Abstract

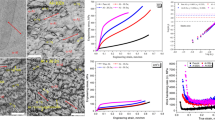

During the production of high-strength 7××× aluminum alloys, hot tearing has set up serious obstacles for attaining a sound billet/slab. In this research, some typical 7××× alloys were studied using constrained rod casting together with the measurement of thermal contraction and load development in the freezing range, aiming at investigating their hot tearing susceptibility. The results showed that the hot tearing susceptibility of an alloy depends not only on the thermal contraction in freezing range, which can decide the accumulated thermal strain during solidification, but also on the amount of nonequilibrium eutectics, which can effectively accommodate the thermally induced deformation. Our investigations reveal that Zn content has very profound effect on hot tearing susceptibility. The Zn/Mg ratio of the alloys also plays a remarkable role though it is not as pronounced as Zn content. The effect of Zn/Mg ratio is mainly associated with the amount of nonequilibrium eutectics. Grain refinement will considerably reduce the hot tearing susceptibility. However, excessive addition of grain refiner may promote hot tearing susceptibility of semi-solid alloy due to deteriorated permeability which is very likely to be caused by the heavy grain refinement and the formation of more intermetallic phases.

Similar content being viewed by others

References

J.C. Williams, E.A. Starke Jr: Acta Mater., 2003, vol. 51, pp. 5775-5799.

W.X. Shu, L.G. Hou, J.C. Liu, C. Zhang, F. Zhang, J.T. Liu, L. Z. Zhuang, J.S. Zhang: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 5375-5392.

I. I. Novikov: Hot Shortness of Non-Ferrous Metals and Alloys, Nauka, Moscow, 1966,.

G. K. Sigworth: AFS Trans., 1996, vol. 104, pp. 1053-1062.

D. G. Eskin, S. Suyitno, L. Katgerman: Prog. Mater. Sci., 2004, vol. 49, pp. 629-711.

W.M. van Haaften, W.H. Kool, and L. Katgerman: J. Mater. Eng. Per., 2002, vol. 11(5), pp. 537-543.

W. I. Pumphrey, J. V. Lyons: J. Inst. Met., 1948, vol. 74(9), pp. 439-447.

D. Viano, D. StJohn, J. Grandfield, C. Cáceres: in Light Metals 2005 (Edited by Halvor Kvande TMS), 2005, pp. 1069–73.

S. Suyitno, D.G. Eskin, V.I. Savran, L. Katgerman: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3551-3561.

J.A. Spittle, A.A. Cushway: Met. Technol., 1983, vol. 10, pp. 6-13.

P. H. Jennings, A. R. E. Singer, W. I. Pumphrey: J. Inst. Met.,1948, vol. 74(7), pp. 227-246.

M.A. Easton, H. Wang, J. Grandfield, C.J. Davidson, D.H. StJohn, L.D. Sweet and M.J. Couper: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 3227-3238.

L. Sweet, J.A. Taylor, M.J. Couper, M.A. Easton: Mater. Sci. Forum, 2011, vol. 693, pp. 217-223.

L. Sweet, J.A. Taylor, M.A. Easton, M.J. Couper, N. Parson: in Light Metals 2012 (Edited by: Carlos E. Suarez TMS), 2012, pp. 1133–38.

D. Warrington and D. G. McCartney: Cast Metals, 1991, vol. 3(4), pp. 202-208.

B. Chamberlain, S. Watanabe: AFS Trans., 1977, vol. 85, pp. 133-142.

G. K. Sigworth, O. Rios, J. Howell, M. Kaufman: AFS Trans., 2004, vol. 112, pp. 387-408.

D. B. Karunakar, R. N. Rai, S. Patra, G. L. Datta: Int. J. Adv. Manuf. Technol., 2009, vol. 45, pp. 851-858.

V. Davies: Brit. Foundryman, 1970, vol. 43, pp. 93-101.

M. Easton, H. Wang, J. Grandfield, D. StJohn, E. Sweet: Mater. Forum, 2004, vol. 28, pp. 224-229.

R. Nadella, D. G. Eskin, and L. Katgerman: in Light Metals 2007 (Edited by Morten Sǿ rlie TMS), 2007, pp. 727–32.

S. Lin, C. Aliravci, and M. O. Pekguleryuz: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1056-1068.

S. Li, K. Sadayappan and D. Apelian: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 614-623.

H. K. Kamga, D. Larouche, M. Bournane, A. Rahem: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7413-7423.

Q. Du, Y. Li: Acta Mater., 2014, vol. 71, pp. 380-389.

X.B. Qi, Y. Chen, X.H. Kang, D.Z. Li, Q. Du: Acta Mater., 2015, vol. 99, pp. 337-346.

D.G. Eskin, S. Suyitno, J.F. Mooney, L. Katgerman: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1325-1335.

H. Nagaumi, G.X. Xue, Z.Z. Zhang Y.L. Ma: Mater. Sci. Forum, 2014, vol. 783-786, pp. 300-306.

M. Lalpoor, D.G. Eskin, L. Katgerman: Mater. Sci. Eng. A, 2008, vol. 497, pp. 186-194.

J.B. Hess: Metall. Trans. A, 1983, vol. 14A, pp. 323-327.

F. D’Elia, C. Ravindran: AFS Trans., 2009, vol. 117, pp. 139-148.

J.B. Mitchell, S.L. Cockcroft, D. Viano, C. Davidson and D. StJohn: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 2503-2512.

W.S. Pellini: Foundry, 1952, vol. 80, pp. 125-133.

M.R. Nasr Esfahani, B. Niroumand: Mater. Charact., 2010, vol. 61, pp. 318-324.

S. Suyitno, W. H. Kool, L. Katgerman: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 2388-2400.

Acknowledgments

This research was supported by The Fundamental Research Funds for the Central Universities (No. FRF-BR-15-078A), Beijing Laboratory of Metallic Materials and Processing for Modern Transportation, Specialized Research Fund for the Doctoral Program of Higher Education (No. 20120006110019), and the Opening Research Fund of State Key Laboratory for Advanced Metals and Materials (Nos. 2012Z-13, 2014ZD-02, 2015-ZD08).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted February 5, 2016.

Rights and permissions

About this article

Cite this article

Bai, Q.L., Li, Y., Li, H.X. et al. Roles of Alloy Composition and Grain Refinement on Hot Tearing Susceptibility of 7××× Aluminum Alloys. Metall Mater Trans A 47, 4080–4091 (2016). https://doi.org/10.1007/s11661-016-3588-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3588-2