Abstract

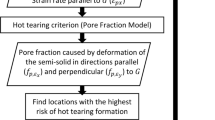

Hot tearing susceptibility is commonly assessed using a pressure drop equation in the mushy zone that includes the effects of both tensile deformation perpendicular to the thermal gradient as well as shrinkage feeding. In this study, a Pore Fraction hot tearing model, recently developed by Monroe and Beckermann (JOM 66:1439–1445, 2014), is extended to additionally include the effect of strain rate parallel to the thermal gradient. The deformation and shrinkage pore fractions are obtained on the basis of the dimensionless Niyama criterion and a scaling variable method. First, the model is applied to the binary Al-Cu system under conditions of directional solidification. It is shown that for the same Niyama criterion, a decrease in the cooling rate increases both the deformation and shrinkage pore fractions because of an increase in the time spent in the brittle temperature region. Second, the model is applied to the industrial aluminum alloy AA5182 as part of a finite element simulation of the Direct Chill (DC) casting process. It is shown that an increase in the casting speed during DC casting increases the deformation and shrinkage pore fractions, causing the maximum point of pore fraction to move towards the base of the casting. These results demonstrate that including the strain rate parallel to the thermal gradient significantly improves the predictive quality of hot tearing criteria based on the pressure drop equation.

Similar content being viewed by others

References

J. Campbell: Castings. 2nd edition, 2003, Oxford, Butterworth-Heinemann.

J. Drezet, M. Rappaz, Y. Krahenbuhl: Mater. Sci. Forum, 1996, vol. 217-222, pp. 305-310.

D.G. Eskin, M. Lalpoor, L. Katgerman: Published in TMS-Light Metals, S.J. Lindsay, ed., TMS, Warrendale, PA, 2011, pp. 669–74.

B. Commet, P. Delaire, J. Rabenberg, et al.: Published in TMS-Light Metals, P.N. Crepeau, ed., TMS, Warrendale, PA, 2003, pp. 711–17

M. Lalpoor, D. G. Eskin, et al.: Mater. Sci. Eng. A, 2011, vol. 528, p. 2831-2842.

J. Grandfeld, P. McGlade: Mater. Sci. Forum. 1996, vol. 20, pp. 29-51.

D.G. Eskin, Q. Du, L. Katgerman: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1206-1212.

D.G. Eskin, L. Katgerman: Mater. Techn., 2009, vol. 24, pp. 152-156.

K. D. Carlson, C. Beckermann: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 163-175.

J. A. Dantzig, M. Rappaz: Solidification. 1st edition, 2009, Lausanne, EPFL Press.

I. Farup, J.M. Drezet, M. Rappaz: Acta Mater., 2001, vol. 49, pp. 1261-1269.

A.B. Phillion, S.L. Cockcroft, P.D. Lee: Mater. Sci. Eng. A, 2008, vol. 491, pp. 237-247.

N. Jamaly, A. B. Phillion, J. M. Drezet: Metall. Mater. Trans. B, 2013, vol. 44B, 1287-1295.

Y. Won, T. Yeo, D. Seol, et al.: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 779-794.

M. Rappaz, J.-M. Drezet, M. Gremaud: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 449-455.

T. Clyne, G. Davies: British Foundryman, 1981, vol. 74, pp. 65-73.

C. Monroe, C. Beckermann: JOM, 2014, vol. 66, pp. 1439-1445.

E. Niyama, T. Uchida, M. Morikawa, and S. Saito: AFS Cast Met. Res. J., 1982, vol. 7, pp. 52–63.

J. Sengupta, S.L. Cockcroft, et al.: Mater. Sci. Eng. A, 2005, vol. 397, pp. 157–77.

J.-M. Drezet and M. Rappaz: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3214–25.

A.W.H. Heijs, C. Lowe: Phys. Rev. E, 1995, vol. 51, pp. 4346-4352.

S. Ergun: Chem. Engg. Prog., 1952, vol. 48, pp. 89-94.

D.G. Eskin, Suyitno, L. Katgerman: Prog. Mater. Sci., 2004, vol. 49, pp. 629-711.

B. Magnin, L. Maenner, et al.: Mater. Sci. Forum, 1996, vol. 217-222, pp. 1209-1214.

A. Yamanaka, K. Nakajima, et al.: Revue Metall.-Cahiers D Inf. Techn., 1992, vol. 89, pp. 627–33.

A. Alankar, M. A. Wells: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7812-7820.

A. B. Phillion, S. L. Cockcroft, P. D Lee: Modell. Simul. Mater. Sci. Eng., 2009, vol. 17, pp. 1-15.

A. M. Glenn, S. P. Russo, P. J. K. Paterson: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 1513-1523.

J.M. Drezet and M. Rappaz: TMS-Light Metals, J.L. Angier, ed., TMS, Warrendale, PA, 2001, pp. 887–93.

H. Hao, D.M. Maijer, et al.: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 2067-2077.

C. Monroe, C. Beckermann: Mater. Sci. Eng. A, 2005, vol. 413-414, pp. 30-36.

Acknowledgment

This work was funded by the China Scholarship Council, and the National Science and Engineering Research Council of Canada.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 7, 2015.

Rights and permissions

About this article

Cite this article

Dou, R., Phillion, A.B. Application of a Pore Fraction Hot Tearing Model to Directionally Solidified and Direct Chill Cast Aluminum Alloys. Metall Mater Trans A 47, 4217–4225 (2016). https://doi.org/10.1007/s11661-016-3590-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3590-8