Abstract

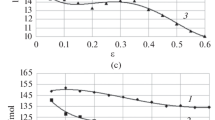

The dimensionless form of the well-known Niyama criterion is extended to include the effect of applied strain. Under applied tensile strain, the pressure drop in the mushy zone is enhanced and pores grow beyond typical shrinkage porosity without deformation. This porosity growth can be expected to align perpendicular to the applied strain and to contribute to hot tearing. A model to capture this coupled effect of solidification shrinkage and applied strain on the mushy zone is derived. The dimensionless Niyama criterion can be used to determine the critical liquid fraction value below which porosity forms. This critical value is a function of alloy properties, solidification conditions, and strain rate. Once a dimensionless Niyama criterion value is obtained from thermal and mechanical simulation results, the corresponding shrinkage and deformation pore volume fractions can be calculated. The novelty of the proposed method lies in using the critical liquid fraction at the critical pressure drop within the mushy zone to determine the onset of hot tearing. The magnitude of pore growth due to shrinkage and deformation is plotted as a function of the dimensionless Niyama criterion for an Al-Cu alloy as an example. Furthermore, a typical hot tear “lambda”-shaped curve showing deformation pore volume as a function of alloy content is produced for two Niyama criterion values.

Similar content being viewed by others

References

J.A. Spittle and A.A. Cushway, Metal Technol. 10, 6 (1983).

R.A. Rosenberg, M.C. Flemings, and H.F. Taylor, AFS Trans. 68, 518 (1960).

S. Li, K. Sadayappan, and D. Apelian, Metall. Mater. Trans. B 44, 614 (2013).

I. Farup, J.-M. Drezet, and M. Rappaz, Acta Mater. 49, 1261 (2001).

G.K. Sigworth, AFS Trans. 155, 1053 (1996).

A.B. Phillion, S.L. Cockcroft, and P.D. Lee, Mater. Sci. Eng. A 491, 237 (2008).

Z. Wang, Y. Huang, A. Srinivasan, Z. Liu, F. Beckmann, K.U. Kainer, and N. Hort, J. Mater. Sci. 49, 353 (2014).

M.G. Pokorny, C.A. Monroe, C. Beckermann, Z. Zhen, and N. Hort, Metall. Mater. Trans. A 41A, 3196 (2010).

D.G. Eskin and L. Katgerman, Metall. Mater. Trans. A 38, 1511 (2007).

M. Rappaz, J.M. Drezet, and M. Gremaud, Metall. Mater. Trans. A 30A, 449 (1999).

K.D. Carlson and C. Beckermann, Metall. Mater. Trans. A 40A, 163 (2009).

E. Niyama, T. Uchida, M. Morikawa, and S. Saito, AFS Cast Met. Res. J. 7, 52 (1982).

W. Kurz and D.J. Fisher, Fundamentals of Solidification, 3rd ed. (Aedermannsdorf: Trans Tech Publications, 1989).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Monroe, C., Beckermann, C. Prediction of Hot Tearing Using a Dimensionless Niyama Criterion. JOM 66, 1439–1445 (2014). https://doi.org/10.1007/s11837-014-0999-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-0999-7