Abstract

Hot tearing in castings is closely related to the difficulty of bridging or coalescence of dendrite arms during the last stage of solidification. The details of the process determine the temperature at which a coherent solid forms; i.e., a solid that can sustain tensile stresses. Based on the disjoining-pressure concept used in fluid dynamics, a theoretical framework is established for the coalescence of primary-phase dendritic arms within a single grain or at grain boundaries. For pure substances, approaching planar liquid/solid interfaces coalesce to a grain boundary at an undercooling (ΔT b ), given by

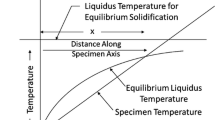

where δ is the thickness of an isolated solid-liquid interface, and ΔГ b is the difference between the grain-boundary energy, γ gb , and twice the solid/liquid interfacial energy, 2γ sl , divided by the entropy of fusion. If γ gb <2γ sl , then ΔT b <0 and the liquid film is unstable. Coalescence occurs as soon as the two interfaces get close enough (at a distance on the order of δ). This situation, typical of dendrite arms belonging to the same grain (i.e., γ gb =0), is referred to as “attractive”. The situation where γ gb =2 γ sl is referred to as “neutral”; i.e., coalescence occurs at zero undercooling. If γ gb >2γ sl , the two liquid/solid interfaces are “repulsive” and ΔT b >0. In this case, a stable liquid film between adjacent dendrite arms located across such grain boundaries can remain until the undercooling exceeds ΔT b . For alloys, coalescence is also influenced by the concentration of the liquid film. The temperature and concentration of the liquid film must reach a coalescence line parallel to, but ΔT b below, the liquidus line before coalescence can occur. Using one-dimensional (1-D) interface tracking calculations, diffusion in the solid phase perpendicular to the interface (backdiffusion) is shown to aid the coalescence process. To study the interaction of interface curvature and diffusion in the liquid film parallel to the interface, a multiphase-field approach has been used. After validating the method with the 1-D interface tracking results for pure substances and alloys, it is then applied to two-dimensional (2-D) situations for binary alloys. The coalescence process is shown to originate in small necks and involve rapidly changing liquid/solid interface curvatures.

Similar content being viewed by others

References

T.W. Clyne and G.J. Davies: Br. Foundryman, 1975, vol. 68, p. 238.

M. Rappaz, J.-M. Drezet, and M. Gremaud: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 449–55.

A.K. Chesters: Chem. Eng. Res. Des., 1991, vol. 69, pp. 259–70.

P.T. Jaeger, J.J.M. Janssen, F. Groeneweg, and W.G.M. Agterof: Coll. Surf. A: Physiochem. Eng. Aspects, 1994, vol. 85, pp. 255–64.

D.P. Woodruff: The Solid-Liquid Interface, Cambridge University Press, London, 1973, pp. 67–73.

G.F. Bolling: Acta Metall., 1968, vol. 16, pp. 1147–57.

J.G. Dash: Contemp. Phys., 1989, vol. 30, p. 89.

J.W. Cahn, J.G. Dash, and H. Fu: J. Cryst. Growth, 1992, vol. 123, pp. 101–08.

A. Chernov, D.E. Tempkin, and A.M. Melnikova: Sov. Phys. Crystallogr., 1976, vol. 21, p. 369.

D.M. Stefanescu and B.K. Dhindaw: in Metals Handbook, vol. 15, Solidification, ASM INTERNATIONAL, Metals Park, OH, 1988, p. 142.

M.A. Azouni and P. Casses: Adv. Coll. Interface Sci., 1998, vol. 75, pp. 83–106.

W.A. Miller and G.A. Chadwick: Acta Metall., 1967, vol. 15, p. 607.

D.A. Porter and K.E. Easterling: Phase Transformations in Metals and Alloys, Van Nostrand Reinhold, Berkshire, United Kingdom, 1981, p. 122.

B. Nestler and A.A. Wheeler: Physica D, 2000, vol. 138, p. 114.

H. Combeau, A. Mo, J.-M. Drezet, and M. Rappaz: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2314–27.

R. Kobayashi, J.A. Warren, and W.C. Carter: Physica D, 2000, vol. 140, pp. 141–50.

J. Tiaden, B. Nestler, H.J. Diepers, and I. Steinbach: Physica D, 1998, vol. 115, pp. 73–86.

J.A. Warren and W.J. Boettinger: Acta Mater., 1995, vol. 43, pp. 689–703.

H. Garcke, B. Nestler, and B. Sloth: SIAM J. Appl. Math., 1999, vol. 60, pp. 295–315.

W.J. Boettinger and J.A. Warren: Proc. Merton C. Flemings Symp. on Solidification and Material Processing, R. Abbaschian, H. Brody, and A. Mortensen, eds., TMS, Warrendale, PA, 2001, pp. 101–12.

Author information

Authors and Affiliations

Additional information

This article is based on a presentation given in the symposium “Fundamentals of Solidification” which occurred at the TMS Fall meeting in Indianapolis, Indiana, November 4–8, 2001, under the auspices of the TMS Solidification Committee.

Rights and permissions

About this article

Cite this article

Rappaz, M., Jacot, A. & Boettinger, W.J. Last-stage solidification of alloys: Theoretical model of dendrite-arm and grain coalescence. Metall Mater Trans A 34, 467–479 (2003). https://doi.org/10.1007/s11661-003-0083-3

Issue Date:

DOI: https://doi.org/10.1007/s11661-003-0083-3