Abstract

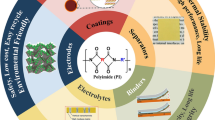

Polyimide (PI) is a kind of favorite polymer for the production of the membrane due to its excellent physical and chemical properties, including thermal stability, chemical resistance, insulation, and self-extinguishing performance. We review the research progress of PI separators in the field of energy storage—the lithium-ion batteries (LIBs), focusing on PI separators containing different groups and compounding with different substances. This review will help to optimize the PI separator material for the LIBs and favor understanding the preparation-groups, structure-performance relationship of porous separators in LIBs. Therefore, the advantages of PI separators in lithium-ion batteries are introduced in detail and the development of PI separators to the lithium-ion batteries is prospected.

Similar content being viewed by others

References

Jin Y, Zhu B, Lu Z et al (2017) Challenges and recent progress in the development of Si anodes for lithium-ion battery. Adv Energy Mater 7(23):1700715.1–1700715.17

Goodenough JB, Park K-S (2013) The Li-ion rechargeable battery: a perspective. J Am Chem Soc 135(4):1167–1176

Zhao C, Lu Y, Chen L et al (2019) Flexible Na batteries. InfoMat 2(1):126–138

Scrosati B, Garche J (2010) Lithium batteries: status, prospects and future. J Power Sources 195(9):2419–2430

Nunes-Pereira J, Lopes AC, Costa CM, Rodrigues LC, Silva MM, Lanceros-Méndez S (2013) Microporous membranes of NaY zeolite/poly(vinylidene fluoride–trifluoroethylene) for Li-ion battery separators. J Electroanal Chem 689(2):223–232

Manthiram A, Chung SH, Zu C (2015) Lithium–sulfur batteries: progress and prospects. Adv Mater 27(12):1980–2006

Cai Y, Cao X, Luo Z, Fang G, Liu F, Zhou J, Pan A, Liang S (2018) Caging Na3V2(PO4)2F3 microcubes in cross-linked graphene enabling ultrafast sodium storage and long-term cycling. Adv Sci (Weinh) 5(9):1800680

Zhang Y, Song YZ, Yuan JJ, Yin X, Sun CC, Zhu BK (2018) Polypropylene separator coated with a thin layer of poly (lithium acrylate-co-butyl acrylate) for high-performance lithium-ion batteries. J Appl Polym Sci 135(26):46423

Liao H, Zhang H, Hong H, Li Z, Qin G, Zhu H, Lin Y (2016) Novel cellulose aerogel coated on polypropylene separators as gel polymer electrolyte with high ionic conductivity for lithium-ion batteries. J Membr Sci 514:332–339

Costa C, Leones R, Silva MM et al (2014) Influence of different salts in poly (vinylidene fluoride-co-trifluoroethylene) electrolyte separator membranes for battery applications. J Electroanal Chem 727:125–134

Zhang J, Liu Z, Kong Q, Zhang C, Pang S, Yue L, Wang X, Yao J, Cui G (2013) Renewable and superior thermal-resistant cellulose-based composite nonwoven as lithium-ion battery separator. ACS Appl Mater Interfaces 5(1):128–134

Yuriar-Arredondo K, Armstrong MR, Shan B, Zeng W, Xu W, Jiang H, Mu B (2018) Nanofiber-based Matrimid organogel membranes for battery separator. J Membr Sci 546:158–164

Zhang J, Xiang Y, Jamil MI, Lu J, Zhang Q, Zhan X, Chen F (2018) Polymers/zeolite nanocomposite membranes with enhanced thermal and electrochemical performances for lithium-ion batteries. J Membr Sci 564:753–761

Qian J, Adams BD, Zheng J, Xu W, Henderson WA, Wang J, Bowden ME, Xu S, Hu J, Zhang JG (2016) Anode-free rechargeable lithium metal batteries. Adv Funct Mater 26(39):7094–7102

Lee H, Yanilmaz M, Toprakci O, Fu K, Zhang X (2014) A review of recent developments in membrane separators for rechargeable lithium-ion batteries. Energy Environ Sci 7(12):3857–3886

Shi C, Zhang P, Huang S, He X, Yang P, Wu D, Sun D, Zhao J (2015) Functional separator consisted of polyimide nonwoven fabrics and polyethylene coating layer for lithium-ion batteries. J Power Sources 298:158–165

Chen W, Liu Y, Ying M et al (2015) Improved performance of lithium ion battery separator enabled by co-electrospinnig polyimide/poly(vinylidene fluoride-co-hexafluoropropylene) and the incorporation of TiO2 -(2-hydroxyethyl methacrylate). J Power Sources 273:1127–1135

Li Y-H, Wu X-L, Kim J-H, Xin S, Su J, Yan Y, Lee JS, Guo YG (2013) A novel polymer electrolyte with improved high-temperature-tolerance up to 170 C for high-temperature lithium-ion batteries. J Power Sources 244:234–239

Wang Q, Song W-L, Wang L, Song Y, Shi Q, Fan LZ (2014) Electrospun polyimide-based fiber membranes as polymer electrolytes for lithium-ion batteries. Electrochim Acta 132:538–544

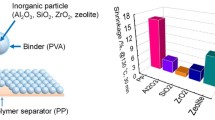

Shi C, Dai J, Xiu S et al (2016) A high-temperature stable ceramic-coated separator prepared with polyimide binder/Al2 O3 particles for lithium-ion batteries. J Membr Sci 517:91–99

Wang H, Wu J, Cai C, Guo J, Fan H, Zhu C, Dong H, Zhao N, Xu J (2014) Mussel inspired modification of polypropylene separators by catechol/polyamine for Li-ion batteries. ACS Appl Mater Interfaces 6(8):5602–5608

Myung-Hyun R, Min LY, Jung-Ki P et al (2011) Mussel-inspired polydopamine-treated polyethylene separators for high-power li-ion batteries. Adv Mater 23(27):3066–3070

Pan L, Wang H, Wu C, Liao C, Li L (2015) Tannic-acid-coated polypropylene membrane as a separator for lithium-ion batteries. ACS Appl Mater Interfaces 7(29):16003–16010

Lee J, Lee C-L, Park K, Kim ID (2014) Synthesis of an Al2O3-coated polyimide nanofiber mat and its electrochemical characteristics as a separator for lithium ion batteries. J Power Sources 248:1211–1217

Miao Y-E, Zhu G-N, Hou H, Xia YY, Liu T (2013) Electrospun polyimide nanofiber-based nonwoven separators for lithium-ion batteries. J Power Sources 226:82–86

Yan X, Wang Y, Tao Y et al (2016) Polyimide binder by combining with polyimide separator for enhancing the electrochemical performance of lithium ion batteries. Electrochim Acta 216:1–7

Smith SA, Williams BP, Joo YL (2017) Effect of polymer and ceramic morphology on the material and electrochemical properties of electrospun PAN/polymer derived ceramic composite nanofiber membranes for lithium ion battery separators. J Membr Sci 526:315–322

Li H, Wu D, Wu J, Dong LY, Zhu YJ, Hu X (2017) Flexible, high-wettability and fire-resistant separators based on hydroxyapatite nanowires for advanced lithium-ion batteries. Adv Mater 29(44):1703548

Hu F, Song T (2017) Application of functionalized ether in lithium ion batteries. RSC Adv 7(85):54203–54212

Chen X, Wang Z, Xu H, Zhou H, Zhou M, Li Y (2020) Study on molding process of ether anhydride type polyimide materials. IOP Conference Series: Materials Science and Engineering 772:012037

Cao L, Ping A, Xu Z et al (2016) Performance evaluation of electrospun polyimide non-woven separators for high power lithium-ion batteries. J Electroanal Chem 767:34–39

Zhang H, Lin CE, Zhou MY, John AE, Zhu BK (2016) High thermal resistance polyimide separators prepared via soluble precusor and non-solvent induced phase separation process for lithium ion batteries. Electrochim Acta 187:125–133

Zou X, Lu Q, Zhong Y, Liao K, Zhou W, Shao Z (2018) Flexible, flame-resistant, and dendrite-impermeable gel-polymer electrolyte for Li–O2/air batteries workable under hurdle conditions. Small 14(34):1801798

Zhao C-Z, Zhang X-Q, Cheng X-B, Zhang R, Xu R, Chen PY, Peng HJ, Huang JQ, Zhang Q (2017) An anion-immobilized composite electrolyte for dendrite-free lithium metal anodes. Proc Natl Acad Sci 114(42):11069–11074

Li D, Zhang H, Li X (2018) Porous polyetherimide membranes with tunable morphology for lithium-ion battery. J Membr Sci 565:42–49

Xu H, Li M, Han K, Xiao J, Chen X, Li Y (2019) Study on preparation and properties of polyimide lithium battery separator. IOP Conference Series: Materials Science and Engineering 493:012080

Jeong H-S, Kim D-W, Jeong YU, Lee SY (2010) Effect of phase inversion on microporous structure development of Al2O3/poly(vinylidene fluoride-hexafluoropropylene)-based ceramic composite separators for lithium-ion batteries. J Power Sources 195(18):6116–6121

Li M, Zhang Z, Yin Y, Guo W, Bai Y, Zhang F, Zhao B, Shen F, Han X (2020) Novel polyimide separator prepared with two porogens for safe lithium-ion batteries. ACS Appl Mater Interfaces 12(3):3610–3616

Jiang W, Liu Z, Kong Q, Yao J, Zhang C, Han P, Cui G (2013) A high temperature operating nanofibrous polyimide separator in Li-ion battery. Solid State Ionics 232:44–48

Zhai L, Yang S, Fan L (2012) Preparation and characterization of highly transparent and colorless semi-aromatic polyimide films derived from alicyclic dianhydride and aromatic diamines. Polymer 53(16):3529–3539

Liaw D-J, Wang K-L, Huang Y-C, Lee KR, Lai JY, Ha CS (2012) Advanced polyimide materials: syntheses, physical properties and applications. Prog Polym Sci 37(7):907–974

Kong L, Yan Y, Qiu Z, Zhou Z, Hu J (2018) Robust fluorinated polyimide nanofibers membrane for high-performance lithium-ion batteries. J Membr Sci 549:321–331

Qiu Z, Wang J, Zhang Q, Zhang S, Ding M, Gao L (2006) Synthesis and properties of soluble polyimides based on isomeric ditrifluoromethyl substituted 1, 4-bis (4-aminophenoxy) benzene. Polymer 47(26):8444–8452

Wang H, Wang T, Yang S, Fan L (2013) Preparation of thermal stable porous polyimide membranes by phase inversion process for lithium-ion battery. Polymer 54(23):6339–6348

Tan J, Kong L, Qiu Z et al (2018) Flexible, high-wettability and thermostable separator based on fluorinated polyimide for lithium-ion battery. J Solid State Electrochem 22(8):1–11

Zha J-W, Jia H-J, Wang H-Y, Dang ZM (2012) Tailored ultralow dielectric permittivity in high-performance fluorinated polyimide films by adjusting nanoporous characterisitics. J Phys Chem C 116(44):23676–23681

Fei S, Wang T, Yang S et al (2010) Synthesis and characterization of sulfonated polyimides bearing sulfonated aromatic pendant group for DMFC applications. Polymer 51(17):3887–3898

Kim M, Park JH (2012) Inorganic thin layer coated porous separator with high thermal stability for safety reinforced Li-ion battery. J Power Sources 212:22–27

Liu H, Dai Z, Xu J, Guo B, He X (2014) Effect of silica nanoparticles/poly (vinylidene fluoride-hexafluoropropylene) coated layers on the performance of polypropylene separator for lithium-ion batteries. Journal of Energy Chemistry 23(5):582–586

Zhang Z, Yuan W, Li L (2018) Enhanced wettability and thermal stability of nano-SiO2/poly (vinyl alcohol)-coated polypropylene composite separators for lithium-ion batteries. Particuology 37:91–98

Shekarian E, Jafari Nasr MR, Mohammadi T, Bakhtiari O, Javanbakht M (2019) Preparation of 4A zeolite coated polypropylene membrane for lithium-ion batteries separator. J Appl Polym Sci 136(32):47841

Li H, Lin F, Wang H, Wu H, Yang Y, Yu L, Liu W, Luo D (2020) Enhanced thermal stability and wettability of an electrospun fluorinated poly(aryl ether ketone) fibrous separator for lithium-ion batteries. New J Chem 44(10):3838–3846

Costa CM, Silva MM, Lanceros-Méndez S (2013) Battery separators based on vinylidene fluoride (VDF) polymers and copolymers for lithium ion battery applications. RSC Adv 3(29):11404–11417

Li J, Bi S, Li M, Xian Y, Shui Y, Yao Y, Wu M (2020) Rapid homogenization preparation of the mussel-inspired hydrophilic separator for high power lithium-ion batteries. J Appl Polym Sci 137:49052

Zhu YS, Xiao SY, Li MX, Chang Z, Wang FX, Gao J, Wu YP (2015) Natural macromolecule based carboxymethyl cellulose as a gel polymer electrolyte with adjustable porosity for lithium ion batteries. J Power Sources 288:368–375

Komaba S, Okushi K, Ozeki T, Yui H, Katayama Y, Miura T, Saito T, Groult H (2009) Polyacrylate modifier for graphite anode of lithium-ion batteries. Electrochem Solid-State Lett 12(5):A107–A110

Lin C, Zhang H, Song YZ et al (2017) Carboxylated polyimide separator with excellent lithium ion transport properties for a high-power density lithium-ion battery. J Mater Chem A 6(3):991–998

Wang X, Liu Z, Kong Q, Jiang W, Yao J, Zhang C, Cui G (2014) A single-ion gel polymer electrolyte based on polymeric lithium tartaric acid borate and its superior battery performance. Solid State Ionics 262(1):747–753

Yang P, Zhang P, Shi C, Chen L, Dai J, Zhao J (2015) The functional separator coated with core–shell structured silica–poly (methyl methacrylate) sub-microspheres for lithium-ion batteries. J Membr Sci 474:148–155

Zhang P, Chen L, Shi C, Yang P, Zhao J (2015) Development and characterization of silica tube-coated separator for lithium ion batteries. J Power Sources 284:10–15

Shi C, Zhang P, Chen L, Yang P, Zhao J (2014) Effect of a thin ceramic-coating layer on thermal and electrochemical properties of polyethylene separator for lithium-ion batteries. J Power Sources 270:547–553

Cai Z, Liu Y, Liu S, Li L, Zhang Y (2012) High performance of lithium-ion polymer battery based on non-aqueous lithiated perfluorinated sulfonic ion-exchange membranes. Energy Environ Sci 5(2):5690–5693

Liang X, Yang Y, Jin X, Huang Z, Kang F (2015) The high performances of SiO2/Al2O3-coated electrospun polyimide fibrous separator for lithium-ion battery. J Membr Sci 493:1–7

Shin W-K, Kim D-W (2013) High performance ceramic-coated separators prepared with lithium ion-containing SiO2 particles for lithium-ion batteries. J Power Sources 226:54–60

Ying W, Wang S, Fang J et al (2017) A nano-silica modified polyimide nanofiber separator with enhanced thermal and wetting properties for high safety lithium-ion batteries. J Membr Sci 537:248–254

Sun G, Dong G, Kong L, Yan X, Tian G, Qi S, Wu D (2018) Robust polyimide nanofibrous membrane with porous-layer-coated morphology by in situ self-bonding and micro-crosslinking for lithium-ion battery separator. Nanoscale 10(47):22439–22447

Dong G, Liu B, Sun G, Tian G, Qi S, Wu D (2019) TiO2 nanoshell@polyimide nanofiber membrane prepared via a surface-alkaline-etching and in-situ complexation-hydrolysis strategy for advanced and safe LIB separator. J Membr Sci 577:249–257

Kong L, Wang Y, Yu H, Liu B, Qi S, Wu D, Zhong WH, Tian G, Wang J (2018) In situ armoring: a robust, high-wettability, and fire-resistant hybrid separator for advanced and safe batteries. ACS Appl Mater Interfaces 11(3):2978–2988

Dong G, Dong N, Liu B, Tian G, Qi S, Wu D (2020) Ultrathin inorganic-nanoshell encapsulation: TiO2 coated polyimide nanofiber membrane enabled by layer-by-layer deposition for advanced and safe high-power LIB separator. J Membr Sci 601:117884

Li Y, Wang X, Liang J, Wu K, Xu L, Wang J (2020) Design of a high performance zeolite/polyimide composite separator for lithium-ion batteries. Polymers 12(4):764

Wan Y, Jian Z, Liao X et al (2015) Hierarchical three-dimensional micro/nano-architecture of polyaniline nanowires wrapped-on polyimide nanofibers for high performance lithium-ion battery separators. J Power Sources 299(60):417–424

Park S, Son CW, Lee S, Kim DY, Park C, Eom KS, Fuller TF, Joh HI, Jo SM (2016) Multicore-shell nanofiber architecture of polyimide/polyvinylidene fluoride blend for thermal and long-term stability of lithium ion battery separator. Sci Rep 6(1):36977–36977

Sun G, Kong L, Liu B, Niu H, Zhang M, Tian G, Qi S, Wu D (2019) Ultrahigh-strength, nonflammable and high-wettability separators based on novel polyimide-core@ polybenzimidazole-sheath nanofibers for advanced and safe lithium-ion batteries. J Membr Sci 582:132–139

Xu K, Qin Y, Xu T, Xie X, Deng J, Qi J, Huang C (2019) Combining polymeric membranes with inorganic woven fabric: towards the continuous and affordable fabrication of a multifunctional separator for lithium-ion battery. J Membr Sci 592:117364

Liu Z, Wen J, Kong Q et al (2013) A core@sheath nanofibrous separator for lithium ion batteries obtained by coaxial electrospinning. Macromol Mater Eng 298(7):806–813

Lee JH, Manuel J, Choi H, Park WH, Ahn JH (2015) Partially oxidized polyacrylonitrile nanofibrous membrane as athermally stable separator for lithium ion batteries. Polymer 68:335–343

Lin D, Zhuo D, Liu Y, Cui Y (2016) All-integrated bifunctional separator for Li dendrite detection via novel solution synthesis of a thermostable polyimide separator. J Am Chem Soc 138(34):11044–11050

Huang X (2011) Separator technologies for lithium-ion batteries. J Solid State Electrochem 15(4):649–662

Li D, Shi D, Xia Y, Qiao L, Li X, Zhang H (2017) Superior thermally stable and nonflammable porous polybenzimidazole membrane with high wettability for high-power lithium-ion batteries. ACS Appl Mater Interfaces 9(10):8742–8750

Liang N, Fang J, Guo X (2017) A simple approach for preparation of porous polybenzimidazole membranes as a promising separator for lithium ion batteries. J Mater Chem A 5(29):15087–15095

Saba H, Ihtesham R, Darr JA (2007) Synthesis and characterization of grafted nanohydroxyapatites using functionalized surface agents. Langmuir the Acs Journal of Surfaces & Colloids 23(12):6671–6676

Jung HR, Ju DH, Lee WJ, Zhang X, Kotek R (2009) Electrospun hydrophilic fumed silica/polyacrylonitrile nanofiber-based composite electrolyte membranes. Electrochim Acta 54(13):3630–3637

Yanilmaz M, Chen C, Zhang X (2013) Fabrication and characterization of SiO2/PVDF composite nanofiber-coated pp nonwoven separators for lithium-ion batteries. Journal of Polymer Science Part B Polymer Physics 51(23):1719–1726

Cui WW, Tang DY, Gong ZL (2013) Electrospun poly(vinylidene fluoride)/poly(methyl methacrylate) grafted TiO2 composite nanofibrous membrane as polymer electrolyte for lithium-ion batteries. J Power Sources 223:206–213

Deka M, Kumar A (2011) Electrical and electrochemical studies of poly(vinylidene fluoride)–clay nanocomposite gel polymer electrolytes for Li-ion batteries. J Power Sources 196(3):1358–1364

Gao K, Hu X, Yi T et al (2007) PE-g-MMA polymer electrolyte membrane for lithium polymer battery. Electrochim Acta 52(2):443–449

Shi J, Hu H, Xia Y, Liu Y, Liu Z (2014) Polyimide matrix-enhanced cross-linked gel separator with three-dimensional heat-resistance skeleton for high-safety and high-power lithium ion batteries. J Mater Chem A 2(24):9134–9141

Zhang H, Zhang Y, Yao Z, John AE, Li Y, Li W, Zhu B (2016) Novel configuration of polyimide matrix-enhanced cross-linked gel separator for high performance lithium ion batteries. Electrochim Acta 204:176–182

Shi JL, Fang LF, Li H, Zhang H, Zhu BK, Zhu LP (2013) Improved thermal and electrochemical performances of PMMA modified PE separator skeleton prepared via dopamine-initiated ATRP for lithium ion batteries. J Membr Sci 437(12):160–168

Lee JR, Won JH, Kim JH, Kim KJ, Lee SY (2012) Evaporation-induced self-assembled silica colloidal particle-assisted nanoporous structural evolution of poly(ethylene terephthalate) nonwoven composite separators for high-safety/high-rate lithium-ion batteries. J Power Sources 216(11):42–47

Byun S, Lee SH, Song D, Ryou MH, Lee YM, Park WH (2019) A crosslinked nonwoven separator based on an organosoluble polyimide for high-performance lithium-ion batteries. J Ind Eng Chem 72:390–399

Gui X, Liu L, Gao S, Sun L, Xu K, Chen M (2019) A novel silsesquioxanes modified electrospun composite fibrous separator by in-situ crosslinking method for lithium-ion batteries. Mater Lett 242:66–70

Liang X, Yang Y, Jin X, Cheng J (2016) Polyethylene oxide-coated electrospun polyimide fibrous seperator for high-performance lithium-ion battery. J Mater Sci Technol 32(3):200–206

Kong L, Yuan L, Liu B, Tian G, Qi S, Wu D (2017) Crosslinked polyimide nanofiber membrane prepared via ammonia pretreatment and its application as a superior thermally stable separator for Li-ion batteries. J Electrochem Soc 164(6):A1328–A1332

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, H., Shi, Y., Yuan, B. et al. Recent developments of polyimide materials for lithium-ion battery separators. Ionics 27, 907–923 (2021). https://doi.org/10.1007/s11581-020-03865-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-020-03865-2