Abstract

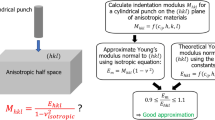

This study examined a method for approximating the transversely isotropic (TI) elastic mechanical properties and bedding plane orientations of randomly oriented rock cuttings. Microindentation testing was conducted on multiple rock cuttings with unknown bedding orientations to obtain their experimental indentation moduli. The measured indentation moduli were assumed to be functions of both the bedding orientations and the intrinsic TI mechanical properties of the rock cuttings. This assumption holds due to the anisotropic stress history and preferred horizontal alignment of the rock fabric along the bedding direction, as well as the presence of plate-like clay particles with intrinsic TI mechanical properties. An anisotropic contact mechanics solution was then utilized to predict both the TI elastic mechanical properties and bedding plane orientations of the cuttings using a constrained inverse algorithm that minimizes the error between the predicted indentation modulus (a function of both the predicted elastic constants and the orientation of the cuttings) and the experimental indentation modulus. Several constraints were imposed on the inverse algorithm to mathematically bound the TI stiffness matrix and optimization results. A Monte Carlo simulation was also incorporated into the inverse algorithm to consider the effects of uncertainties in the experimental results. The results obtained from the proposed indentation–inverse algorithm approach show good agreement with the results obtained using non-invasive ultrasonic pulse velocity measurements on a 2.5 cm cube sample.

Similar content being viewed by others

Notes

Buehler TexMet™ P is a registered trademark of Buehler, Lake Bluff, Illinois, USA.

Hysitron TI-950 Triboindenter® is a registered trademark of the Bruker Corporation, Billerica, Massachusetts USA.

References

Abedi S, Slim M, Hofmann R, Bryndzia T, Ulm FJ (2016) Nanochemo-mechanical signature of organic-rich shales: a coupled indentation-EDX analysis. Acta Geotech. https://doi.org/10.1007/s11440-015-0426-4

Abedi S, Slim M, Ulm F-J (2016) Nanomechanics of organic-rich shales: the role of thermal maturity and organic matter content on texture. Acta Geotech 11(4):775–787. https://doi.org/10.1007/s11440-016-0476-2

Araki H, Hasegawa S (2010) Micro-indentation tests to evaluate micro-scale mechanical properties of granites. Paper presented at the 44th U.S. rock mechanics symposium and 5th U.S.-Canada rock mechanics symposium, Salt Lake City, Utah, 1 Jan 2010

Argatov I, Mishuris G (2018) Indentation testing of biological materials. Springer, Cham. https://doi.org/10.1007/978-3-319-78533-2

Auvray C, Lafrance N, Bartier D (2017) Elastic modulus of claystone evaluated by nano-/micro-indentation tests and meso-compression tests. J Rock Mech Geotech Eng 9(1):84–91. https://doi.org/10.1016/j.jrmge.2016.02.002

Barber JR (1974) Determining the contact area in elastic-indentation problems. J Strain Anal Eng Des 9(4):230–232. https://doi.org/10.1243/03093247V094230

Barnett DM, Lothe J (1975) Dislocations and line charges in anisotropic piezoelectric insulators. Physica Status Solidi (B) 67(1):105–111. https://doi.org/10.1002/pssb.2220670108

Barry B, Klima MS (2013) Characterization of marcellus shale natural gas well drill cuttings. J Unconv Oil Gas Resour. https://doi.org/10.1016/j.juogr.2013.05.003

Boussinesq JV (1885) Application des Potentiels a l’Étude de l’Équilibre et du Mouvement des Solides Élastiques. Mémoires de la Societé des Sciences, de l’Agriculture et des Arts

Bulychev SI, Alekhin SI (1987) Method of kinetic hardness and microhardness in testing impression. Zavod Lab 53(11):1091–1096

Bulychev SI, Alekhin VP, Shorshorov MH, Ternovskii AP (1975) Determining Young’s modulus from the indentor penetration diagram. Zavod Lab 41:1409–1412

Bulychev SI, Alekhin VP, Shorshorov MK, Ternovskii AP (1976) Mechanical properties of materials studied from kinetic diagrams of load versus depth of impression during microimpression. Strength Mater 8(9):1084–1089. https://doi.org/10.1007/BF01529860

Canady W (2011) A method for full-range young’s modulus correction. Society of Petroleum Engineers—SPE Americas Unconventional Gas Conference 2011, UGC 2011

Chen JJ, Sorelli L, Vandamme M, Ulm F-J, Chanvillard G (2010) A coupled nanoindentation/SEM-EDS study on low water/cement ratio portland cement paste: evidence for C–S–H/Ca(OH)2 nanocomposites. J Am Ceram Soc 93(5):1484–1493. https://doi.org/10.1111/j.1551-2916.2009.03599.x

Chen P, Han Q, Ma T, Lin D (2015) The mechanical properties of shale based on micro-indentation test. Pet Explor Dev 42(5):723–732. https://doi.org/10.1016/S1876-3804(15)30069-0

Combal B, Baret F, Weiss M, Trubuil A, Macé D, Pragnère A, Myneni R, Knyazikhin Y, Wang L (2003) Retrieval of canopy biophysical variables from bidirectional reflectance: using prior information to solve the ill-posed inverse problem. Remote Sens Environ 84(1):1–15. https://doi.org/10.1016/S0034-4257(02)00035-4

Constantinides G, Ulm FJ, Van Vliet K (2003) On the use of nanoindentation for cementitious materials. Mater Struct 36(3):191–196. https://doi.org/10.1617/14020

D2845 A (2008) Standard test method for laboratory determination of pulse velocities and ultrasonic elastic constants of rock. https://doi.org/10.1520/d2845-08

Deirieh A, Ortega JA, Ulm FJ, Abousleiman Y (2012) Nanochemomechanical assessment of shale: a coupled WDS-indentation analysis. Acta Geotech 7(4):271–295. https://doi.org/10.1007/s11440-012-0185-4

Delafargue A, Ulm FJ (2004) Explicit approximations of the indentation modulus of elastically orthotropic solids for conical indenters. Int J Solids Struct 41(26):7351–7360. https://doi.org/10.1016/j.ijsolstr.2004.06.019

Delbos F, Gilbert JC, Glowinski R, Sinoquet D (2006) Constrained optimization in seismic reflection tomography: a Gauss–Newton augmented Lagrangian approach. Geophys J Int 164(3):670–684. https://doi.org/10.1111/j.1365-246X.2005.02729.x

Dewhurst DN, Sarout J, Delle Piane C, Siggins AF, Raven MD, Kuila U (2010) Prediction of shale mechanical properties from global and local empirical correlations. In: SEG technical program expanded abstracts 2010. Society of Exploration Geophysicists, pp 2595–2599. https://doi.org/10.1190/1.3513380

Doerner MF, Nix WD (1986) A method for interpreting the data from depth-sensing indentation instruments. J Mater Res 1(4):601–609. https://doi.org/10.1557/JMR.1986.0601

Dong G, Chen P (2017) A comparative experiment investigate of strength parameters for Longmaxi shale at the macro- and mesoscales. Int J Hydrog Energy 42(31):20082–20091. https://doi.org/10.1016/j.ijhydene.2017.05.240

Donnelly E, Baker SP, Boskey AL, Van Der Meulen MCH (2006) Effects of surface roughness and maximum load on the mechanical properties of cancellous bone measured by nanoindentation. J Biomed Mater Res Part A 77(2):426–435. https://doi.org/10.1002/jbm.a.30633

Egermann P, Lenormand R, Longeron D, Zarcone C (2005) A fast and direct method of permeability measurements on drill cuttings. SPE Reserv Eval Eng. https://doi.org/10.2118/77563-PA

Espinoza DN, Vandamme M, Dangla P, Pereira JM, Vidal-Gilbert S (2013) A transverse isotropic model for microporous solids: application to coal matrix adsorption and swelling. J Geophys Res Solid Earth 118(12):6113–6123. https://doi.org/10.1002/2013JB010337

Fan M, Jin Y, Chen M, Geng Z (2019) Mechanical characterization of shale through instrumented indentation test. J Pet Sci Eng 174:607–616. https://doi.org/10.1016/j.petrol.2018.11.083

Feng P, Dai F, Liu Y, Xu N, Fan P (2018) Effects of coupled static and dynamic strain rates on mechanical behaviors of rock-like specimens containing pre-existing fissures under uniaxial compression. Can Geotech J 55:640–652. https://doi.org/10.1139/cgj-2017-0286

Gautam R, Wong RC (2006) Transversely isotropic stiffness parameters and their measurement in Colorado shale. Can Geotech J 43:1290–1305. https://doi.org/10.1139/t06-083

Goktan RM, Gunes Yılmaz N (2017) Diamond tool specific wear rate assessment in granite machining by means of knoop micro-hardness and process parameters. Rock Mech Rock Eng 50(9):2327–2343. https://doi.org/10.1007/s00603-017-1240-0

Haber E, Horesh L, Tenorio L (2009) Numerical methods for the design of large-scale nonlinear discrete ill-posed inverse problems. Inverse Probl 26:025002. https://doi.org/10.1088/0266-5611/26/2/025002

Hadamard J (1923) Lectures on Cauch’s problem in linear partial differential equations. Yale University Press, New Haven

Hay JL, Pharr GM (2000) Instrumented indentation testing. ASM Int 8:232–243

Hertz H (1882) Ueber die Berührung fester elastischer Körper. Journal fur die Reine und Angewandte Mathematik 92:156–171. https://doi.org/10.1515/crll.1882.92.156

Homem-de-Mello T, Bayraksan G (2014) Monte Carlo sampling-based methods for stochastic optimization. Surv Oper Res Manag Sci 19(1):56–85. https://doi.org/10.1016/j.sorms.2014.05.001

Horsrud P (2001) Estimating mechanical properties of shale from empirical correlations. SPE Drill Complet. https://doi.org/10.2118/56017-pa

Howarth DF (1984) Apparatus to determine static and dynamic elastic moduli. Rock Mech Rock Eng 17:255–264. https://doi.org/10.1007/BF01032338

Ishida T, Labuz JF, Manthei G, Meredith PG, Nasseri MHB, Shin K, Yokoyama T, Zang A (2017) ISRM suggested method for laboratory acoustic emission monitoring. Rock Mech Rock Eng 50(3):665–674. https://doi.org/10.1007/s00603-016-1165-z

Jäger A, Bader T, De Borst K, Eberhardsteiner J (2011) The relation between indentation modulus, microfibril angle, and elastic properties of wood cell walls. Compos A Appl Sci Manuf 42:677–685. https://doi.org/10.1016/j.compositesa.2011.02.007

Jäger A, Hofstetter K, Buksnowitz C, Gindl-Altmutter W, Konnerth J (2011) Identification of stiffness tensor components of wood cell walls by means of nanoindentation. Compos A Appl Sci Manuf 42(12):2101–2109. https://doi.org/10.1016/j.compositesa.2011.09.020

Jakobsen M, Johansen TA (2000) Anisotropic approximations for mudrocks: a seismic laboratory study. Geophysics 65(6):1711–1725. https://doi.org/10.1190/1.1444856

Johnston JE, Christensen NI (1995) Seismic anisotropy of shales. J Geophys Res 100(B4):5991–6003. https://doi.org/10.1029/95JB00031

Kabanikhin S (2008) Definitions and examples of inverse and ill-posed problems. J Inverse Ill-Posed Probl 16(4):317–357. https://doi.org/10.1515/JIIP.2008.019

Li J, Yang S, Guo B, Feng Y, Liu G (2013) Distribution of the sizes of rock cuttings in gas drilling at various depths. CMES Comput Model Eng Sci. https://doi.org/10.3970/cmes.2012.089.079

Li J, Guo B, Yang S, Liu G (2014) The complexity of thermal effect on rock failure in gas-drilling shale-gas wells. J Nat Gas Sci Eng. https://doi.org/10.1016/j.jngse.2014.08.011

Lu Y, Li Y, Wu Y, Luo S, Jin Y, Zhang G (2020) Characterization of shale softening by large volume-based nanoindentation. Rock Mech Rock Eng 53(3):1393–1409. https://doi.org/10.1007/s00603-019-01981-8

Martogi D, Abedi S (2019) Indentation based method to determine the mechanical properties of randomly oriented rock cuttings. Paper presented at the 53rd U.S. rock mechanics/geomechanics symposium, New York City, New York, 28 Aug 2019

Martogi D, Abedi S, Saadeh C, Mitchell I (2019) Mechanical properties of drill cuttings based on indentation testing and contact mechanics solutions. Paper presented at the SPE annual technical conference and exhibition, Calgary, Alberta, Canada, 23 Sep 2019

Mashhadian M, Abedi S, Noshadravan A (2018) Probabilistic multiscale characterization and modeling of organic-rich shale poroelastic properties. Acta Geotech. https://doi.org/10.1007/s11440-018-0652-7

Meyers AG, Hunt SP, Behr S, Frick R (2005) Point load testing of drill cuttings for the determination of rock strength. Paper presented at the Alaska Rocks 2005, The 40th U.S. symposium on rock mechanics (USRMS), Anchorage, Alaska, 1 Jan 2005

Mirotchnik K, Kryuchkov S, Strack K (2018) A novel method to determine NMR petrophysical parameters from drill cuttings. In: SPWLA 45th annual logging symposium 2004

Monfared S, Laubie H, Radjai F, Hubler M, Pellenq R, Ulm F-J (2018) A methodology to calibrate and to validate effective solid potentials of heterogeneous porous media from computed tomography scans and laboratory-measured nanoindentation data. Acta Geotech 13(6):1369–1394. https://doi.org/10.1007/s11440-018-0687-9

Mosegaard K, Tarantola A (1995) Monte Carlo sampling of solutions to inverse problems. J Geophys Res Solid Earth 100(B7):12431–12447. https://doi.org/10.1029/94jb03097

Nejati M, Dambly MLT, Saar MO (2019) A methodology to determine the elastic properties of anisotropic rocks from a single uniaxial compression test. J Rock Mech Geotech Eng 11(6):1166–1183. https://doi.org/10.1016/j.jrmge.2019.04.004

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus (Young’s modulus). J Mater Res 7(6):1564–1583

Ortega JA (2010) Microporomechanical modeling of shale. In: Ph.D. Dissertation, Massachusetts Institute of Technology, Cambridge

Ortega JA, Ulm F-J, Abousleiman Y (2007) The effect of the nanogranular nature of shale on their poroelastic behavior. Acta Geotech 2(3):155–182. https://doi.org/10.1007/s11440-007-0038-8

Pereyra M, Schniter P, Chouzenoux E, Pesquet J, Tourneret J, Hero AO, McLaughlin S (2016) A survey of stochastic simulation and optimization methods in signal processing. IEEE J Sel Top Signal Process 10(2):224–241. https://doi.org/10.1109/JSTSP.2015.2496908

Plona TJ, Cook JM (1995) Effects of stress cycles on static and dynamic Young’s moduli in Castlegate sandstone. Paper presented at the 35th U.S. symposium on rock mechanics (USRMS), Reno, Nevada, 1 Jan 1995

Podio AL, Gregory AR, Gray KE (1968) Dynamic properties of dry and water-saturated green river shale under stress. Soc Pet Eng J. https://doi.org/10.2118/1825-pa

Saasen A, Dahl B, Jødestøl K (2013) Particle size distribution of top-hole drill cuttings from norwegian sea area offshore wells. Part Sci Technol. https://doi.org/10.1080/02726351.2011.648824

Sambridge M, Mosegaard K (2002) Monte Carlo methods in geophysical inverse problems. Rev Geophys 40(3):3-1–3-29. https://doi.org/10.1029/2000rg000089

Santarelli FJ, Marsala AF, Brignoli M, Rossi E, Bona N (1998) Formation evaluation from logging on cuttings. SPE Reserv Eng (Soc Pet Eng). https://doi.org/10.2118/36851-pa

Shi X, Yang L, Li D, Ding X (2018) Mechanical characterization of Longmaxi marine shale by nanoindentation. Paper presented at the ISRM international symposium—10th Asian rock mechanics symposium, Singapore, 1 Jan 2018

Shorshorov MK, Bulychev SI, Alekhin VP (1987) Work of plastic and elastic deformation during indenter indentation. Sov Phys Dokl 26(769):769–771

Slim M, Abedi S, Bryndzia LT, Ulm F-J (2019) Role of organic matter on nanoscale and microscale creep properties of source rocks. J Eng Mech. https://doi.org/10.1061/(asce)em.1943-7889.0001538

Sneddon IN (1965) The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int J Eng Sci. https://doi.org/10.1016/0020-7225(65)90019-4

Stuckman MY, Edenborn HM, Lopano CL, Hakala JA (2018) Advanced characterization and novel waste management for drill cuttings from marcellus shale energy development. In: Unconventional resources technology conference, Houston, Texas, 23–25 July 2018. https://doi.org/10.15530/urtec-2018-2883168

Stuckman M, Edenborn HM, Lopano C, Hakala JA (2018) Advanced characterization and novel waste management for drill cuttings from Marcellus shale energy development. Paper presented at the SPE/AAPG/SEG unconventional resources technology conference, Houston, Texas, USA, 9 Aug 2018

Swadener JG, Pharr GM (2001) Indentation of elastically anisotropic half-spaces by cones and parabolae of revolution. Philos Mag A Phys Condens Matter Struct Defects Mech Prop 81(2):447–466. https://doi.org/10.1080/01418610108214314

Swadener JG, Rho JY, Pharr GM (2001) Effect of anisotropy on elastic moduli measured by nanoindentation in human tibial cortical bone. J Biomed Mater Res 57(1):108–112. https://doi.org/10.1002/1097-4636(200110)57:1%3c108:AID-JBM1148%3e3.0.CO;2-6

Takahashi T, Tanaka S (2010) Rock physics model for interpreting dynamic and static Young’s moduli of soft sedimentary rocks. In: ISRM international symposium on 6th Asian rock mechanics symposium, 2010, pp 23–27

Ternovskii AP, Alekhin VP, Shorshorov MK, Khrushchov MM, Skvortsov VN (1973) Micromechanical testing of materials by depression. Zavod Lab 39:1620–1624

The MathWork I (2019) Symbolic Math Toolbox. Natick, Massachusetts, United State. Retrieved from https://www.mathworks.com/help/symbolic/

Uboldi V, Civolani L, Zausa F (1999) Rock strength measurements on cuttings as input data for optimizing drill bit selection. Paper presented at the SPE Annual Technical Conference And Exhibition, Houston, Texas, 1 Jan 1999

Ullemeyer K, Lokajíček T, Vasin RN, Keppler R, Behrmann JH (2018) Extrapolation of bulk rock elastic moduli of different rock types to high pressure conditions and comparison with texture-derived elastic moduli. Phys Earth Planet Int 275:32–43. https://doi.org/10.1016/j.pepi.2018.01.001

Ulm F-J, Abousleiman Y (2006) The nanogranular nature of shale. Acta Geotech 1(2):77–88. https://doi.org/10.1007/s11440-006-0009-5

Vandamme M (2008) The nanogranular origin of concrete creep: a nanoindentation investigation of microstructure and fundamental properties of calcium-silicate-hydrates. In: Ph.D. Dissertation, Massachusetts Institute of Technology, Cambridge

Vasconcelos G, Lourenço PB, Alves CAS, Pamplona J (2008) Ultrasonic evaluation of the physical and mechanical properties of granites. Ultrasonics 48(5):453–466. https://doi.org/10.1016/j.ultras.2008.03.008

Vernik L, Nur A (1992) Ultrasonic velocity and anisotropy of hydrocarbon source rocks. Geophysics 57(5):670–751

Vlassak JJ, Nix WD (1993) Indentation modulus of elastically anisotropic half spaces. Philos Mag A Phys Condens Matter Struct Defects Mech Prop 42(8):1223–1245. https://doi.org/10.1080/01418619308224756

Vlassak JJ, Nix WD (1994) Measuring the elastic properties of anisotropic materials by means of indentation experiments. J Mech Phys Solids 42(8):1223–1245. https://doi.org/10.1016/0022-5096(94)90033-7

Vlassak JJ, Ciavarella M, Barber JR, Wang X (2003) The indentation modulus of elastically anisotropic materials for indenters of arbitrary shape. J Mech Phys Solids 51(9):1701–1721. https://doi.org/10.1016/S0022-5096(03)00066-8

Wang Z (2002) Seismic anisotropy in sedimentary rocks, part 1: a single-plug laboratory method. Geophysics 67(5):1348–1672. https://doi.org/10.1190/1.1512787

Wang Y, Han D-h, Aldin S, Aldin M, Qin X (2018) Static and dynamic Young’s moduli and Poisson’s ratios of Eagle Ford Shale under triaxial tests. In: SEG technical program expanded abstracts 2018. Society of Exploration Geophysicists, pp 3613–3617. https://doi.org/10.1190/segam2018-2998339.1

Willis JR (1966) Hertzian contact of anisotropic bodies. J Mech Phys Solids 14:163–176. https://doi.org/10.1016/0022-5096(66)90036-6

Yan F, Han DH, Yao Q (2016) Physical constraints on c 13 and δ for transversely isotropic hydrocarbon source rocks. Geophys Prospect 64:1524–1536. https://doi.org/10.1111/1365-2478.12265

Zausa F, Civolani L, Brignoli M, Santarelli FJ (1997) Real-time wellbore stability analysis at the rig-site. Paper presented at the SPE/IADC drilling conference, Amsterdam, Netherlands, 1 Jan 1997

Zeng Q, Wu Y, Liu Y, Zhang G (2019) Determining the micro-fracture properties of Antrim gas shale by an improved micro-indentation method. J Nat Gas Sci Eng 62:224–235. https://doi.org/10.1016/j.jngse.2018.12.013

Zhang F, Guo H, Hu D, Shao J-F (2018) Characterization of the mechanical properties of a claystone by nano-indentation and homogenization. Acta Geotech 13(6):1395–1404. https://doi.org/10.1007/s11440-018-0691-0

Zhao J, Zhang D, Wu T, Tang H, Xuan Q, Jiang Z, Dai C (2019) Multiscale approach for mechanical characterization of organic-rich shale and its application. Int J Geomech 19(1):04018180. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001281

Acknowledgements

The authors would like to acknowledge the use of the Materials Characterization Facility at Texas A&M University and thank Dr. Wilson Serem for his technical assistance. We also thank the US Department of Energy (Award DE-FE0031579) and the Halliburton Sperry team for sponsoring this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martogi, D., Abedi, S. Microscale approximation of the elastic mechanical properties of randomly oriented rock cuttings. Acta Geotech. 15, 3511–3524 (2020). https://doi.org/10.1007/s11440-020-01020-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01020-9