Abstract

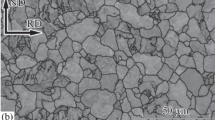

A new quenching-partitioning-tempering (Q-P-T) process was designed based on the recently developed quenching and partitioning (Q & P) treatment by Speer et al. The orientation relationships (ORs) of martensite (α) in Q-P-T steel tempered under different conditions were investigated using a scanning electron microscope with an electron backscatter diffraction unit. The morphology and crystallography of lath martensite within a packet were analyzed. Martensites exhibiting an initial austenite (γ) grain in the orientation image map of different samples were chosen and their {111}α pole figures were drawn. The pole figures were fitted according to the ideal Kurdjumov-Sachs (K-S) and Nishiyama-Wasserman (N-W) ORs, which were calculated using Matlab and with a γ crystal-oriented (001)γ[100]γ as the reference frame. The martensite OR in the Q-P-T steel follows both the K-S and N-W ORs; however, the K-S OR is predominant. This characteristic does not change in the samples further tempered at different temperatures.

Similar content being viewed by others

References

Speer J, Matlock D K, Rizzo F C, et al. Partitioning of carbon from supersaturated plates of ferrite with application to steel processing and fundamentals of the bainite transformation. Current Opinion Solid State Mater Sci, 2004, 8(3–4): 219–237

Speer J, Matlock D K, De Cooman B C, et al. Carbon partitioning into austenite after martensite transformation. Acta Mater, 2003, 51(9): 2611–2622

Hsu T Y. Design of structure, composition and heat treatment process for high strength steel. Mater Sci Forum, 2007, 561–565(3): 2283–2286

Hsu T Y. Quenching-partitioning-tempering (Q-P-T) process for ultra-high strength steel. Int Heat Treatment Surface Eng, 2008, 2(2): 64–58

Kitahara H, Ueji R, Tsuji N, et al. Crystallographic features of lath martensite in low-carbon steel. Acta Mater, 2006, 54(5): 1279–1288

Kitahara H, Ueji R, Ueda M, et al. Crystallographic analysis of plate martensite in Fe-28.5 at.% Ni by FE-SEM/EBSD. Mater Characterization, 2005, 54(4–5): 378–386

Yoshitaka A, Kazunari H, Kaneaki T. Crystallographic analysis of grain boundary Bcc-precipitates in a Ni-Cr alloy by FESEM/EBSD and TEM/Kikuchi line methods. Mater Sci Engi A, 2005, 412(1–2): 252–263

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, S., Yu, H. Investigation on martensitic steel using a quenching-partitioning-tempering process via electron backscatter diffraction analysis. Sci. China Technol. Sci. 55, 646–651 (2012). https://doi.org/10.1007/s11431-011-4658-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4658-8