Abstract

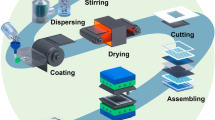

This paper established a numerical model for a solid oxide fuel cell (SOFC) button cell, focusing on the effects of finger-like channels on the gas transport process in the anode support. The current densities of channelled button cell and un-channelled button cell are compared at different operating temperature and voltage with H2 as the fuel. The H2 transport is discussed in detail, such as the mole fraction distribution of H2 in the porous layer, the diffusion flux and convective flux of H2. It is found that the performance of SOFC can be improved by 2.60 % at 800 °C, 0.5 V, compared with un-channelled SOFC due to the improved gas transport by the finger-like channels. Then, the model is further extended to study 2D-planar SOFC fuelled with syngas. The mole fraction gradients of H2, CO, CH4 and CO are all substantially reduced by the finger-like channels compared to un-channelled planar cell. It is found that the SOFC performance is improved by 5.93 % at 800 °C, 0.5 V, when syngas fuel is used. The present study clearly demonstrated that the use of finger-like channels in the anode support is effective in improving the gas transport and the SOFC performance. The present model can be employed for subsequent optimization of the channel configuration for further performance improvement.

摘要

本文建立了固体氧化物纽扣燃料电池的数学模型,研究了阳极支撑中指孔状通道对气体传输过程的影响。比较了当氢气作为燃料,加通道和未加通道的纽扣燃料电池在不同温度和工作电压下的电流密度。讨论了电池多孔阳极内的氢气的摩尔分数分布、扩散通量以及对流通量分布。发现在800 oC, 0.5 V 下, 加通道的纽扣电池由于气体传输的优化,性能比未加通道提高了2.60 %。模型被用于模拟合成气作为燃料的平板固体氧化物燃料电池。在有指孔状通道的情况下,H2,CO,CH4 和CO的摩尔分数梯度被有效降低,800 oC,0.5 V时,电池性能提高了5.93 %。本文论证了指孔状结构应用于阳极支撑层时,对气体传输优化和电池性能提升的有效性。模型可被用于进一步的通道结构设计和优化。

Similar content being viewed by others

References

Assabumrungrat S, Arpornwichanop A, Sukwattanajaroon V et al (2016) Integrated solid oxide fuel cell systems for electrical power generation—a review. In: Lehr JH, Keeley J, Kingery TB (eds) Alternative energy and shale gas encyclopedia. Wiley, Hoboken. doi:10.1002/9781119066354.ch51

Choudhury A, Chandra H, Arora A (2013) Application of solid oxide fuel cell technology for power generation—a review. Renew Sustain Energy Rev 20:430–442

Ni M (2012) Modeling of SOFC running on partially pre-reformed gas mixture. Int J Hydro Energy 37:1731–1745

Ni M, Leung MK, Leung DY (2009) Ammonia-fed solid oxide fuel cells for power generation—a review. Int J Energy Res 33:943–959

Zhang HC, Chen JC, Zhang JJ (2013) Performance analysis and parametric study of a solid oxide fuel cell fueled by carbon monoxide. Int J Hydro Energy 38:16354–16364

Singhal SC, Kendall K (2003) High-temperature solid oxide fuel cells: fundamentals, design and applications. Elsevier, Amsterdam

Tsipis EV, Kharton VV (2008) Electrode materials and reaction mechanisms in solid oxide fuel cells: a brief review. J Solid State Electrochem 12:1367–1391

Othman MHD, Wu Z, Droushiotis N et al (2010) Morphological studies of macrostructure of Ni–CGO anode hollow fibres for intermediate temperature solid oxide fuel cells. J Membr Sci 360:410–417

Droushiotis N, Doraswami U, Kanawka K et al (2009) Characterization of NiO–yttria stabilised zirconia (YSZ) hollow fibres for use as SOFC anodes. Solid State Ionics 180:1091–1099

Meng X, Yang N, Meng B et al (2012) Microstructure tailoring of the nickel–yttria stabilised zirconia (Ni–YSZ) cermet hollow fibres. Ceram Int 38:6327–6334

Dong D, Shao X, Xie K et al (2014) Microchanneled anode supports of solid oxide fuel cells. Electrochem Commun 42:64–67

Doraswami U, Shearing P, Droushiotis N et al (2011) Modelling the effects of measured anode triple-phase boundary densities on the performance of micro-tubular hollow fiber SOFCs. Solid State Ionics 192:494–500

Doraswami U, Droushiotis N, Kelsall GH (2010) Modelling effects of current distributions on performance of micro-tubular hollow fibre solid oxide fuel cells. Electrochim Acta 55:3766–3778

Xia C, Liu M (2002) Microstructures, conductivities, and electrochemical properties of Ce0.9Gd0.1O2 and GDC–Ni anodes for low-temperature SOFCs. Solid State Ionics 152–153:423–430

Grosso RL, Bertolete M, Machado IF et al (2013) Ionic conductivity and phase stability of spark plasma sintered scandia and ceria-stabilized zirconia. Solid State Ionics 230:48–51

Tang J, Cai C, Xiao T (2012) Modeling and predicting the electrical conductivity of composite cathode for solid oxide fuel cell by using support vector regression. Int J Mod Phys B 26:1250093

Chen B, Xu H, Chen L et al (2016) Modelling of one-step methanation process combining SOECs and Fischer-Tropsch-like reactor. J Electrochem Soc 163:F3001–F3008

Shi YX, Li C, Cai NS (2011) Experimental characterization and mechanistic modeling of carbon monoxide fueled solid oxide fuel cell. J Power Sources 196:5526–5537

Zheng K, Ni M (2016) Reconstruction of solid oxide fuel cell electrode microstructure and analysis of its effective conductivity. Sci Bull 61:78–85

Jiao Z, Shikazono N (2016) 3D reconstruction size effect on the quantification of solid oxide fuel cell nickel–yttria-stabilized-zirconia anode microstructural information using scanning electron microscopy-focused ion beam technique. Sci Bull. doi:10.1007/s11434-016-1044-8

Andersson M, Yuan JL, Sunden B (2012) SOFC modeling considering electrochemical reactions at the active three phase boundaries. Int J Heat Mass Transf 55:773–788

Ni M (2013) Modeling and parametric simulations of solid oxide fuel cells with methane carbon dioxide reforming. Energy Convers Manag 70:116–129

Chen L, Yao M, Xia C (2014) Anode substrate with continuous porosity gradient for tubular solid oxide fuel cells. Electrochem Commun 38:114–116

Williford RE, Chick LA, Maupin GD et al (2003) Diffusion limitations in the porous anodes of SOFCs. J Electrochem Soc 150:A1067–A1072

Haberman BA, Young JB (2004) Three-dimensional simulation of chemically reacting gas flows in the porous support structure of an integrated-planar solid oxide fuel cell. Int J Heat Mass Transf 47:3617–3629

Gould NI, Scott JA, Hu Y (2007) A numerical evaluation of sparse direct solvers for the solution of large sparse symmetric linear systems of equations. ACM Trans Math Softw 33:10

Acknowledgments

This work was supported by a Grant (PolyU 152127/14E) from Research Grant Council, University Grants Committee, Hong Kong SAR.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

SPECIAL TOPIC: Modeling of Solid Oxide Fuel Cells

Appendix: List of symbols

Appendix: List of symbols

- \( AV \) :

-

Specific surface area ratio, 2.381 × 105 m−1

- D y :

-

Distance from the anode-electrolyte interface (AEI), in y direction (μm)

- D x :

-

Distance from the middle cut line of the button cell, in x direction (μm)

- D x, p :

-

Distance from the inlet of the planar cell, in x direction (μm)

- \( F \) :

-

Faraday constant, 96,485 C/mol

- \( i_{\text{c}} \) :

-

Local current source for cathode (A/m3)

- \( i_{{{\text{a}},{\text{H}}_{2} }} \) :

-

Local current source by H2 (A/m3)

- \( i_{{{\text{a}},{\text{CO}}}} \) :

-

Local current source by CO (A/m3)

- \( i_{{{\text{o}},{\text{c}}}} \) :

-

Exchange current density for cathode reaction (A/m2)

- \( i_{{{\text{o}},{\text{H}}_{2} }} \) :

-

Exchange current density for oxidation of H2 (A/m2)

- \( i_{{{\text{o}},{\text{CO}}}} \) :

-

Exchange current density for oxidation of CO (A/m2)

- \( N_{{{\text{conv}}.{\text{H}}_{2} }} \) :

-

Convective flux of H2 in y direction (kg/(m2 s))

- \( N_{{{\text{diff}}.{\text{H}}_{2} }} \) :

-

Diffusive flux of H2 in y direction (kg/(m2 s))

- \( P_{\text{ch}} \) :

-

Average power density of channelled cell (W/m2)

- \( P_{{{\text{un}} - {\text{ch}}}} \) :

-

Average power density of un-channelled cell (W/m2)

- \( p_{{{\text{H}}_{2} }} \) :

-

Species partial pressure, atm, subscript “.ref” meaning the reference value

- \( R \) :

-

Gas constant, 8.314 J/(mol K)

- T :

-

Operating temperature (K)

- \( \sigma \) :

-

Conductivity of material as subscripted (S/m)

- \( \eta_{{{\text{act}}.{\text{a}}/{\text{c}}}} \) :

-

Activation overpotential (V)

- η :

-

Percentage of power density enhancement (%)

- η conc, u :

-

Concentration overpotential of the un-channelled button cell

- η conc, c :

-

Concentration overpotential of the channelled button cell

- \( \varepsilon \) :

-

Porosity

- \( \xi \) :

-

Tortuosity

About this article

Cite this article

Chen, B., Xu, H. & Ni, M. Modelling of finger-like channelled anode support for SOFCs application. Sci. Bull. 61, 1324–1332 (2016). https://doi.org/10.1007/s11434-016-1131-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11434-016-1131-x