Abstract

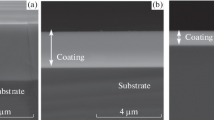

Ti-Si-N composite coatings were synthesized on a novel combining cathode and middle-frequency magnetron sputtering system, designed on an industrial scale. Ti was produced from the arc target and Si from magnetron target during deposition. The influences of negative bias voltage and Si content on the hardness and microstructure of the coatings were investigated. The composite coatings prepared under optimized conditions were characterized to be nc-TiN/a-Si3N4 structure with grain sizes of TiN ranging from 8–15 nm and exhibited a high hardness of 40 GPa. The enhancement of the hardness is suggested to be caused by the nanograin-amorphous structure effects.

Similar content being viewed by others

References

Mayrhofer P H, Mitterer C, Hultman L, et al. Microstructural Design of Hard Coatings[J]. Prog. Mater. Sci., 2006, 51: 1032–1114

Hutchings I M Tribology. Friction and Wear of Engineering Materials[M]. Edward Arnold, London, 1992

Veprek S, Reiprich S, Li S Z. Superhard Nanocrystalline Composite Materials: the TiN/Si3N4 System[J]. Appl. Phys. Lett., 1995, 66: 2640–2642

Diserens M, Patscheider J, Levy F. Improving the Properties of Titanium Nitride by Incorporation of Silicon[J]. Surf. Coat. Technol., 1998, 108–109: 241–246

Zhang C H, Lu X C, Wang H, et al. Microstructure, Mechanical Properties, and Oxidation Resistance of Nanocomposite Ti-Si-N Coatings[J]. Appl. Surf. Sci., 2006, 252: 6141–6153

Ma D Y, Ma S L, Xu K W. The Tribological and Structural Characterization of Nano-structured Ti-Si-N Films Coated by Pulsed-dc Plasma Enhanced CVD[J]. Vacuum, 2005, 79: 7–15

Rebouta L, Tavares C J, Aimo R, et al. Hard Nanocomposite Ti-Si-N Coatings Prepared by DC Reactive Magnetron Sputtering[J]. Surf. Coat. Technol., 2000, 133–134: 234–239

Watanabe H, Sato Y, Nie C Y, et al. Improving the Properties of Titanium Nitride by Incorporation of Silicon the Mechanical Properties and Microstructure of Ti-Si-N Nanocomposite Films by Ion Plating[J]. Surf. Coat. Technol., 2003, 169–170: 452–455

Jiang N, Shen Y G, Mai Y W, et al. Nanocomposite Ti-Si-N Films Deposited by Reactive Unbalanced Magnetron Sputtering at Room Temperature[J]. Mater. Sci. Eng. B, 2004, 106: 163–171

Varesi E, Pavia G, Zenkevich A, et al. Structural and Physical Analysis on MOCVD Ti-Si-N Films[J]. J. Phys. Chem. Solids, 2007, 68: 1046–1051

Heister U, Krempel-Hesse J, Szczyrbowskiet J, et al. TwinMag II: Improving an Advanced Sputtering Tool[J]. Vacuum, 2000, 59: 424–430

Rogozin A, Vinnichenko M, Shevchenko N, et al. Plasma Influence on the Properties and Structure of Indium Tin Oxide Films Produced by Reactive Middle Frequency Pulsed Magnetron Sputtering[J]. Thin Solid Films, 2006, 496: 197–204

Yang B, Huang Z H, Liu C S, et al. Characterization and Properties of Ti-containing Amorphous Carbon Nanocomposite Coatings Prepared by Middle Frequency Magnetron Sputtering[J]. Surf. Coat. Technol., 2006, 200: 5812–5818

Bai X M, Zheng W T, An Tao. Superhard Nano-multilayers and Nanocomposite Coatings[J]. Prog. Nat. Sci., 2005, 15: 97–107

Choi S R, Park I W, Park J H, et al. Influence of Substrate Bias Voltage on Deposition Behavior and Microindentation Hardness of Ti-Si-N Coatings by a Hybrid Coating System of Arc Ion Plating and Sputtering Techniques[J]. Surf. Coat. Technol., 2004, 179: 89–94

Choi S R, Park I W, Kimb S H, et al. Effects of Bias Voltage and Temperature on Mechanical Properties of Ti-Si-N Coatings Deposited by a Hybrid System of Arc Ion Plating and Sputtering Techniques[J]. Thin Solid Films, 2004, 447–448: 371–376

Petch N J. The Cleavage Strength of Polycrystals[J]. J. Iron Steel Inst., 1953, 174: 25–28

Zhao H Y, Fan Q L, Song L X, et al. Synthesis and Characterization of Superhard Ti-Si-N Films Obtained in an Inductively Coupled Plasma Enhanced Chemical Vapor Deposition (ICP-CVD) with Magnetic Confinement[J]. Appl. Surf. Sci., 2006, 252: 3065–3072

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Natural Science Foundation of China(No.10435060 and No. 10675095)

Rights and permissions

About this article

Cite this article

Yang, Z., Zhu, L., Yang, B. et al. Structure and properties of Ti-Si-N coatings synthesized by combining cathode arc and middle-frequency magnetron sputtering. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 24, 702–705 (2009). https://doi.org/10.1007/s11595-009-5702-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-009-5702-4