Abstract

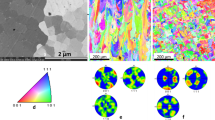

A high \(\gamma ^{\prime }\) volume fraction CoNi-base superalloy with roughly equal amounts of cobalt and nickel was successfully processed through selective laser melting. The as-printed alloy has a fine cellular structure with segregation of tantalum and significant built-in misorientation within the columnar grain structure. The microstructure evolution after various heat treatments was studied by electron backscatter diffraction and scanning electron microscopy. Super-solvus solution heat treatment promotes complete recrystallization of the microstructure which degrades elevated temperature tensile ductility. Post-processing involving sub-solvus hot isostatic pressing, solution heat treatment, and aging produces a bimodal \(\gamma ^{\prime }\) distribution while retaining a grain structure similar to the as-printed alloy. The evolution of the precipitate structure was strongly influenced by the cellular structure of the as-printed material. Peak hardness was reached after 2 hours of aging at 950 \(^{\circ }\hbox {C}\). Increasing the carbon content of the alloy promotes the formation of additional carbides on the grain boundaries. Room temperature and intermediate temperature (760 \(^{\circ }\hbox {C}\)) tensile testing measured parallel and perpendicular to the build direction revealed that the new heat treatments and carbon additions to the alloy resulted in improved yield strength, ultimate tensile strength, and ductility.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Notes

Inconel® is a registered trademark of Huntington Alloys Corporation.

CMSX-4® & CM 247 LC® are registered trademarks of Cannon-Muskegon Corporation.

SLM 125® is a registered trademark of SLM Solutions Group AG Stock Corporation.

Instron® & Vibromet® are registered trademarks of Illinois Tool Works Inc. Corporation.

Keyence® is a registered trademark of Keyence Corporation.

Thermo Fisher Scientific® is a registered trademark of Thermo Fisher Scientific Inc. Corporation.

FEI\(^{\mathrm{TM}}\) & Versa\(^{\mathrm{TM}}\) are trademarks of Thermo Fisher Scientific Inc. Corporation.

OIM Analysis\(^{\mathrm{TM}}\) is a trademark of AMETEK Inc.

FEI\(^{\mathrm{TM}}\), Dualbeam\(^{\mathrm{TM}}\), and Talos\(^{\mathrm{TM}}\) are trademarks of Thermo Fisher Scientific Inc. Corporation

Hastelloy® is a registered trademark of Haynes International Inc. Corporation.

References

W. Frazier: J. Mater. Eng. Perform., 2014, vol. 23, pp. 1917–28.

Y. Zhang, L. Wu, X. Guo, S. Kane, Y. Deng, Y. Jung, J. Lee, and J. Zhang: J. Mater. Eng. Perform., 2018, vol. 27, pp. 1–13.

T.M. Pollock, A. Clarke, and S. Babu: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 6000–19.

B. Song, X. Zhao, S. Li, C. Han, Q. Wei, S. Wen, J. Liu, and Y. Shi: Mech. Eng., 2015, vol. 10, pp. 111–25.

C. Yap, C. Chua, Z. Dong, Z. Liu, D. Zhang, L. Loh, and S. Sing: Appl. Phys. Rev., 2015, vol. 2, p. 041101.

X. Zhang, C.J. Yocom, B. Mao, and Y. Liao: J. Laser Appl., 2019, vol. 31, p. 031201.

H. Jia, H. Sun, H. Wang, Y. Wu, and H. Wang: Int. J. Adv. Manuf. Technol., 2021, vol. 113, pp. 2413–35.

E. Liverani, S. Toschi, L. Ceschini, and A. Fortunato: J. Mater. Process. Technol., 2017, vol. 249, pp. 255–63.

Y. Wang, T. Voisin, J. McKeown, J. Ye, N. Calta, Z. Li, Z. Zeng, Y. Zhang, W. Chen, T. Roehling, R. Ott, M. Santala, P. Depond, M. Matthews, A. Hamza, and T. Zhu: Nat. Mater., 2018, vol. 17, pp. 63–70.

A. Röttger, J. Boes, W. Theisen, M. Thiele, C. Esen, A. Edelmann, and R. Hellmann: Int. J. Adv. Manuf. Technol., 2020, vol. 108, pp. 769–83.

M. Simonelli, Y.Y. Tse, and C. Tuck: J. Phys., 2012, vol. 371, p. 012084.

H. Rafi, N. Karthik, H. Gong, T. Starr, and B. Stucker: J. Mater. Eng. Perform., 2013, vol. 22, pp. 3872–83.

P. Kumar, O. Prakash, and U. Ramamurty: Acta Mater., 2018, vol. 154, pp. 246–60.

E. Brandl, U. Heckenberger, V. Holzinger, and D. Buchbinder: Mater. Des., 2012, vol. 34, pp. 159–69.

W. Li, S. Li, J. Liu, A. Zhang, Y. Zhou, Q. Wei, C. Yan, and Y. Shi: Mater. Sci. Eng. A, 2016, vol. 663, pp. 116–25.

F. Trevisan, F. Calignano, M. Lorusso, J. Pakkanen, A. Aversa, E.P. Ambrosio, M. Lombardi, P. Fino, and D. Manfredi: Materials, 2017, vol. 10, p. 76.

J. Zhang, B. Song, Q. Wei, D. Bourell, and Y. Shi: J. Mater. Sci. Technol., 2019, vol. 35, pp. 270–84.

S. Li, Q. Wei, Y. Shi, C.K. Chua, Z. Zhu, and D. Zhang: J. Mater. Sci. Technol., 2015, vol. 31, pp. 946–52.

M. Leary, M. Mazur, H. Williams, E. Yang, A. Alghamdi, B. Lozanovski, X. Zhang, D. Shidid, L. Farahbod-Sternahl, G. Witt, I. Kelbassa, P. Choong, M. Qian, and M. Brandt: Mater. Des., 2018, vol. 157, pp. 179–99.

I. Koutiri, E. Pessard, P. Peyre, O. Amlou, and T. De Terris: J. Mater. Process. Technol., 2018, vol. 255, pp. 536–46.

Z. Wang, K. Guan, M. Gao, X. Li, X. Chen, and X. Zeng: J. Alloy Compd., 2012, vol. 513, pp. 518–23.

J. Strößner, M. Terock, and U. Glatzel: Adv. Eng. Mater., 2015, vol. 17, pp. 1099–1105.

T. Trosch, J. Strößner, R. Völkl, and U. Glatzel: Mater. Lett., 2016, vol. 164, pp. 428–31.

M.D. Sangid, T.A. Book, D. Naragani, J. Rotella, P. Ravi, A. Finch, P. Kenesei, J.S. Park, H. Sharma, J. Almer, and X. Xiao: Addit. Manuf., 2018, vol. 22, pp. 479–96.

R. Darolia: Int. Mater. Rev., 2019, vol. 64, pp. 355–80.

S. Babu, N. Raghavan, J. Raplee, S. Foster, C. Frederick, M. Haines, R. Dinwiddie, M. Kirka, A. Plotkowski, Y. Lee and R. Dehoff: Metall. Mater. Trans. A, 2018. vol. 49A, pp. 3764–80.

L.N. Carter, M.M. Attallah, and R.C. Reed: Laser powder bed fabrication of nickel-base superalloys: influence of parameters; Characterisation, quantification and mitigation of cracking, in Superalloys 2012. E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella, and J. Telesman, eds., TMS, Warrendale, 2012, pp. 577–86.

L.N. Carter, C. Martin, P.J. Withers, and M.M. Attallah: J. Alloy Compds., 2014, vol. 615, pp. 338–47.

S. Kou: Acta Mater., 2015, vol. 88, pp. 366–74.

S. Kou: Weld. J., 2015, vol. 94, pp. 374–88.

W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff, and S.S. Babu: Int. Mater. Rev., 2016, vol. 61, pp. 315–60.

S. Catchpole-Smith, N. Aboulkhair, L. Parry, C. Tuck, I.A. Ashcroft, and A. Clare: Addit. Manuf., 2017, vol. 15, pp. 113–22.

P. Kontis, E. Chauvet, Z. Peng, J. He, A. da Silva, D. Raabe, C. Tassin, J. Blandin, S. Abed, R. Dendievel, B. Gault, and G. Martin: Acta Mater., 2019, vol. 177, pp. 209–21.

H. Peng, Y. Shi, S. Gong, H. Guo, and B. Chen: Mater. Des., 2018, vol. 159, pp. 155–69.

A. Németh, D. Crudden, D. Collins, D. Armstrong, and R. Reed: Novel techniques to assess environmentally-assisted cracking in a Nickel-based superalloy. in Superalloys2016: Proceedings of the 13th International Symposium on Superalloys. M. Hardy, E. Huron, U. Glatzel, B. Griffin, B. Lewis, C. Rae, V. Seetharaman, and S. Tin, eds., TMS, Warrendale, PA, 2016, pp. 801–10.

A. Németh, D. Crudden, D. Armstrong, D. Collins, K. Li, A. Wilkinson, C. Grovenor, and R. Reed: Acta Mater., 2017, vol. 126, 361–71.

L.Z. He, Q. Zheng, X.F. Sun, G.C. Hou, H.R. Guan, and Z.Q. Hu: Mater. Sci. Eng. A, 2004, vol. 380, pp. 340–48.

L. Zheng, G. Schmitz, Y. Meng, R. Chellali, and R. Schlesiger: Crit. Rev. Solid State Mater. Sci., 2012, vol. 37, pp. 181–214.

H.J. Chung, J.Y. Huh, and W.S. Jung: Mater. Charact., 2018, vol. 140, pp. 9–14.

J. Kangazian, M. Shamanian, A. Kermanpur, E. Foroozmehr, and M. Badrossamay: Mater. Sci. Eng. A, 2021, vol. 823, p. 141742.

A. Sengupta, S. Putatunda, L. Bartosiewicz, J. Hangas, M. Peputapeck, and E. Alberts: J. Mater. Eng. Perform., 1994, vol. 3, pp. 73–81.

S. Griffiths, H. Ghasemi-Tabasi, A. De Luca, J. Pado, S. Joglekar, J. Jhabvala, R. Logé, and C. Leinenbach: Mater. Charact., 2021, vol. 171, p. 110815.

N. Li, S. Huang, G. Zhang, R. Qin, W. Liu, H. Xiong, G. Shi, and J. Blackburn: J. Mater. Sci. Technol., 2019, vol. 35, 242–69.

S.P. Murray, K.M. Pusch, A.T. Polonsky, C.J. Torbet, G.G.E. Seward, P. Nandwana, M.M. Kirka, R.R. Dehoff, N. Zhou, S.A.J. Forsik, W. Slye, and T.M. Pollock: Microstructure and tensile properties of a CoNi-based superalloy fabricated by selective electron beam melting. in Superalloys 2020. S. Tin, M. Hardy, J. Clews, J. Cormier, Q. Feng, J. Marcin, C. O’Brien, and A. Suzuki, eds., Springer, Berlin, 2020, pp. 880–90.

S. Murray, K. Pusch, A. Polonsky, C. Torbet, G. Seward, N. Zhou, S. Forsik, P. Nandwana, M. Kirka, R. Dehoff, W. Slye, and T. Pollock: Nat. Commun., 2020, vol. 11, p. 4975.

J. Koßmann, C. Zenk, I. Lopez-Galilea, S. Neumeier, A. Kostka, S. Huth, W. Theisen, M. Göken, R. Drautz, and T. Hammerschmidt: J. Mater. Sci., 2015, vol. 50, pp. 6329–38.

C. Stewart, S. Murray, A. Suzuki, T. Pollock, and C. Levi: Mater. Des., 2020, vol. 189, p. 108445.

N. Volz, C. Zenk, T. Halvaci, K. Matuszewska, S. Neumeier, and M. Göken: Castability and Recrystallization Behavior of γ’-Strengthened Co-Base Superalloys, Springer, Berlin, 2020.

M. Tsunekane, A. Suzuki, and T. Pollock: Intermetallics, 2011, vol. 19, pp. 636–43.

I. Lopez-Galilea, B. Ruttert, J. He, T. Hammerschmidt, R. Drautz, B. Gault, and W. Theisen: Addit. Manuf., 2019, vol. 30, p. 100874.

H. Wang, X. Zhang, G. Wang, J. Shen, G. Zhang, Y. Li, and M. Yan: J. Alloy Compd., 2019, vol. 807, p. 151662.

B. Ruttert, M. Ramsperger, L. Mujica Roncery, I. Lopez-Galilea, C. Körner, and W. Theisen: Mater. Des., 2016, vol. 110, pp. 720–27.

J. Schindelin, I. Arganda-Carreras, E. Frise, V. Kaynig, M. Longair, T. Pietzsch, S. Preibisch, C. Rueden, S. Saalfeld, B. Schmid, J.-Y. Tinevez, D.J. White, V. Hartenstein, K. Eliceiri, P. Tomancak, and A. Cardona: Nat. Methods, 2012, vol. 9, pp. 676–82.

J.C. Yen, F.J. Chang, and S. Chang: IEEE Trans. Image Process., 1995, vol. 4, pp. 370–78.

W. Lenthe, S. Singh, and M.D. Graef: Ultramicroscopy, 2019, vol. 207, p. 112841.

University of Cambridge, Creep mechanisms, https://www.edax.com/products/ebsd/oim-analysis/oim-analysis-v8. Accessed 6 July 2021.

O. Sanchez-Mata, J.A. Muñiz-Lerma, X. Wang, S.E. Atabay, M. Attarian Shandiz, and M. Brochu: Mater. Sci. Eng. A, 2020, vol. 780, p. 139177.

EOS GmbH, EOS Nickel Alloy IN939 Material Data Sheet, Tech. rep. 2021.

L. Carter, Selective Laser Melting of Nickel Superalloys for High Temperature Applications, Ph.D. thesis, University of Birmingham, 2013.

T.-W. Na, W.R. Kim, S.-M. Yang, O. Kwon, J.M. Park, G.-H. Kim, K.-H. Jung, C.-W. Lee, H.-K. Park, and H.G. Kim: Mater. Charact., 2018, vol. 143, pp. 110–17.

N.J. Harrison, I. Todd, and K. Mumtaz: Acta Mater., 2015, vol. 94, pp. 59–68.

M.J. Aziz: J. Appl. Phys., 1982, vol. 53, pp. 1158–68.

R.A. Michi, A. Plotkowski, A. Shyam, R.R. Dehoff, and S.S. Babu: Int. Mater. Rev., 2021, pp. 1–48.

E. Scheil: Z. Metallkd., 1942, vol. 34, pp. 70–72.

M. Ramsperger, L. Mújica Roncery, I. Lopez-Galilea, R.F. Singer, W. Theisen, and C. Körner: Adv. Eng. Mater., 2015, vol. 17, pp. 1486–93.

C. Körner: Int. Mater. Rev., 2016, vol. 61, pp. 361–77.

M.P. Haines, N.J. Peter, S.S. Babu, and E.A. Jägle: Addit. Manuf., 2020, vol. 33, p. 101178.

A.T. Polonsky, M.P. Echlin, W.C. Lenthe, R.R. Dehoff, M.M. Kirka, and T.M. Pollock: Mater. Charact., 2018, vol. 143, pp. 171–81.

A. Després, C. Mayer, M. Veron, E.F. Rauch, M. Bugnet, J.J. Blandin, G. Renou, C. Tassin, P. Donnadieu, and G. Martin: Materialia, 2021, vol. 15, p. 101037.

S. Pourbabak, M.L. Montero-Sistiaga, D. Schryvers, J. Van Humbeeck, and K. Vanmeensel: Mater. Charact., 2019, vol. 153, pp. 366–71.

P. Deng, M. Karadge, R.B. Rebak, V.K. Gupta, B.C. Prorok, and X. Lou: Addit. Manuf., 2020, vol. 35, p. 101334.

G.A. Rao, M. Srinivas, and D. Sarma: Mater. Sci. Eng. A, 2006, vol. 435–436, pp. 84–99.

A.J. Cooper, N.I. Cooper, J. Dhers, and A.H. Sherry: Metall. Mater. Trans. A., 2016, vol. 47A, 4467–75.

A. Suzuki, G.C. Denolf, and T.M. Pollock: Scripta Mater., 2007, vol. 56, pp. 385–88.

A. Suzuki, and T.M. Pollock: Acta Mater., 2008, vol. 56, pp. 1288–97.

Z. Fan, C. Wang, C. Zhang, Y. Yu, H. Chen, and Z. Yang: Mater. Sci. Eng. A, 2018, vol. 735, pp. 114–20.

Z.M. Chen, N.L. Okamoto, M. Demura, and H. Inui: Scripta Mater., 2016, vol. 121, pp. 28–31.

K.V. Vamsi, S.P. Murray, and T.M. Pollock: The yield strength anomaly in Co-Ni design space. in Superalloys 2020. S. Tin, M. Hardy, J. Clews, J. Cormier, Q. Feng, J. Marcin, C. O’Brien, and A. Suzuki, eds., Springer, Berlin, 2020, pp. 948–58.

E.A. Lass: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 2443–59.

X. Lou, P.L. Andresen, and R.B. Rebak: J. Nucl. Mater., 2018, vol. 499, pp. 182–90.

Acknowledgments

The authors gratefully acknowledge funding for this research provided by a Department of Defense (DoD) Vannevar Bush Faculty Fellowship, Grant ONR N00014-18-3031. In addition, tuition and stipend funding was provided to S.P.M. by a DoD National Defense Science and Engineering Graduate Fellowship. The research reported here made use of shared facilities of the National Science Foundation (NSF) Materials Research Science and Engineering Center (MRSEC) at UC-Santa Barbara, DMR-172025. The UC-Santa Barbara MRSEC is a member of the Materials Research Facilities Network (www.mrfn.org). A portion of this research was sponsored by the US Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office, under contract DE-AC05-00OR22725 with UT-Battelle, LLC and performed in partiality at the Oak Ridge National Laboratory’s Manufacturing Demonstration Facility, an Office of Energy Efficiency and Renewable Energy user facility. The authors acknowledge Quintus for HIP treatments applied to alloys in this study. The authors would like to acknowledge James Lamb for developing the python script used to analyze the DTA heating curves.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

UCSB has a pending patent (T.M.P. and S.P.M. as inventors) on SB–CoNi-alloys: High Temperature Oxidation Resistant Co-based Gamma/Gamma Prime Alloys DMREF-Co, US patent application number US16/375,687, publication number US20200140978A1, international patent application number PCT/US2019/025882, international publication number WO2019195612A1. All other authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This manuscript has been authored in part by UT-Battelle, LLC, under contract DE-AC05-00OR22725 with the US Department of Energy (DOE). The US government retains and the publisher, by accepting the article for publication, acknowledges that the US government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for US government purposes. DOE will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Rights and permissions

About this article

Cite this article

Murray, S.P., Raeker, E.B., Pusch, K.M. et al. Microstructure Evolution and Tensile Properties of a Selectively Laser Melted CoNi-Base Superalloy. Metall Mater Trans A 53, 2943–2960 (2022). https://doi.org/10.1007/s11661-022-06716-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06716-z