Abstract

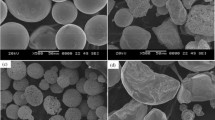

The Fe-based coatings in powder form were deposited on a steel type E335 by flame spraying technique. The effects of the post heat treatment on the microstructure and the mechanical properties of sprayed coatings were studied. Post heat treatment was conducted in a furnace in air at 623 K, 823 K and 1023 K for 1 h and then cooled in air. The results showed that with the increase of annealing temperature, the microstructure of coating treated at 823 K and 1023 K had several changes as follows: the reduction of porosity, formation of carbides and oxides. It was found that the solid solution FCC (Fe, Ni), intermetallic compound AlFe3 and carbides [Fe, C] were the main phases for coatings as-sprayed and treated at 623 K and while iron carbide, molybdenum carbide and oxide as Fe3O4 became the main phases and reinforced the solid solution FCC (Fe, Ni) phase for annealed coatings at 823 K. However, it was observed the disappearance of molybdenum carbide and oxide Fe3O4 at 1023 K. The coating annealed at 823 K exhibited an excellent wear resistance than the as-sprayed and annealed coatings at 623 K and 1023 K and shows the lower wear rate than another coating treated or as sprayed.

摘要

采用火焰喷涂技术在E335 钢上制备粉末状Fe 基涂层。研究了后续热处理对涂层组织和力学性 能的影响。在623 K、823 K 和1023 K 的空气中对涂层进行后续热处理1 h,然后随炉在空气中冷却。 结果表明,随着退火温度的升高,823 K 和1023 K 处理后涂层的微观结构发生了如下变化:孔隙率降 低,碳化物和氧化物形成。在623 K 时,涂层的主要相为固溶体FCC(Fe,Ni)、金属间化合物AlFe3 和碳化物[Fe,C];碳化铁、碳化钼和氧化铁Fe3O4 作为主要相增强了823 K 退火涂层中的固溶体 FCC(Fe,Ni)相;但在1023 K 处理涂层中观察到碳化钼和氧化物Fe3O4 消失了。823 K 退火涂层的耐 磨性优于623 K 和1023 K 退火涂层,其磨损率最低。

Similar content being viewed by others

References

Fuji M, Yoshida A, Mab J, Shigemurac S, Tanic K. Rolling contact fatigue of alumina ceramics sprayed on steel roller under pure rolling contact condition [J]. Tribological International, 2006, 39: 856–862. DOI: https://doi.org/10.1016/j.triboint.2005.07.038.

Ahmed R. Contact fatigue failure modes of HVOF coatings [J] Wear, 2002, 253: 473–487. DOI: https://doi.org/10.1016/S0043-1648(02)00163-1.

Gao Y, Xu X, Yan Z, Xin G. High hardness alumina coatings prepared by low Power plasma spraying [J]. Surf Coat Technol, 2002, 154: 189–193. DOI: https://doi.org/10.1016/S0257-8972(01)01711-X.

Nieminen R, Vuoristo P, Niemi K, Mantyla T, Barbezat G. Rolling contact fatigue failure mechanisms in plasma and HVOF sprayed WC-Co coatings [J]. Wear, 1997, 212: 66–77. DOI: https://doi.org/10.1016/S0043-1648(97)00138-5.

Stewart S, Ahmed R, Itsukaichi T. Contact fatigue failure evaluation of post-treated WC–NiCrBSi functionally graded thermal spray coatings [J]. Wear, 2004, 257: 962–983. DOI: https://doi.org/10.1016/j.wear.2004.05.008.

Nakajima A, Mawatari T, Yoshida M, Tani K, Nakahira A. Effects of coating thickness and slip ratio on durability of thermally sprayed WC cermet coating in rolling/sliding contact [J]. Wear, 2000, 241: 166–173. DOI: https://doi.org/10.1016/S0043-1648(00)00371-9.

Bradai M A, Sad-Eddine A, Mouadji Y, Benabbas A, Bounar N, Mammeri A. Microstructural and mechanical properties of Ni-base thermal spray coatings deposited by flame spraying [J]. Metall Mater Trans B, 2011, 42: 923–938.

Zhang Lei, Dong Xuan-Pu, Li Ji-Qiang, Li Kan, Zhang Zong-Kui, Wang Wen-Jun, Fan Zi-Tian. Microstructure evolution of Al-Si semi-solid slurry by gas bubble stirring method [J]. Journal of Central South University of Technology, 2011, 18: 1789–1794.

Peng Z, Shang Q, Zhang Z, Lu J. Microstructure and strengthening mechanism of Fe-based alloy powder cladding layer by plasma beam [J]. J Zhongyuan Univ Technol, 2007, 18(6): 6–9. (in Chinese)

Xia Peng-Cheng, Yu Jing-Jiang, Sun Xiao-Feng, Guan Heng-Rong, Hu Zhuang-qi. Influence of heat treatment on the microstructure and mechanical properties of DZ951 alloy [J]. Rare Met, 2008, 27 (2): 216–221.

Li H, Zhao G, He L. Finite element method based simulation of stress-strain field in the quenching process [J]. Mater Sci Eng A, 2008, 478: 276–290. DOI: https://doi.org/10.1016/j.msea.2007.05.101.

Chatterjee S, Shariff S M, Padmanabham G, Majumdar J D, Choudhury R A. Study on the effect of laser post-treatment on the properties of nano structured Al2O3–TiB2–TiN based coatings developed by combined SHS and laser surface alloying [J]. Surf Coat Technol, 2010, 205(1): 131–138. DOI: https://doi.org/10.1016/j.surfcoat. 2010.06.015.

Haque M M, Maleque M A. Effect of process variables on structure and properties of aluminium–silicon piston alloy [J]. J Mater Process Technol, 1998, 77(1–3): 122–128. DOI: https://doi.org/10.1016/S0924-0136(97)00409-3.

Zabihi F, Xie Y, Gao S, Eslamian M. Morphology, conductivity, and wetting characteristics of PEDOT:PSS thin films deposited by spin and spray coating, alloy [J]. App Surf Sci, 2015, 338: 163–177. DOI: https://doi.org/10.1016/j.apsusc.2015.02.128.

Choi S, Cho S, Lee J, Jeong D Y, Kim H. Reaction and interfacial structures between Ag paste with tellurite glass frits and Si wafer for solar cells [J]. Met Mater Inter, 2015, 21: 686–691.

Garcia C, Zhukov A, Gonzalez J, Zhukova V, Vargad R, Del Val J J, Larin V, Blanco J M. Studies of structural and magnetic properties of glass-coated nanocrystalline Fe79Hf7B12Si2 microwires [J]. J Alloy Compd, 2006, 423: 116–119. DOI: https://doi.org/10.1016/j.jallcom. 2005.12.029.

Park S Y, Kim M C, Park C G. Mechanical properties and microstructure evolution of the nano WC–Co coatings fabricated by detonation gun spraying with post heat treatment [J]. Mater Sci Eng A, 2007, 450: 894–897. DOI: https://doi.org/10.1016/j.msea.2006.02.444.

Bolleli G, Lusvarghi L. Heat treatment effects on the tribological performance of HVOF sprayed Co-Mo-Cr-Si coatings [J]. J Therm Spray Technol, 2006, 15(4): 802–810.

Bolelli G, Lusvarghi L, Barletta M. HVOFsprayed WC–CoCr coatings on Al alloy: Effect of the coating thickness on the tribological properties [J]. Wear, 2009, 267(5–8): 944–953. DOI: https://doi.org/10.1016/j.wear. 2008.12.066.

Ferguson J B, Schultz B F, Venugopalan D, Lopez H F, Rohatgi P K. On the superposition of strengthening mechanisms in dispersion strengthened alloys and metal-matrix nanocomposites: Considerations of stress and energy [J]. Met Mater Inter, 2014, 20(2): 375–388.

Yoo Y H, Lee S H, Kim J G, Kim J S, Lee C. Effect of heat treatment on the corrosion resistance of Ni-based and Cu-based amorphous alloy coatings [J]. J Alloy Compd, 2008, 461(1, 2): 304–311. DOI: https://doi.org/10.1016/j.jallcom.2007.06.118.

Zhang S L, Sun X J, Dong H. Effect of deformation on the evolution of spheroidization for the ultra high carbon steel [J]. Mater Sci Eng A, 2007, 457: 319–324. DOI: https://doi.org/10.1016/j.msea.2006.06.057.

Younes R, Bradai M A, Sad-Eddine A, Mouadji Y, Bilek A, Benabbas. Microstructural and tribological properties of Al2O3-13pctTiO2 thermal spray coatings deposited by flame spraying [J]. Metal Mater Trans B, 2015, 46(5): 2394–2403.

Cho T Y, Yoon J H, Kim S, Song K O, Joo Y K, Fang W, Zhang S H,Youn S J, Chun H G, Hwang S Y. A study on HVOF coatings of micron and nano WC–Co powders [J]. Surf Coat Technol, 2009, 203: 5556–5559. DOI: https://doi.org/10.1016/j.surfcoat.2008.06.106.

Tian W, Wang Y, Yang Y. Fretting wear behavior of conventional and nanostructured Al2O3–13 wt%TiO2 coatings fabricated by plasma spray [J]. Wear, 2008 265: 1700–1707. DOI: https://doi.org/10.1016/j.wear.2008.04. 012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mouadji, Y., Bradai, M.A., Younes, R. et al. Influence of heat treatment on microstructure and tribological properties of flame spraying Fe-Ni-Al alloy coating. J. Cent. South Univ. 25, 473–481 (2018). https://doi.org/10.1007/s11771-018-3751-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3751-6