Abstract

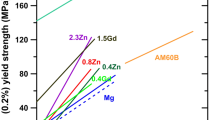

Pure Mg and alloys with 0.4, 1.3, and 3.8 at. pct Gd were cast with grain sizes between 700 and 35 µm and tested in tension and compression after solid solution heat treatment and quenching. The grain structure of the castings was random, that is, there was no preferred orientation, unlike the situation in extrusions and forgings usually reported in the literature. The results are compared to earlier work on Mg-Zn alloys. A tension–compression asymmetry in which the yield strength in compression is less than in tension was observed in pure Mg but was reversed for the concentrated alloys. The Hall–Petch stress intensity factor, k, first increased then decreased with the amount of Gd in solution. It is noted that defining the friction stress by extrapolating the data to infinite grain size should be treated with caution in Mg and its alloys: nevertheless, a rationale involving solid solution softening/hardening and twinning is offered for the observed values of the friction stress. The reversion of the tension–compression asymmetry is explained by the operation of \( \left\{ {10\bar{1}1} \right\} \) (contraction) twinning in the concentrated alloys in place of \( \left\{ {10\bar{1}2} \right\} \) (extension) twinning in pure Mg and the dilute alloys. It is argued that the activation of \( \left\{ {10\bar{1}1} \right\} \) twinning in the more concentrated alloys accounts for their lower k-value.

Similar content being viewed by others

References

E.O. Hall: Proc. Physical Soc. London, 1951, vol. 64, pp. 747-752.

N.J. Petch: J. Iron Steel Institute (London), 1953, vol. 174, pp. 25-28.

F.E. Hauser, P.R. Landon, and J.E. Dorn: Trans. Metall. Soc. AIME, 1956, vol. 206, 589-593.

R.W. Armstrong: The yield and flow stress dependence on polycrystal grain size, in: T.N. Baker (ed.) Yield, flow and fracture of polycrystals, Applied Science Publishers, London, 1983, pp. 1-31.

M.R. Barnett, Z. Keshavarz, A.G. Beer, and D. Atwell: Acta Mater., 2004, vol. 52, pp. 5093-103.

S.R. Agnew: in Advances in Wrought Magnesium Alloys, C. Bettles and M. Barnett, eds., Woodhead Publishing, Cambridge, 2012, pp. 63–104.

C.H. Cáceres, G.E. Mann, and J.R. Griffiths: Metall. Mater. Trans. A, 2011, vol. 42, pp. 1950-1959.

J.H. Woodhead: in T.N. Baker (ed.) Yield, flow and fracture of polycrystals, Applied Science Publishers, London, 1983, pp. 225-233.

T.N. Baker: in T.N. Baker (ed.) Yield, flow and fracture of polycrystals, Applied Science Publishers, London, 1983, pp. 235-273.

U.F. Kocks: Metall. Trans., 1970, vol. 1, pp. 1121-1143.

H. Mecking: in: P. Haasen, V. Gerold, G. Kostorz (eds.) Strength of metals and alloys (ICSMA-5), Pergamon Press, New York, 1979, pp. 1573-1594.

U.F. Kocks and D.G. Westlake: Trans. AIME, 1967, vol. 239, pp. 1107-1109.

T. Sato: Acta Crystall. Section A, 2005, vol. 61, pp. 39-50.

P. Haasen: Physical Metallurgy, Cambridge University Press, Cambridge, 1996.

C.H. Cáceres and A. Blake: Physica Status Solidi (A), 2002, vol. 194, pp. 147-158.

S. Abaspour and C.H. Cáceres: Metall. Mater. Trans. A, 2016, vol. 47, pp. 1313-1321.

S. Abaspour and C.H. Cáceres: Metall. Mater. Trans. A, 2015, vol. 46, pp. 5972-5988.

D.S. Gencheva, A.A. Katsnel’son, L.L. Rokhlin, V.M. Silonov, and F.A. Khavadzha: Fiz. metal. metalloved., 1981, vol. 51, pp. 788-793.

S. Henes and V. Gerold: Zeitschrift fur Metallkunde, 1962, vol. 53, pp. 703-708.

V.M. Silonov, E.V. Evlyukhina, and L.L. Rokhlin: Russian Physics J., 1966, vol. 39, pp. 622-625.

N. Jha and A.K. Mishra: J. Alloys Compounds, 2001, vol. 329, pp. 224-229.

American Society for Metals, Alloy Phase Diagrams Database™. http://www1.asminternational.org/asmenterprise/apd/.

M. Qian, D.H. StJohn, and M.T. Frost: Mater. Sci. Forum, 2003, vols. 419-422, pp. 593-598.

O. Muránsky, D.G. Carr, P. Sittner, and E.C. Oliver: Int. J. Plasticity, 2009, vol. 25, pp. 1107-1127.

M.A. Gharghouri, G.C. Weatherly, J.D. Embury, and J. Root: Phil. Mag. A, 1999, vol. 79, pp. 1671-1696.

S.Y. Lee and M.A. Gharghouri: Mater. Sci. Eng. A, 2013, vol. 572, pp. 98-102.

X.Y. Lou, M. Li, R.K. Boger, S.R. Agnew, and R.H. Wagoner: Int. J. Plasticity, 2007, vol. 23, pp. 44-86.

H. Qiao, S.R. Agnew, and P.D. Wu: Int. J. Plasticity, 2015, vol. 65, pp. 61-84.

International Standard ISO/DIS 6892-1, Metallic Materials-Tensile Testing: Part 1 Method of Test at Room Temperature, 2009.

C.H. Cáceres, T. Sumitomo, and M. Veidt: Acta Mater., 2003, vol. 51, pp. 6211-6218.

G.E. Mann, T. Sumitomo, C.H. Cáceres, and J.R. Griffiths: Mater. Sci. Eng. A, 2007, vol. 456, pp. 138-146.

G.W. Chang, S.Y. Chen, C. Zhou, X.D. Yue, and Y.H. Qi: Trans. Nonferrous Metals Soc. China, 2010, vol. 20, pp. 289-293.

S. Xu, M.A. Gharghouri, and M. Sahoo: Adv. Engineering Mater., 2007, vol. 9, pp. 807-812.

L. Gao, R.S. Chen, and E.H. Han: J.Alloys Compounds, 2009, vol. 481, pp. 379-384.

E.W. Kelley, W.F. Hosford: Trans. Metall. Soc. AIME, 1968, vol. 242, pp. 654-661.

E.W. Kelley, W.F. Hosford: Trans. Metall. Soc. AIME, 1968, vol. 242, pp. 5-13.

S.R. Agnew, M.H. Yoo, and C.N. Tomé: Acta Mater., 2001, vol. 49, pp. 4277-4289.

L. Wu, S.R. Agnew, Y. Ren, D.W. Brown, B. Clausen, G.M. Stoica, H.R. Wenk, and P.K. Liaw: Mater. Sci. Engineering A, 2010, vol. 527, pp. 7057-7067.

J. Zhang, M. Liu, Y. Dou, and G. Liu: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 5499-507.

F. Yang, F. Lv, X.M. Yang, S.X. Li, Z.F. Zhang, and Q.D. Wang: Mater. Sci. Eng. A, 2011, vol. 528, pp. 2231-2238.

B.L. Wu, G. Wan, Y.D. Zhang, and C. Esling: Mater. Letters, 2010, vol. 64, pp. 636-639.

N. Stanford, D. Atwell, and M.R. Barnett: Acta Mater., 2010, vol. 58, pp. 6773-6783.

J. Bohlen, S. Yi, D. Letzig, and K.U. Kainer: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7092-7098.

K. Hantzsche, J. Bohlen, J. Wendt, K.U. Kainer, S.B. Yi, and D. Letzig: Scripta Mater., 2010, vol. 63, pp. 725-730.

J.D. Robson, A.M. Twier, G.W. Lorimer, and P. Rogers: Mater. Sci. Eng. A, 2011, vol. 528, pp. 7247-7256.

N. Stanford: Mater. Sci. Eng. A, 2010, vol. 528, pp. 314-322.

T. Wang, L. Jiang, R. Mishra, and J. Jonas: Metall. Mater. Trans. A, 2014, vol. 45, pp. 4698-4709.

A. Akhtar and E. Teghtsoonian: Acta Metall., 1969, vol. 17, pp. 1351-1356.

A. Kelly and G.W. Groves: Phil. Mag. A, 1963, vol. 8, pp. 877-887.

B. Li and E. Ma: Phys. Rev. Letters, 2009, vol. 103, 035503.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 24, 2015.

Rights and permissions

About this article

Cite this article

Nagarajan, D., Cáceres, C.H. & Griffiths, J.R. Grain Size Hardening Effects in Mg-Gd Solid Solutions. Metall Mater Trans A 47, 5401–5408 (2016). https://doi.org/10.1007/s11661-016-3686-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3686-1