2207.

K. Wang, M. Jiang, X. Wang, Y. Wang, H. Zhao, and Z. Cao: Metall. Mater, Trans, B, 2016, vol. 47, pp. 282–90.

Acknowledgments

The authors are grateful for the support from the National Science Foundation of China (Grant Nos. 51274034, 51334002, 51404019, 51604023, and 51504020), the Beijing Key Laboratory of Green Recycling and Extraction of Metals (GREM), the Laboratory of Green Process Metallurgy and Modeling (GPM2), and the High Quality Steel Consortium (HQSC) at the School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 16, 2016.

Rights and permissions

About this article

Cite this article

Yang, W., Guo, C., Zhang, L. et al. Evolution of Oxide Inclusions in Si-Mn Killed Steels During Hot-Rolling Process. Metall Mater Trans B 48, 2717–2730 (2017). https://doi.org/10.1007/s11663-017-1025-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-1025-6