Abstract

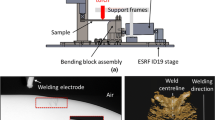

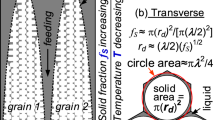

In the present work, mechanisms are proposed for solidification crack initiation and growth in aluminum alloy 6060 arc welds. Calculations for an interdendritic liquid pressure drop, made using the Rappaz–Drezet–Gremaud (RDG) model, demonstrate that cavitation as a liquid fracture mechanism is not likely to occur except at elevated levels of hydrogen content. Instead, a porosity-based crack initiation model has been developed based upon pore stability criteria, assuming that gas pores expand from pre-existing nuclei. Crack initiation is taken to occur when stable pores form within the coherent dendrite region, depending upon hydrogen content. Following initiation, crack growth is modeled using a mass balance approach, controlled by local strain rate conditions. The critical grain boundary liquid deformation rate needed for solidification crack growth has been determined for a weld made with a 16 pct 4043 filler addition, based upon the local strain rate measurement and a simplified strain rate partitioning model. Combined models show that hydrogen and strain rate control crack initiation and growth, respectively. A hypothetical hydrogen strain rate map is presented, defining conceptually the combined conditions needed for cracking and porosity.

Similar content being viewed by others

References

J.C. Lippold: Hot Cracking Phenomena in Welds, Springer-Verlag, Berlin Heidelberg, Germany, 2005, pp. 271–90.

J.C.M. Farrar: Hot Cracking Phenomena in Welds, Springer, New York, NY, 2005, pp. 291–04.

H. Heuser: Hot Cracking Phenomena in Welds, Springer, New York, NY, 2005, pp. 305–27.

J. Campbell: Castings, Butterworth-Heinemann, Oxford, Great Britain, 1991.

R.A. Chihoski: Weld. J., 1972, vol. 51 (1), pp. 9s–18s.

T. Zacharia: Weld. J., 1994, vol. 73 (7), pp. 164s–172s.

Z. Feng: Weld. World, 1994, vol. 33, pp. 340–47.

D.G. Eskin, W.H. Suyitno, and L. Katgerman: Progr. Mater. Sci., 2004, vol. 49, pp. 629–711.

D.G. Eskin and L. Katgerman: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1511–19.

Suyitno, W.H. Kool, and L. Katgerman: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1537–46.

C.E Cross: Hot Cracking Phenomena in Welds, Springer, New York, NY, 2005, pp. 3–18.

C.E. Cross and N. Coniglio: Hot Cracking Phenomena in Welds II, Springer, New York, NY, 2008, pp. 39–58.

M. Rappaz, J.-M. Drezet, and M. Gremaud: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 449–55.

V.N. Saveiko: Russ. Cast. Prod., 1961, (11), pp. 453–56.

C.H. Dickhaus, L. Ohm, and S. Engler: AFS Trans., 1994, vol. 101, pp. 677–84.

D.J. Lahaie and M. Bouchard: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 697–705.

W.S. Pellini: Foundry, 1952, vol. 80, pp. 125–99.

N.N. Prokhorov: Svar. Proiz., 1956, vol. 6, pp. 5–11.

T. Senda, F. Matsuda, G. Takano, K. Watanabe, T. Kobayashi, and T. Matsuzaka: Trans. JWS, 1971, vol. 2 (2), pp. 141–62.

W.I. Pumphrey and P.H. Jennings: J. Inst. Met., 1948, vol. 75, pp. 235–56.

J.C. Borland: Brit. Weld. J., 1961, vol. 8, pp. 526–40.

U. Feurer: Proc. Int. Symp. Eng. Alloys, Delft University of Technology, Delft, The Netherlands, 1977, pp. 131–45.

J.C. Fisher: J. Appl. Phys., 1948, vol. 19, pp. 1062–67.

H. Murakawa, H. Serizawa, and M. Shibahara: Mathematical Modelling of Weld Phenomena 7, TU Graz, Graz, Austria, 2005, pp. 539–54.

J.A. Williams and A.R.E. Singer: J. Inst. Met., 1968, vol. 96, pp. 5–12.

J.F. Grandfield, C.J. Davidson, and J.A. Taylor: Light Metals 2001, TMS, Warrendale, PA, 2001, pp. 895–901.

M. Braccini, C.L. Martin, M. Suéry, and Y. Bréchet: Modeling of Casting, Welding, and Advanced Solidification Processes IX, Shaker Verlag, Aachen, Germany, 2000, pp. 19–24.

M. Braccini, C.L. Martin, M. Suéry, and Y. Bréchet: Mater. Techniq., 2000, vols. 5–6, pp. 19–24.

C.V. Robino, M. Reece, G.A. Knorovsky, J.N. DuPont, and Z. Feng: Proc. 7th Int. Conf. Trends in Welding Research, ASM INTERNATIONAL, Materials Park, OH, 2005, pp. 313–18.

N. Coniglio, C.E. Cross, T. Michael, and M. Lammers: Weld. J., 2008, vol. 87 (8), pp. 237s–247s.

N. Coniglio: Doctoral Thesis, Otto-von-Guericke University, Magdeburg, Germany, BAM, Berlin, Germany, 2008.

L. Bäckerud, E. Krol, and J. Tamminen: Solidification Characteristics of Aluminum Alloys, Skanaluminum, Oslo, Norway, vol. 1, 1986, pp. 63–74.

B.T. Alexandrov and J.C. Lippold: IIW Doc. IX-2163-05, International Institute of Welding, Paris, France, 2005.

N. Coniglio and C.E. Cross: Weld. World, 2006, vol. 50 (11–12), Doc. IIW-1755-06, pp. 14–23.

N. Coniglio, C.E. Cross, I. Dörfel, and W. Österle: Mater. Sci. Eng., A, 2009, vol. 517, pp. 321–27.

L.F. Mondolfo: Aluminum Alloys—Structure & Properties, Butterworth and Co., London, 1976, p. 63.

Aluminum, Vol. 1: Properties, Physical Metallurgy, and Phase Diagrams, K.R. Van Horn, ed., ASM, Metals Park, OH, 1967.

S. Ganesan, C.L. Chan, and D.R. Poirier: Mater. Sci. Eng., A, 1992, vol. A151, pp. 97–105.

D.E.J. Talbot: The Effects of Hydrogen in Aluminum and Its Alloys, Maney Publishing, London, 2004.

M. Rappaz, A. Jacot, and W.J. Boettinger: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 467–79.

D. Warrington and D.G. McCartney: Cast Met., 1989, vol. 2 (3), pp. 134–43.

M.G. Mousavi, C.E. Cross, and Ø. Grong: Sci. Technol. Weld. Joining, 1999, vol. 4 (6), pp. 381–88.

M.J. Dvornak, R.H. Frost, and D.L. Olson: Weld. J., 1989, vol. 68 (8), pp. 327s–337s.

L.A. Tarshis, J.L. Walker, and J.W. Rutter: Metall. Trans., 1971, vol. 2, pp. 2589–97.

J. Campbell: The Solidification of Metals, Iron and Steel Institute, London, 1968, pp. 18–26.

R.A. Woods: Weld. J., 1974, vol. 53 (3), pp. 97s–108s.

R.P. Martukanitz and P.R. Michnuk: Trends in Welding Research, ASM, Metals Park, OH, 1982, pp. 315–30.

G. Huismann, F. Wittemann, T. Behrendt, and H. Krüger: IIW Doc. Commission IX, International Institute of Welding, Paris, France, 2004.

D.E.J. Talbot and D.A. Granger: J. Inst. Met., 1963–1964, vol. 92, pp. 290–97.

H. Toda, T. Hidaka, K. Minami, M. Kobayashi, K. Uesugi, Y. Suzuki, and T. Kobayashi: Proc. 11th Int. Conf. on Aluminum Alloys, Wiley-VCH, Weinheim, Germany, 2008, pp. 575–581.

J. Campbell: Brit. J. Appl. Phys., 1968, vol. 1 (2), pp. 1085–88.

S.N. Tiwari and J. Beech: Met. Sci., 1978, pp. 356–62.

N. Coniglio and C.E. Cross: Hot Cracking Phenomena in Welds II, Springer, New York, NY, 2008, pp. 277–310.

H. Tamura, N. Kato, S. Ochiai, and Y. Katagiri: Trans. JWS, 1997, vol. 8 (2), pp. 16–22.

Y. Arata, F. Matsuda, K. Nakata, and K. Shinozaki: Trans. JWRI, 1977, vol. 6, pp. 91–104.

F. Matsuda, H. Nakagawa, K. Nakata, and H. Okada: Trans. JWRI, 1979, vol. 8, pp. 85–95.

C.E. Cross and D.L. Olson: Proc. Int. Conf. on Aluminum Alloys: Physical and Mechanical Properties, University of Virginia, Charlottesville, Virginia, 1986, vol. III, pp. 1869–75.

C.E. Cross, D.L. Olson, and G.R. Edwards: Int. Conf. Proc. on Modeling and Control of Joining Processes, American Welding Society, Miami, FL, 1993, pp. 549–57.

R. Otsuka: Handbook of Aluminum, Vol. 1: Physical Metallurgy and Processes, Marcel Dekker, New York, NY, 2003, p. 661.

B. Dixon: IIW Asian Pacific Regional Welding Congress, Hobart, TAS, Australia, 1988, pp. 731–51.

Acknowledgment

The authors are grateful to BAM for providing internal funding for this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 14, 2008.

Rights and permissions

About this article

Cite this article

Coniglio, N., Cross, C. Mechanisms for Solidification Crack Initiation and Growth in Aluminum Welding. Metall Mater Trans A 40, 2718–2728 (2009). https://doi.org/10.1007/s11661-009-9964-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9964-4