Abstract

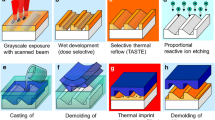

In this paper, the replication process of large area nanoimprint stamp with small critical dimension (CD) loss was investigated, using the thin residual layer nanoimprint lithography (NIL) technology. The residual layer thickness was optimized by changing the spin-coated resist thickness. The dependences of the residual layer etching rate on gas flow, chamber pressure, and RF power were investigated, and the optimized process conditions were established. By means of the thin residual layer NIL technique and optimized residual layer etching process, large area stamp with small CD loss and multi-orientation patterns was successfully replicated on 2-inch SiO2/Si wafer. The CD loss was controlled within 5 nm. The replicated stamp showed high performance in the patterning with thermal NIL. The replication process reported in this work could also be used to fabricate large area nanostructures with small CD loss.

Similar content being viewed by others

References

Chou S Y, Kruss P R, Zhang W, et al. Sub-10 nm imprint lithography and applications. J Vac Sci Technol B, 1997, 15: 2897–2904

Maximov I, Carlberg P, Wallin D, et al. Nanoimprint lithography for fabrication of three-terminal ballistic junctions in In/GaInAs. Nanotech, 2002, 13: 666–668

Ahn S W, Lee K D, Kim J S. Fabrication of subwavelength aluminum wire grating using nanoimprint lithography and reactive ion etching. Microelectron Eng, 2005, 78–79: 314–318

Wu W, Cui B, Sun X Y, et al. Large area high density quantized magnetic disks fabricated using nanoimprint lithography. J Vac Sci Technol B, 1998, 16: 3825–3829

Falconnet D, Pasqui D, Park S, et al. A novel approach to produce protein nanopatterns by combining nanoimprint lithography and molecular self-assembly. Nano Lett, 2004, 4: 1909–1914

Park S, Schift H, Solak H H, et al. Stamps for nanoimprint lithography by extreme ultraviolet interference lithography. J Vac Sci Technol B, 2004, 22: 3246–3250

Chu J K, Meng F T, Han Z T, et al. Large area mold fabrication for the nanoimprint lithography using electron beam lithography. Sci China Tech Sci, 2010, 53: 248–252

Luo G, Xie G Y, Zhang Y Y, et al. Scanning probe lithography for nanoimprinting mould fabrication. Nanotech, 2006, 17: 3018–3022

Beck M, Graczyk M, Maximov I, et al. Improving stamps for 10 nm level wafer scale nanoimprint lithography. Microelectron Eng, 2002, 61–62: 441–448

Meng F T, Luo G, Montelius L, et al. Fabrication of sub-100 nm metal nanowire structure by zero residual nanoimprint lithography. In: The 9th International Conference on Nanoimprint and Nanoprint Technology, Oresund & Copenhagen, October 13–15, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, F., Guan, L., Wang, Z. et al. Replication of large area nanoimprint stamp with small critical dimension loss. Sci. China Technol. Sci. 55, 600–605 (2012). https://doi.org/10.1007/s11431-011-4695-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4695-3