Abstract

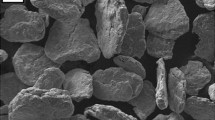

Pre-alloyed ferritic 18Cr steel (Fe-18Cr-2.3W-0.3Ti) powder was milled with and without nano-yttria in high-energy ball mill for varying times until steady-state is reached. The milled powders were consolidated by upset forging followed by hot extrusion. Microstructural changes were examined at all stages of processing (milling, upset forging, and extrusion). In milled powders, crystallite size decreases and hardness increases with increasing milling time reaching a steady-state beyond 5 hours. The size of Y2O3 particles in powders decreases with milling time and under steady-state milling conditions; the particles either dissolve in matrix or form atomic clusters. Upset forged sample consists of unrecrystallized grain structure with few pockets of fine recrystallized grains and dispersoids of 2 to 4 nm. In extruded and annealed rods, the particles are of cuboidal Y2Ti2O7 at all sizes and their size decreased from 15 nm to 5 nm along with significant increase in number density. The oxide particles in ODS6 are of cuboidal Y2Ti2O7 with diamond cubic crystal structure (Fd \( \bar{3} \) m) having a lattice parameter of 10.1 Å and are semicoherent with the matrix. The hardness values of extruded and annealed samples predicted by linear summation model compare well with measured values.

Similar content being viewed by others

References

S. Ukai and M. Fujiwara: J. Nucl. Mater., 2002, vol. 307–311, pp. 749–57.

S.J. Zinkle and J.T. Busby: Mater. Today, 2009, vol. 12, pp. 12–19.

S. Ukai, S. Mizuta, T. Yoshitake, T. Okuda, M. Fujiwara, S. Hagi, and T. Kobayashi: J. Nucl. Mater., 2000, vol. 283–287, pp. 702–06.

A. Alamo, V. Lambard, X. Averty, and M.H. Mathon: J. Nucl. Mater., 2004, vol. 329–333, pp. 333–37.

M.K. Miller, D.T. Hoelzer, E.A. Kenik, and K.F. Russell: Intermetallics, 2005, vol. 13, pp. 387–92.

R.L. Klueh, J.P. Shingledecker, R.W. Swindeman, and D.T. Hoelzer: J. Nucl. Mater., 2005, vol. 341, pp. 103–14.

T. Jayakumar, M.D. Mathew, and K. Laha: Procedia Eng., 2013, vol. 55, pp. 259–70.

8.S. Ohtsuka, S. Ukai, M. Fujiwara, T. Kaito, and T. Narita: Mater. Trans., 2005, vol. 46, pp. 487–92.

S. Ukai: Compr. Nucl. Mater., 2012, vol. 4, pp. 241–71.

G.R. Odette, M.J. Alinger, and B.D Wirth: Annu. Rev. Mater. Res., 2008, vol. 38, pp. 471–503.

M. Ratti, D. Leuvrey, M.H. Mathon, and Y. de Carlan: J. Nucl. Mater., 2009, vol. 386–388, pp. 540-43.

S. Ohtsuka, S. Ukai, M. Fujiwara, T. Kaito, and T. Narita: J. Phys. Chem. Solids, 2005, vol. 66, pp. 571–75.

S. Ohtsuka, S. Ukai, M. Fujiwara, T. Kaito, and T. Narita: J. Nucl. Mater., 2004, vol. 329–333, pp. 372–76.

P. Dou, A. Kimura, R. Kasada, T. Okuda, M. Inoue, S. Ukai, S. Ohnuki, T. Fujisawa, and F. Abe: J. Nucl. Mater., 2013, vol. 442, pp. S95–-S100.

M. Ohnuma, J. Suzuki, S. Ohtsuka, S.-W. Kim, T. Kaito, M. Inoue, and H. Kitazawa: Acta Mater., 2009, vol. 57, pp. 5571–81.

R. Schaublin, A. Ramar, N. Baluc, V. de Castro, M.A. Monge, T. Leguey, N. Schmid, and C. Bonjour, J. Nucl. Mater., 2006, vol. 351, pp. 247–60.

A. Kimura, H.-S. Cho, N. Toda, R. Kasada, K. Yutani, H. Kishimoto, N. Iwata, S. Ukai, and M. Fujiwara: J. Nucl. Sci. Technol., 2007, vol. 44, pp. 323–28.

B. Dousti, R. Mojaver, H.R. Shahverdi, and R.S. Mamoory: J. Alloy. Compd., 2013, vol. 577, pp. 409-16.

A. Pandey, K. Jayasankar, P. Parida, M. Debata, B.K. Mishra, and S. Saroja, Powder Technol., 2014, vol. 262, pp. 162–69

Z. Dapeng, L. Yong, L. Feng, W. Yuren, Z. Liujie, and D. Yuhai: Mater. Lett., 2011, vol. 65, pp. 1672–74.

Y. Liu, J. Fang, D. Liu, Z. Lu, F. Liu, S. Chen, and C.T. Liu: J. Nucl. Mater., 2010, vol. 396, pp. 86–93.

P. Dou, A. Kimura, T. Okuda, M. Inoue, S. Ukai, S. Ohnuki, T. Fujisawa, and F. Abe: J. Nucl. Mater., 2011, vol. 417, pp. 166–70.

S. Ukai, T. Nishida, H. Okada, T. Okuda, M. Fujiwara, and K. Asabe: J. Nucl. Sci. Technol., 1997, vol. 34, pp. 256–63.

R. Delhez, T.H. Keijser, J.I. Langford, D. Louer, E.J. Mittemeijer, and E.J. Snneveld: The Rietveld Method, Oxford University Press, Oxford, 1993, pp. 132–65.

R. Vijay, M. Nagini, J. Joardar, M. Ramakrishna, A.V. Reddy, and G. Sundararajan: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 1611–20.

M. Nagini, R. Vijay, M. Ramakrishna, A.V. Reddy, and G. Sundararajan: Mater. Sci. Eng. A, 2015, vol. 620, pp. 490–99.

J. Wosik, B. Dubial, A. Kruk, H.J. Penkalla, F. Schubert, and A.C. Filemonowicz: Mater. Charact., 2001, vol. 46, pp. 119–23.

D.B. Williams and C.B. Carter: Transmission Electron Microscopy, Plenum Press, New York, 1996.

C. Suryanarayana: Prog. Mater. Sci., 2001, vol. 46, pp. 1–184.

B.S. Murty and S. Ranganathan: Int. Mater. Rev., 1998, vol. 43, pp. 101–144.

J. Gil Sevillano, P. van Houtte, and E. Aernoudt: Prog. Mater. Sci., 1981, vol. 25, pp. 69–412.

H. Zhang, M.J. Gorley, K.B. Chong, M.E. Fitzpatrick, S.G. Roberts, and P.S. Grant: J. Alloy. Compd., 2014, vol. 582, pp. 769–73.

C.A. Williams, P. Unifantowicz, N. Baluc, G.D.W. Smith, and E.A. Marquis: Acta Mater., 2013, vol. 61, pp. 2219–35.

G. Ressel, S. Primig, and H. Leitner: Int. J. Mater. Res., 2013, vol. 104, pp. 1088–95.

M.L. Brocq, F. Legendre, M.-H. Mathon, A. Mascaro, S. Poissonnet, B. Radiguet, P. Pareige, M. Loyer, and O. Leseigneur: Acta Mater., 2012, vol. 60, pp. 7150–59.

36.M.C. Brandes, L. Kovarik, M.K. Miller, and M.J. Mills: J. Mater. Sci., 2012, vol. 47, pp. 3913–23.

C.A. Williams, G.D.W. Smith, and E.A. Marquis: Scripta Mater., 2012, vol. 67, pp. 108–11.

Z. Oksiuta, P. Kozikowski, M. Lewandowska, M. Ohnuma, K. Suresh, and K.J. Kurzydlowski: J. Mater. Sci., 2013, vol. 48, pp. 4620–25.

J. Ribis and Y. de Carlan: Acta Mater., 2012, vol. 60, pp. 238–52.

A. Hirata, T. Fujita, Y.R. Wen, J.H. Schneibel, C.T. Liu, and M.W. Chen: Nat. Mater., 2011, vol. 10, pp. 922–26.

P. Olier, J. Malaplate, M.H. Mathon, D. Nunes, D. Hamon, L. Toualbi, Y. de Carlan, and L. Chaffron: J. Nucl. Mater., 2012, vol. 428, pp. 40–46.

J. Ribis, M.-L. Lescoat, S.Y. Zhong, M.-H. Mathon, and Y. de Carlan: J. Nucl. Mater., 2013, vol. 442, pp. S101–05.

Z. Oksiuta, M. Lewandowska, and K.J. Kurzydłowski: Mech. Mater., 2013, vol. 67, pp. 15–24.

R. Vijay, M. Nagini, S.S. Sarma, M. Ramakrishna, A.V. Reddy, and G. Sundararajan: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 777–84.

J.H. Kim, T.S Byun, D.T. Hoelzer, C.H. Park, J.T. Yeom, and J.K. Hong: Mater. Sci. Eng. A, 2013, vol. 559, pp. 111–18.

Acknowledgments

The authors thank Dr. K. Satya Prasad, Dr. G. Ravichandra, and Dr. J. Joardar for the help in microstructural characterization. The authors also thank Professor D. Banerjee, IISc, Bangalore for the help rendered in HRTEM studies. The authors gratefully acknowledge IGCAR, Kalpakkam for funding (No. IGC/MMG/MMD/ODS/01/2010) the work and NFC, Hyderabad for carrying out hot extrusion.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 23, 2016.

Rights and permissions

About this article

Cite this article

Nagini, M., Vijay, R., Rajulapati, K.V. et al. Effect of Process Parameters on Microstructure and Hardness of Oxide Dispersion Strengthened 18Cr Ferritic Steel. Metall Mater Trans A 47, 4197–4209 (2016). https://doi.org/10.1007/s11661-016-3583-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3583-7