Abstract

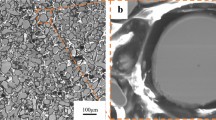

The changes of the microstructure and the mechanical properties of FeCrMoCBY amorphous coatings prepared by plasma spraying after heat treatment were investigated. 300, 400, 500 and 600 °C were selected as the heat treatment temperature, and the crystallization phenomenon occurred after the heat treatment at 600 °C. The crystallization products of the coating heat-treated at 600 °C were α-Fe and Fe23(C, B)6. Heat treatment was beneficial to the microhardness and the bonding strength of the coatings. The microhardness of the coating heat-treated at 600 °C increased obviously, and the strongest bonding strength occurred in the coating heat-treated at 500 °C. The improvement of the wear resistance of the coatings could attribute to heat treatment as well, and the wear resistance of the coating heat-treated at 600 °C was the optimum, compared with the coating heat-treated at 500 °C.

Similar content being viewed by others

References

Jiang C, Liu W, Wang G, et al. The Corrosion Behaviours of Plasma-sprayed Fe-based Amorphous Coatings[J]. Surf. Eng., 2018; 34(8): 634–639

Jiang C, Chen H, Wang G, et al. Improvements in Microstructure and Wear Resistance of Plasma-sprayed Fe-based Amorphous Coating by Laser-remelting[J]. J. Therm. Spray Techn., 2017, 26(4): 778–786

Suryanarayana C, Inoue A. Iron-based Bulk Metallic Glasses[J]. Int. Mater. Rev., 2013; 58(3): 131–166

Fu B Y, He D Y, Zhao L D, et al. Microstructure and Properties of Arc Sprayed Coatings Containing Fe-based Amorphous Phase[J]. Surf. Eng., 2009, 25(4): 333–337

Li R F, Zheng Q C, Zhu Y Y, et al. Experimental Study of the Microstructure and Micromechanical Properties of Laser Cladded Ni-based Amorphous Composite Coatings[J]. J. Mater. Eng. Perform., 2018, 27(1): 80–88

Jiang C P, Xing Y Z, Zhang F Y, et al. Wear Resistance and Bond Strength of Plasma Sprayed Fe/Mo Amorphous Coatings[J]. J. Iron Steel Res. Int., 2014, 21(10): 969–974

Kumar A, Nayak S K, Bijalwan P, et al. Mechanical and Corrosion Properties of Plasma-Sprayed Fe-based Amorphous/Nanocrystalline Composite Coating[J]. Adv. Mater. Process Technol., 2019; 5(2): 371–377

Zhou Z, Wang L, He D Y, et al. Microstructure and Electrochemical Behavior of Fe-based Amorphous Metallic Coatings Fabricated by Atmospheric Plasma Spraying[J]. J. Therm. Spray Techn., 2011; 20(1–2): 344–350

Jiang C P, Xing Y Z, Zhang F Y, et al. Microstructure and Corrosion Resistance of Fe/Mo Composite Amorphous Coatings Prepared by Air Plasma Spraying[J]. Int. J. Min. Met. Mater., 2012, 19(7): 657–662

Wang M Q, Zhou Z H, Wang Q J, et al. Long Term Semiconducting and Passive Film Properties of a Novel Dense FeCrMoCBY Amorphous Coating by Atmospheric Plasma Spraying[J]. Appl. Surf. Sci., 2019, 495: 143 600

Zhang S D, Wu J, Qi W B, et al. Effect of Porosity Defects on the Long-term Corrosion Behaviour of Fe-based Amorphous Alloy Coated Mild Steel[J]. Corros. Sci., 2016, 110: 57–70

Dong Y, Fan L, Chen H, et al. Corrosion Behavior of Plasma Transferred Arc Fe-based Coating Reinforced by Spherical Tungsten Carbide in Hydrochloric Acid Solutions[J]. J. Wuhan Univ. Technol.-Mat. Sci. Ed., 2020, 35: 299–309

Mouadji Y, Bradai M A, Younes R, et al. Influence of Heat Treatment on Microstructure and Tribological Properties of Flame Spraying Fe-Ni-Al Alloy Coating[J]. J. Cent. South Univ., 2018, 25(3): 473–481

Dhakar B, Namdeo A, Chatterjee S, et al. Heat Treatment of Plasma Sprayed Alumina-Chromia Composite Coatings[J]. Surf. Eng., 2018, 34(10): 737–746

Ma H R, Chen X Y, Li J W, et al. Fe-based Amorphous Coating with High Corrosion and Wear Resistance[J]. Surf. Eng., 2017; 33(1): 56–62

Wang X, Xu J H, Ma S L, et al. Effects of Annealing Temperature on the Microstructure and Hardness of TiAlSiN Hard Coatings[J]. Chinese Sci. Bull., 2011, 56(16): 116–120

Jiang C, Wang J, Han J, et al. Effect of Laser Remelting on the Microstructure and Corrosion Resistance of Plasma Sprayed Fe-based Coating[J]. J. Wuhan Univ. Technol.-Mat. Sci. Ed., 2015, 30: 804–807

Zhang B, Dong Q, Zhu N, et al. Microstructure and Wear Behaviors of Plasma-sprayed FeCrNiMoCBSi Coating with Nano-Grain Dispersed Amorphous Phase in Reciprocating Sliding Contact[J]. Tribol. T, 2019, 62(2): 274–282

Çiçek H. Structural and Tribological Characterization of Amorphous and Crystalline Titanium-Nickel Coatings[J]. J. Adhes. Sci. Technol., 2019, 33(6):635–645

Yodoshi N, Ookawa S, Yamada R, et al. Effects of Nanocrystallisation on Saturation Magnetisation of Amorphous Fe76Si9B10P5[J]. Mater. Res. Lett., 2018, 6(1): 100–105

Meng G H, Zhang B Y, Liu H, et al. Vacuum Heat Treatment Mechanisms Promoting the Adhesion Strength of Thermally Sprayed Metallic Coatings[J]. Surf. Coat. Tech., 2018, 344: 102–110

Jiang C, Xing Y, Hao J. Effect of Heat Treatment on Plasma-Sprayed Mo-based Amorphous and Nanocrystalline Coating[J]. J. Comput. Theor. Nanos., 2012, 9(9): 1434–1437

Tarasi F, Medraj M, Dolatabadi A, et al. High-Temperature Performance of Alumina-Zirconia Composite Coatings Containing Amorphous Phases[J]. Adv. Funct. Mater., 2011, 21(21): 4143–4151

Ma H R, Li J W, Jiao J, et al. Wear resistance of Fe-based Amorphous Coatings Prepared by AC-HVAF and HVOF[J]. Mater. Sci. and Tech., 2016, 33(1): 65–71

Fu B Y, He D Y, Zhao L D. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Fe-based Amorphous Coatings[J]. J. Alloy Compd., 2009, 480(2): 422–427

Wu N C, Chen K, Sun W H, et al. Correlation between Particle Size and Porosity of Fe-based Amorphous Coating[J]. Surf. Eng., 2019, 35(1): 37–45

Wang G, Zhou Z, Wang Z, et al. Effect of Heat Treatment in Air on Bonding Strength and Micro-structure of Al2O3-13 wt%TiO2/NiCrAl Coating Prepared by Air Plasma-spray Process[J]. Prot. Met. and Phys. Chem., 2016, 52(6): 1064–1069

Funding

Funded by National Natural Science Foundation of China (No. 51379070)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, L., Zhou, Z., Dend, Y. et al. Influence of Heat Treatment on Microstructure and Mechanical Properties of Plasma Sprayed FeCrMoCBY Amorphous Coatings. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 36, 761–765 (2021). https://doi.org/10.1007/s11595-021-2469-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-021-2469-8