Abstract

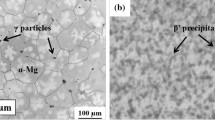

The deformation mechanism in the crack-tip region of a fine-grained Mg-2.4 at. pct Zn binary alloy was investigated by focused ion beam (FIB) and transmission electron microscopy (TEM) observation and finite element analysis (FEA) at the beginning of the fracture toughness test. The deformed microstructure observations showed the formation of subgrains instead of deformation twins in the fracture toughness tested sample, which was performed at a conventional crosshead speed of 1 mm/min. By preventing the formation of deformation twins at the beginning of the test, the crack tip of the fine-grained magnesium alloys became blunted, and thus, the alloys obtained high fracture toughness. Finite element results showed that the temperature increased 50 to 110 K, and the strain rate became two orders of magnitude higher; however, this temperature increment was not sufficient to form high-angle grain boundaries, i.e., a complete occurrence of dynamic recrystallization. On the other hand, the deformed microstructure observations in the sample, which was tested at a crosshead speed of 50 mm/min, showed the formation of nano-order {10-12} deformation twins and subgrains. The formation of deformation twins was caused, in part, by the severe strain from the operation of a high strain rate in the crack-tip region.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

H. Somekawa, A. Singh, and T. Mukai: Scripta Mater., 2007, vol. 56, pp. 1091–94.

H. Yoshinaga and R. Horiuchi: Mater. Trans. JIM, 1963, vol. 4, pp. 1–8.

J. Koike: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1689–96.

H. Somekawa, A. Singh, and T. Mukai: Philo. Mag. Lett., 2009, vol. 89, pp. 2–10.

M.A. Meyers, O. Vohringer, and V.A. Lubarda: Acta Mater., 2001, vol. 49, pp. 4025–39.

D. Lahaie, J.D. Embury, M.M. Chadwick, and G.T. Gray: Scripta Metall., 1992, vol. 27, pp. 139–42.

H. Somekawa, T. Inoue, and T. Mukai: Mater. Sci. Eng. A, 2010, vol. 527, pp. 1761–68.

A. Jain, O. Duygulu, D.W. Brown, C.N. Tome, and S.R. Agnew: Mater. Sci. Eng. A, 2008, vol. 486, pp. 545–55.

Y. Chino, K. Kimura, and M. Mabuchi: Mater. Sci. Eng. A, 2008, vol. 486, pp. 481–88.

M.R. Barnett: Scripta Mater., 2008, vol. 59, pp. 696–99.

N. Nagata, S. Yoshida, and Y. Sekino: J. Jpn. Inst. Met., 1969, vol. 33, pp. 271–75.

D. Hull: Acta Mater., 1961, vol. 9, pp. 191–204.

H. Somekawa and T. Mukai: Scripta Mater., 2005, vol. 53, pp. 1059–64.

H. Somekwa, Y. Osawa, A. Singth, and T. Mukai: J. Mater. Res., 2008, vol. 23, pp. 1128–35.

Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials, ASTM E399, ASTM, West Conshohocken, PA, 2001.

ASM Specialty Handbook, Magnesium and Magnesium Alloys, ASM INTERNATIONAL, Materials Park, OH, 1999, pp. 258–73.

T. Mukai, M. Yamanoi, and K. Higashi: Mater. Trans., 2001, vol. 42, pp. 2652–54.

J. Koike, T. Kobayashi, T. Mukai, H. Watanabe, M. Suzuki, K. Maruyama, and K. Higashi: Acta Mater., 2003, vol. 51, pp. 2055–65.

S.R. Agnew and O. Duygulu: Int. J. Plast., 2005, vol. 21, pp. 1161–93.

S. Hwang, C. Nishimura, and P.G. McCormick: Scripta Mater., 2001, vol. 44, pp. 1507–11.

J. Koike, R. Ohyama, T. Kobayashi, M. Suzuki, and K. Maruyama: Mater. Trans., 2003, vol. 44, pp. 445–51.

H.J. Frost and M.F. Ashby: Deformation-Mechanism Map, Pergamon Press, Oxford, United Kingdom, 1982, p. 44.

T. Sakai and J.J. Jonas: Acta Metall., 1984, vol. 32, pp. 189–209.

The Japan Society for Technology of Plasticity, Forging, Corona-shya, Tokyo, 1991, p. 71.

W.J. Kim, S.J. Yoo, and J.B. Lee: Scripta Mater., 2010, vol. 62, pp. 451–54.

A. Galiyev, R. Kaibyshev, and G. Gottstein: Acta Mater., 2001, vol. 49, pp. 1199–1207.

J.C. Tan and M.J. Tan: Mater. Sci. Eng. A, 2003, vol. 339, pp. 124–32.

S.E. Ion, F.J. Humphreys, and S.H. White: Acta Metall., 1982, vol. 30, pp. 1909–19.

X.Y. Yang, H. Miura, and T. Sakai: Mater. Trans., 2003, vol. 44, pp. 197–203.

D.H. Sastry, Y.V.R.K. Prasad, and K.I. Vasu: Scripta Mater., 1969, vol. 3, pp. 927–30.

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, Pergamon Press, Oxford, United Kingdom, 1996.

R. Kaibyshev and O. Stidikov: Z. Metallkd., 1994, vol. 85, pp. 738–843.

H. Watanabe and K. Ishikawa: Mater. Sci. Eng. A, 2009, vol. 523, pp. 304–11.

M.T. Tucker, M.F. Horstemeyer, P.M. Gullett, H. El. Kadiri, and W.R. Whittington: Scripta Mater., 2009, vol. 60, pp. 182–85.

The Japan Institutes of Metals, Zairyokyodo-no-genshiron, Maruzen, Tokyo, 1985, p. 20.

S.G. Song and G.T. Gray III: Acta Mater., 1995, vol. 43, pp. 2325–37.

W.D. Biggs and P.L. Pratt: Acta Mater., 1958, vol. 6, pp. 694–703.

A. Gilbert, G.T. Hand, C.N. Reid, and B.A. Wilcox: Acta Mater., 1964, vol. 12, pp. 754–55.

D. Ando, J. Koike, and Y. Sutou: Acta Mater., 2010, vol. 58, pp. 4316–24.

L. Lu, Y. Shen, X. Chen, L. Qian, and K. Lu: Science, 2004, vol. 304, pp. 422–26.

E.W. Qin, L. Lu, N.R. Tao, and K. Lu: Scripta Mater., 2009, vol. 60, pp. 539–42.

H. Somekawa, K. Nakajima, A. Singh, and T. Mukai: Phil. Mag. Lett., 2010, vol. 90, pp. 831–39.

Acknowledgments

The authors are grateful to Ms. K. Nakajima and Ms. M. Isaki (National Institute for Materials Science) for the TEM sample preparation by FIB and the experimental help, respectively. This work was supported by a JSPS Grant-in-Aid for Young Scientists (B), Grant No. 21760564.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 9, 2010.

Rights and permissions

About this article

Cite this article

Somekawa, H., Inoue, T., Singh, A. et al. Deformation Mechanism in the Crack-Tip Region of Fine-Grained Magnesium Alloy. Metall Mater Trans A 42, 2475–2480 (2011). https://doi.org/10.1007/s11661-011-0642-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0642-y