Abstract

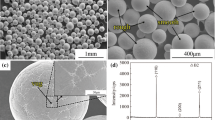

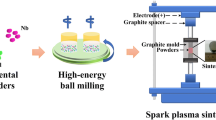

In this paper, the effect of reactive hot press sintering (RHPS) parameters, such as milling time, hot pressing temperature, and heat treatment, on phase constitution, microstructure, and room temperature mechanical properties of a multicomponent Nb-16Si-22Ti-2Hf-2Al-2Cr alloy prepared from ball milled powder mixture is investigated. Evaluation of the microstructure revealed that all as-sintered and heat-treated samples mainly consisted of particles of Nb and Ti solid solutions (NbSS and TiSS), as well as a niobium silicide β-Nb5Si3 matrix, with a small quantity of Hf solid solution particles (HfSS). By sintering at 1773 K and 1873 K (1500 °C and 1600 °C), most of the NbSS phase in the samples prepared from 5 and 10 ball milled powder mixtures showed a narrow strip morphology. Upon increasing the milling time to 20 hours, the morphology changed to a near-equiaxed shape, which became finer with increased milling time. In contrast, the TiSS phase in all as-sintered samples more or less had a near-equiaxed shape. Spheroidizing tendency took place in both NbSS and TiSS phases during an annealing heat treatment at 1773 K (1500 °C) for 50 hours. Interestingly, when the milling time was extended from 5 to 20 hours, the volume fractions of the β-Nb5Si3 and TiSS phases increased, whereas that of the NbSS phase decreased. This resulted in the reduction of the fracture toughness K Q and an enhancement of the Vickers hardness Hv of the bulk as-sintered and heat-treated samples. A fractography analysis was also carried out to elucidate the fracture behavior of phases, with particular emphasis on the interaction between phases and cracks.

Similar content being viewed by others

References

B.P. Bewlay, J.J. Lewandowksi and M.R. Jackson: JOM, 1997, vol. 49, pp. 44-45.

B.P. Bewlay, H.A. Lipsitt, M.R. Jackson, W.J. Reeder, J.A. Sutliff (1995) Mater Sci Eng A 192:534-543.

P.R. Subramanian, M.G. Mendiratta, D.M. Dimiduk: JOM, 1996, vol. 48, pp. 33-38.

J.D. Rigney and J.J. Lewandowksi: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3292-3306.

C.L Ma, H. Tanaka, A. Kasama, R. Tanaka, Y. Mishima and S. Hanada, Proc. High Temperature Ordered Intermetallic Alloys IX, 2001, vol. 646, pp. N5.39.1–39.6.

M. Bannister, H. Shercliff, G. Bao, F. Zok and M.F. Ashby: Acta Metall. Mater., 1992, vol. 40, pp. 1531-1537.

Y. Kimura, Y. Mishima, H. Yamaoka and N. Sekido: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 483-488.

B.P. Bewlay, M.R. Jackson, P.R. Subramanian and J.C. Zhao: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2043-2052.

W.Y. Kim, H. Tanaka and S. Hanada: Intermetallics, 2002, vol. 10, pp. 625-634.

B.P. Bewlay, M.R. Jackson and A. Lipsitt: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3801-3808.

J. Kim, T. Tabaru, M. Sakamoto and S. Hanada: Mater. Sci. Eng. A, 2004, vol. 372A, pp. 137-144.

A.J. Gavens, D.V. Heerden, T. Foecke and T.P. Weihs: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2959-2965.

M.N.R.V. Perdigão, J.A.R. Jordão, C.S. Kiminami and W.J.F. Botta: J. Non-Cryst. Solids, 1997, vol. 219, pp. 170-175.

G.J. Fan, M.X. Quan, Z.Q. Hu, J. Eckert and L. Schultz: Scripta Mater., 1999, vol. 41, pp. 1147-1151.

Z. Li and L.M. Peng: Acta Mater., 2007, vol. 55, pp. 6573-6585.

B.W. Xiong, W.Y. Long, Z. Chen, C. Xia, H. Wan and Y.W. Yan: J. Alloys Compd., 2009, vol. 471, pp. 404-407.

X.L. Wang, G.F. Wang and K.F. Zhang: Mater. Sci. Eng. A, 2010, vol. 527A, pp. 3253-3258.

X.L. Wang, G. Wang and K.F. Zhang: J. Alloys Compd., 2010, vol. 502, pp. 310-318.

J.L. Yu and K.F. Zhang: Scripta Mater., 2008, vol. 59, pp. 714-717.

J.B. Sha, H. Hirai, H. Ueno, T. Tabaru, A. Kitahara, S. Hanada (2003) Metall. Mater. Trans. A 34A:85-94.

J.L. Yu, K.F. Zhang, Z.K. Li, X. Zheng, G.F. Wang and R. Bai: Scripta Mater., 2009, vol. 61, pp. 620-623.

M.G. Mendiratta and D.M. Dimiduk: Metall. Trans. A, 1993, vol. 24A, pp. 501-504.

K.S. Chan (2002) Mater. Sci. Eng. A 329:513-522.

D.L. Davidson, K.S. Chan and D.L. Anton: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3007-3018.

J.B. Sha, H. Hirai, H. Ueno, T. Tabaru, A. Kitahara and S. Hanada: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2861-2871.

C.Y. Yang, Y. Chen and J.B. Sha: Acta Aeronautica et Astronautica Sinica, 2010, vol. 31, pp. 1892-1899 (in Chinese).

J.B. Sha, C.Y. Yang and J. Liu: Scripta Mater., 2010, vol. 62, pp. 859-862.

G. Shao: Intermetallics, 2005, vol. 13, pp. 69-78.

X. Li, H. Chen, J. Sha and H. Zhang: Mater. Sci. Eng. A, 2010, vol. 527A, pp. 6140-6152.

M.F. Ashby, F.J. Blunt and M. Bannister: Acta Metall. Mater., 1989, vol. 37, pp.1847-1857.

Acknowledgments

The authors are grateful to the support from the Program for New Century Excellent Talents in Universities (NCET-06-0173), the National Natural Sciences Foundation of P. R. China (grant no. 51071009 and 51171005), and the Aerospace Funding (grant no. 2010ZF51071).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 18, 2012.

Rights and permissions

About this article

Cite this article

Liu, W., Fu, Y.M. & Sha, J.B. Microstructural Evolution and Mechanical Properties of a Multicomponent Nb-16Si-22Ti-2Al-2Hf-2Cr Alloy Prepared by Reactive Hot Press Sintering. Metall Mater Trans A 44, 2319–2330 (2013). https://doi.org/10.1007/s11661-012-1571-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1571-0