Abstract

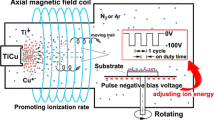

The huge potential of High-power impulse magnetron sputtering (HIPIMS) to improve the properties of deposited coatings has been verified. In this study, Ti-Si-N coatings were deposited on Si (111), glass and cemented carbide substrates by using HIPIMS. The influences of the peak voltage, duty cycle and total gas pressure on the transient peak current of the Ti90Si10 target was investigated in detailed. The (200) diffraction intensity decreased with increasing bias voltage from -50 V to -400 V. The hardness of the Ti-Si-N coatings deposited at various bias voltages and the internal stress at different bias voltages were studied. The results indicate that HIPIMS technology can considerably improve the mechanical capacity of the Ti-Si-N coatings, possibly due to the combined protection of the increased adhesive force with the substrate and the relatively high hardness, which are caused by densification and dislocation strengthening effects.

Similar content being viewed by others

References

P. H. Mayrhofer, F. Kunc, J. Musil and C. Mitterer, Thin Solid Films 415, 151 (2002).

S. Adhikari, A. M. M. Omer, S. Adhikary, M. Rusop, H. Uchida and M. Umeno, Diamond Relat. Mater. 15, 913 (2006).

U. Helmersson, M. Lattemann, J. Bohlmark, A. P. Ehiasarian and J. T. Gudmundsson, Thin Solid Films 513, 1 (2006).

A. P. Ehiasarian, W. D. Münz, L. Hultman, U. Helmersson and I. Petrov, Surf. Coat. Technol. 163, 267 (2003).

J. Bohlmark, M. Lattemann, J. T. Gudmundsson, A. P. Ehiasarian, Y. Aranda Gonzalvo, N. Brenning and U. Helmersson, Thin Solid Films 515, 1522 (2006).

K. Sarakinos, J. Alami and S. Konstantinidis, Surf. Coat. Technol. 204, 1661 (2010).

M. Aiempanakit, T. Kubart, P. Larsson, K. Sarakinos, J. Jensen and U. Helmersson, Thin Solid Films 519, 7779 (2011).

A. P. Ehiasarian, Research Signpost, edited by R. Wei (Trivandrum, India, 2008), p. 86.

W. D. Münz, A. P. Ehiasarian and P. Eh. Hovsepian, EP20020011204, 21 May 2001.

K. Gołombeka, L. A. Dobrzanskia and M. Sokovi, J. Mater. Process. Technol. 157, 341 (2004).

H. Watanabe, Y. Sato, C. Y. Nie, A. Ando, S. Ohtani and N. Iwamoto, Surf. Coat. Technol. 169, 452 (2003).

A. Yazdani, M. Soltanieh, H. Aghajani and S. Rastegari, Vacuum 86, 131 (2011).

S. Veprek, R. F. Zhang, M. G. J. Veprek-Heijman, S. H. Sheng and A. S. Argon, Surf. Coat. Technol. 204, 1898 (2010).

A. Bubenzer, B. Dischler, G. Brandt and P. Koidl, J. Appl. Phys. 54, 4590 (1983).

X. F Tang, F. Luo and F. Ou, Appl. Surf. Sci. 259, 448 (2012).

Y. J. Zhang, Y. Z. Yang and Y. H. Zhai, Appl. Surf. Sci. 258, 6897 (2012).

V. N. Zhitormirsky, L. Rapoport and R. L. Boxman, Surf. Coat. Technol. 133, 114 (2000).

S. H. Kim, J. K. Kim and K. H. Kim, Thin Solid Films 420, 360 (2002).

Z. Y. Wang, X. Sheng and X. C. Liu, Acta. Metall. Sin. 5, 540 (2014).

J. Pelleg, L. Z. Zevin, S. Lungo and N. Croitoru, Thin Solid Films 197, 117 (1991).

Z. T. Yang, B. Yang, L. P. Guo and D. J. Fu, J. Appl. Phys. 473, 437 (2009).

J. F. Moulder, W. F. Sticke, P. E. Sobol and K. D. Bomben, Handbook of X-Ray Photoelectron Spectroscopy (Perkin-Elmer Corporation Eden Prairie, 1992).

C. A. Davis, Thin Solid Films 226, 1692 (1993).

M. Lattermann, U. Helmersson and J. E. Greene, Thin Solid Films 518, 5978 (2010).

Y. P. Sharkeev, B. P. Gritsenko, S. V. Fortuna and A. J Perry, Vacuum 52, 247 (1999).

J. M. Poitevin, G. Lemperiere and J. Tardy, Thin Solid Films 97, 69 (1982).

Q. H. Kong, Li Ji, H. X. Li, X. H. Liu and H. D. Zhou, Mater. Sci. Eng. B 176, 850 (2011).

J. W. Lee, S. K. Tien and Y. C. Kuo, Thin Solid Films 494, 161 (2006).

S. Hao, S. B. Delley, S. Veprek and C. Stampfl, Phys. Rev. Lett. 97, 086102 (2006).

S. Hao, B. Delley and C. Stampfl, Phys. Rev. B 74, 035402 (2006).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ding, J., Zou, C., Wang, Q. et al. Effect of bias voltage on the microstructure and hardness of Ti-Si-N films deposited by using high-power impulse magnetron sputtering. Journal of the Korean Physical Society 68, 351–356 (2016). https://doi.org/10.3938/jkps.68.351

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.68.351