Abstract

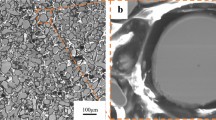

In this work, Fe-10Cr-10Mo-4B-2C-4P (wt.%) amorphous/nanocrystalline multilayered coatings were synthesized using the atmospheric plasma spraying method with different power/heat input to vary the degree of melting. Microstructural and compositional characterization results showed that both amorphicity and porosity decreased with increasing plasma power. Higher hardness was observed at elevated power due to the presence of less porosity and more amount of hard intermetallic phases in the amorphous matrix. Wear behavior of the coatings was investigated under two different modes viz. reciprocating mode and unidirectional rotating mode to reflect the real-life service conditions. Results of dry sliding wear test revealed that improved wear resistance for coatings synthesized at higher plasma power input is attributed to the formation of well-adhered splats and presence of higher amount of intermetallic phases. Interestingly, the specific wear rate and coefficient of friction values obtained by performing the wear test in rotating mode were lower compared to that in reciprocating mode. Most importantly, a transition in wear mechanism was envisaged as mode of wear changes, i.e., fatigue dominated in case of the reciprocating mode to abrasion dominated in the rotating mode.

Similar content being viewed by others

References

Q. Dong, J. Tan, R. Huang, H.L. Wang, P. Song, C.J. Li, Z.X. Feng, M. Calin and J. Eckert, Nanoindentation Creep Behavior of an Fe–Cr–Mo–B–C Amorphous Coating via Atmospheric Plasma Spraying, Intermetallics, 2022, 141, p 107411. https://doi.org/10.1016/j.intermet.2021.107411

J.J. Kruzic, Bulk Metallic Glasses as Structural Materials: A Review, Adv. Eng. Mater., 2016, 18(8), p 1308-1331. https://doi.org/10.1002/adem.201600066

C. Suryanarayana and A. Inoue, Bulk Metallic Glasses, 2nd ed. CRC Press, Boca Raton, 2017. https://doi.org/10.1201/9781315153483

M. Miller and P. Liaw, Bulk Metallic Glasses: An Overview, 1st ed. Springer, New York, 2008. https://doi.org/10.1007/978-0-387-48921-6

N. Li, J. Zhang, W. Xing, D. Ouyang and L. Liu, 3D Printing of Fe-Based Bulk Metallic Glass Composites with Combined High Strength and Fracture Toughness, Mater. Des., 2018, 143, p 285-296. https://doi.org/10.1016/j.matdes.2018.01.061

S.K. Nayak, A. Kumar and T. Laha, Developing an Economical Wear and Corrosion Resistant Fe-Based Metallic Glass Composite Coating by Plasma and HVOF Spraying, J. Therm. Spray Tech., 2022, 31, p 1317-1329. https://doi.org/10.1007/s11666-021-01277-w

A. Inoue, F.L. Kong, S.L. Zhu, E. Shalaan and F.M. Al-Marzouki, Production Methods and Properties of Engineering Glassy Alloys and Composites, Intermetallics, 2015, 58, p 20-30. https://doi.org/10.1016/j.intermet.2014.11.001

S.K. Nayak, A. Kumar and T. Laha, Fe-Based Metallic Glass Coatings by Thermal Spraying: A Focused Review on Corrosion Properties and Related Degradation Mechanisms, Int. Mater. Rev., 2023, 68(4), p 404-485. https://doi.org/10.1080/09506608.2022.2084670

W.J. Botta, J.E. Berger, C.S. Kiminami, V. Roche, R.P. Nogueira and C. Bolfarini, Corrosion Resistance of Fe-Based Amorphous Alloys, J. Alloys Compd., 2014, 586(1), p S105-S110. https://doi.org/10.1016/j.jallcom.2012.12.130

Z. Chu, W. Deng, X. Zheng, Y. Zhou, C. Zhang, J. Xu and L. Gao, Corrosion Mechanism of Plasma-Sprayed Fe-Based Amorphous Coatings with High Corrosion Resistance, J. Therm. Spray Tech., 2020, 29(5), p 1111-1118. https://doi.org/10.1007/s11666-020-01030-9

P. Bijalwan, A. Kumar, S.K. Nayak, A. Banerjee, M. Dutta and T. Laha, Microstructure and Corrosion Behavior of Fe-Based Amorphous Composite Coatings Developed by Atmospheric Plasma Spraying, J. Alloys Compd., 2019, 796, p 47-54. https://doi.org/10.1016/j.jallcom.2019.05.046

J. Zhou, X. Wang, J. You, J. Pang, X. Li and K. Qiu, Excellent Soft Magnetic Properties and Enhanced Glass Forming Ability of Fe-Si-B-C-Cu Nanocrystalline Alloys, J. Alloys Compd., 2022, 918, p 165538. https://doi.org/10.1016/j.jallcom.2022.165538

D. Muraca, J. Silveyra, M. Pagnola and V. Cremaschi, Nanocrystals Magnetic Contribution to FINEMET-Type Soft Magnetic Materials with Ge Addition, J. Magn. Magn. Mater., 2009, 321(21), p 3640-3645. https://doi.org/10.1016/j.jmmm.2009.07.005

F.C. Li, T. Liu, J.Y. Zhang, S. Shuang, Q. Wang, A.D. Wang, J.G. Wang and Y. Yang, Amorphous-Nanocrystalline Alloys: Fabrication, Properties, and Applications, Mater. Today Adv., 2019, 4, p 100027. https://doi.org/10.1016/j.mtadv.2019.100027

L. Shi, X. Qin and K. Yao, Tailoring Soft Magnetic Properties of Fe-Based Amorphous Alloys through C Addition, Prog. Nat. Sci. Mater. Int., 2020, 30(2), p 208-212. https://doi.org/10.1016/j.pnsc.2020.02.001

Z.B. Jiao, H.X. Li, J.E. Gao, Y. Wu and Z.P. Lu, Effects of Alloying Elements on Glass Formation, Mechanical and Soft-Magnetic Properties of Fe-Based Metallic Glasses, Intermetallics, 2011, 19(10), p 1502-1508. https://doi.org/10.1016/j.intermet.2011.05.020

S.K. Nayak, M.A. Faridi, G.M.A. Kumar and T. Laha, Fe-Based Metallic Glass Composite Coatings by HVOF Spraying: Influence of Mo on Phase Evolution, Wear and Corrosion Resistance, Mater. Charact., 2022, 191, p 112149. https://doi.org/10.1016/j.matchar.2022.112149

S.L. Wang, H.X. Li, X.F. Zhang and S. Yi, Effects of Cr Contents in Fe-Based Bulk Metallic Glasses on the Glass Forming Ability and the Corrosion Resistance, Mater. Chem. Phys., 2009, 113(2–3), p 878-883. https://doi.org/10.1016/j.matchemphys.2008.08.057

E. Coleman, Crystallization of Fe, Co and Ni Based Metallic Glasses, Mater. Sci. Eng., 1976, 23(2–3), p 161-167. https://doi.org/10.1016/0025-5416(76)90187-7

Ł Szczepański, M. Bambach, F. Jensch, A. Ambroziak and T. Kurzynowski, Structural Investigations of Fe-Zr-Si-Cu Metallic Glass with Low Glass-Forming Ability Produced in Laser Powder Bed Fusion Technology, Mater. Des., 2021, 210, p 110112. https://doi.org/10.1016/j.matdes.2021.110112

M. Naka, Effect of Metalloidal Elements on the Microhardness of Iron-Base Glasses, J. Appl. Phys., 1980, 51(11), p 6006-6009. https://doi.org/10.1063/1.327522

M. Hasiak, M. Tkaczyk, A. Łaszcz and J. Olszewski, Effect of Alloying Additions on Microstructure, Mechanical and Magnetic Properties of Rapidly Cooled Bulk Fe-B-M-Cu (M = Ti, Mo and Mn) Alloys, Metall. Mater. Trans. A, 2022, 53(2), p 556-572. https://doi.org/10.1007/s11661-021-06530-z

C. Zhang, Q. Li, L. Xie, G. Zhang, B. Mu, C. Chang, H. Li and X. Ma, Development of Novel Fe-Based Bulk Metallic Glasses with Excellent Wear and Corrosion Resistance by Adjusting the Cr and Mo Contents, Intermetallics, 2023, 153, p 107801. https://doi.org/10.1016/j.intermet.2022.107801

B. Huang, C. Zhang, G. Zhang and H. Liao, Wear and Corrosion Resistant Performance of Thermal-Sprayed Fe-Based Amorphous Coatings: A Review, Surf. Coat. Technol., 2019, 377, p 124896. https://doi.org/10.1016/j.surfcoat.2019.124896

S.F. Guo, L. Liu, N. Li and Y. Li, Fe-Based Bulk Metallic Glass Matrix Composite with Large Plasticity, Scripta Mater., 2010, 62(6), p 329-332. https://doi.org/10.1016/j.scriptamat.2009.10.024

Z. Li, Z. Liu, Y. Wang, S. Liu, R. Jiang and Y. Wang, Fe-Based Amorphous Composite Coating Prepared by Plasma Remelting, Adv. Mater. Sci. Eng., 2015, 2015, p 375213. https://doi.org/10.1155/2015/375213

M. Komaki, T. Mimura, Y. Kusumoto, R. Kurahasi, M. Kouzaki and T. Yamasaki, Formation of Fe-Based Amorphous Coating Films by Thermal Spraying Technique, Mater. Trans., 2010, 51(9), p 1581-1585. https://doi.org/10.2320/matertrans.MAW201022

W. Guo, Y. Wu, J. Zhang, S. Hong, G. Li, G. Ying, J. Guo and Y. Qin, Fabrication and Characterization of Thermal-Sprayed Fe-Based Amorphous/Nanocrystalline Composite Coatings: An Overview, J. Therm. Spray Technol., 2014, 23(7), p 1157-1180. https://doi.org/10.1007/s11666-014-0096-z

V. Varadaraajan, R.K. Guduru and P.S. Mohanty, Synthesis and Microstructural Evolution of Amorphous/Nanocrystalline Steel Coatings by Different Thermal-Spray Processes, J. Therm. Spray Technol., 2013, 22(4), p 452-462. https://doi.org/10.1007/s11666-013-9885-z

F. Ghadami, A.S.R. Aghdam and S. Ghadami, Isothermal and Cyclic Oxidation Behavior of HVOF-Sprayed NiCoCrAlY Coatings: Comparative Investigations on the Conventional and Nanostructured Coatings, J. Therm. Spray Technol., 2020, 29, p 1926-1942. https://doi.org/10.1007/s11666-020-01111-9

Z. Zhou, L. Wang, F.C. Wang, H.F. Zhang, Y.B. Liu and S.H. Xu, Formation and Corrosion Behavior of Fe-Based Amorphous Metallic Coatings by HVOF Thermal Spraying, Surf. Coat. Technol., 2009, 204(5), p 563-570. https://doi.org/10.1016/j.surfcoat.2009.08.025

Y. An, G. Hou, J. Chen, X. Zhao, G. Liu, H. Zhou and J. Chen, Microstructure and Tribological Properties of Iron-Based Metallic Glass Coatings Prepared by Atmospheric Plasma Spraying, Vacuum, 2014, 107, p 132-140. https://doi.org/10.1016/j.vacuum.2014.04.021

F. Ghadami, M.A. Davoudabadi and S. Ghadami, Cyclic Oxidation Properties of the Nanocrystalline AlCrFeCoNi High-Entropy Alloy Coatings Applied by the Atmospheric Plasma Spraying Technique, Coatings, 2022, 12(3), p 372. https://doi.org/10.3390/coatings12030372

S. Vignesh, K. Shanmugam, V. Balasubramanian, K. Sridhar and D. Thirumalaikumarasamy, Electrochemical Corrosion Behaviour of HVOF Sprayed Iron-Based Amorphous Metallic Coatings on AISI 316 Stainless Steel in an NaCl Solution, J. Mech. Behav. Mater., 2018, 27(3–4), p 1-9. https://doi.org/10.1515/jmbm-2018-0015

H. Guo, S. Zhang, W. Sun and J. Wang, Differences in Dry Sliding Wear Behavior between HVAF-Sprayed Amorphous Steel and Crystalline Stainless Steel Coatings, J. Mater. Sci. Technol., 2019, 35(5), p 865-874. https://doi.org/10.1016/j.jmst.2018.11.006

J. Henao, A. Concustell, I.G. Cano, N. Cinca, S. Dosta and J.M. Guilemany, Influence of Cold Gas Spray Process Conditions on the Microstructure of Fe-Based Amorphous Coatings, J. Alloys Compd., 2015, 622, p 995-999. https://doi.org/10.1016/j.jallcom.2014.11.037

H. Yuan, H. Zhai, W. Li, D. He, B. Cheng and L. Feng, Study of Dry Sliding Wear Behavior of a Fe-Based Amorphous Coating Synthesized by Detonation Spraying on an AZ31B Magnesium Alloy, J. Mater. Eng. Perform., 2021, 30(2), p 905-917. https://doi.org/10.1007/s11665-020-05357-w

J. Luo, N. Shi, Y.Z. Xing, C. Jiang and Y. Chen, Effect of Arc Power on the Wear and High-Temperature Oxidation Resistances of Plasma-Sprayed Fe-Based Amorphous Coatings, High Temp. Mater. Process., 2019, 38, p 639-646. https://doi.org/10.1515/htmp-2019-0003

A. Kumar, R. Kumar, P. Bijalwan, M. Dutta, A. Banerjee and T. Laha, Fe-Based Amorphous/Nanocrystalline Composite Coating by Plasma Spraying: Effect of Heat Input on Morphology, Phase Evolution and Mechanical Properties, J. Alloys Compd., 2019, 771, p 827-837. https://doi.org/10.1016/j.jallcom.2018.09.024

H.R. Ma, X.Y. Chen, J.W. Li, C.T. Chang, G. Wang, H. Li, X.M. Wang and R.W. Li, Fe-Based Amorphous Coating with High Corrosion and Wear Resistance, Surf. Eng., 2017, 33(1), p 56-62. https://doi.org/10.1080/02670844.2016.1176718

X. Li, H. Zhai, W. Li, S. Cui, W. Ning and X. Qiu, Dry Sliding Wear Behaviors of Fe-Based Amorphous Metallic Coating Synthesized by D-Gun Spray, J. Non Cryst. Solids, 2020, 537, p 120018. https://doi.org/10.1016/j.jnoncrysol.2020.120018

R.S. Maurya, A.S. Sahu and T. Laha, Quantitative phase Analysis in Al86Ni8Y6 Bulk Glassy Alloy Synthesized by Consolidating Mechanically Alloyed Amorphous Powder via Spark Plasma Sintering, Mater. Des., 2016, 93, p 96-103. https://doi.org/10.1016/j.matdes.2015.12.129

T. Gloriant, M. Gich, S. Suriñach, M.D. Baró and A.L. Greer, Evaluation of the Volume Fraction Crystallized during Devitrification of Al-Based Amorphous Alloys, Mater. Sci. Forum, 2000, 343, p 365-370. https://doi.org/10.4028/www.scientific.net/MSF.343-346.365

A. Kumar, S.K. Nayak, P. Bijalwan, M. Dutta, A. Banerjee and T. Laha, Optimization of Mechanical and Corrosion Properties of Plasma Sprayed Low-Chromium Containing Fe-Based Amorphous/Nanocrystalline Composite Coating, Surf. Coat. Technol., 2019, 370, p 255-268. https://doi.org/10.1016/j.surfcoat.2019.05.010

S.K. Nayak, A. Kumar, A. Pathak, A. Banerjee and T. Laha, Multi-Scale Mechanical Properties of Fe-Based Amorphous/Nanocrystalline Composite Coating Synthesized by HVOF Spraying, J. Alloys Compd., 2020, 825, p 154120. https://doi.org/10.1016/j.jallcom.2020.154120

G.Y. Koga, T. Ferreira, Y. Guo, D.D. Coimbrão, A.M. Jorge Jr., C.S. Kiminami, C. Bolfarini and W.J. Botta, Challenges in optimizing the resistance to corrosion and wear of amorphous Fe-Cr-Nb-B alloy containing crystalline phases, J. Non-Cryst. Solids, 2021, 555, p 120537. https://doi.org/10.1016/j.jnoncrysol.2020.120537

A. Agarwal and N. Dahotre, Nanoindentation, Mechanical Properties of Laser-Deposited Composite Boride Coating Using Nanoindentation, Metal. Mater. Trans. A, 2000, 31, p 401-408. https://doi.org/10.1007/s11661-000-0277-x

L. Xie, X. Xiong, Y. Zeng and Y. Wang, The Wear Properties and Mechanism of Detonation Sprayed Iron-Based Amorphous Coating, Surf. Coatings Technol., 2019, 366, p 146-155. https://doi.org/10.1016/j.surfcoat.2019.03.028

H. Zhang, Y. Xie, L. Huang, S. Huang, X. Zheng and G. Chen, Effect of Feedstock Particle Sizes on Wear Resistance of Plasma Sprayed Fe-Based Amorphous Coatings, Surf. Coatings Technol., 2014, 258, p 495-502. https://doi.org/10.1016/j.surfcoat.2019.03.028

Acknowledgments

The author, T. Laha thankfully acknowledges Science and Engineering Research Board, Department of Science and Technology, Govt. of India (CRG/2020/000738) and Defence Research and Development Organisation, Govt. of India (ERIP/ER/202101002/M/01/1783) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on New and Emerging Markets in Thermal Spray. The issue was organized by Dr. Andrew Vackel, Sandia National Laboratories; Dr. John Koppes, TST Engineered Coating Solutions; Prof. Bertrand Jodoin, University of Ottawa; Dr. Dheepa Srinivasan, Pratt and Whitney; and Prof. Shrikant Joshi, University West.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Faridi, M.A., Nayak, S.K., Prasad, D.K.V.D. et al. Effect of Microstructure and Phase Evolution on the Wear Behavior of Fe-Based Amorphous/Nanocrystalline Composite Coatings Synthesized by Plasma Spraying. J Therm Spray Tech 32, 2054–2067 (2023). https://doi.org/10.1007/s11666-023-01631-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01631-0