Abstract

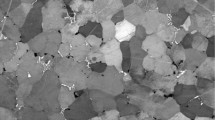

The Portevin–Le Châtelier (PLC) instability is commonly observed in Al–Mg alloys and is manifested in serrated flow within the stress–strain response. We investigate the persistence of this instability with reduction in grain size by studying an ultrafine-grained (ufg) aluminum alloy (Al5083) and a conventional grain size Al5083. Micro-scale tensile tests combined with digital image correlation (DIC) reveal strength anisotropy and heterogeneity of the deformation in the three material directions (extrusion, rolled, and transverse). For the same applied displacement rate, the PLC effect in ufg-Al5083 is observed only over a small strain range immediately following the yield, while the coarse-grained Al5083 exhibits serrated flow over nearly the entire plastic strain range. These observations are explained using the stability analysis of Hähner (Acta Mater 45:3695–3707, 1997), and implications for nanocrystalline (nc) alloys are discussed.

Similar content being viewed by others

References

Witkin DB, Lavernia EJ (2006) Synthesis and mechanical behavior of nanostructured materials via cryomilling. Prog Mater Sci 51:1–60. doi:10.1016/j.pmatsci.2005.04.004

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci 45:103–189. doi:10.1016/S0079-6425(99)00007-9

Newbery AP, Nutt SR, Lavernia EJ (2006) Multi-scale al 5083 for military vehicles with improved performance. JOM 58:56–61. doi:10.1007/s11837-006-0216-4

Ye J, Han BQ, Lee Z, Ahn B, Nutt SR, Schoenung JM (2005) A tri-modal aluminum based composite with super-high strength. Scr Mater 53:481–486. doi:10.1016/j.scriptamat.2005.05.004

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Prog Mater Sci 51:427–556. doi:10.1016/j.pmatsci.2005.08.003

Wang YM, Ma E (2004) Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater 52:1699. doi:10.1016/j.actamat.2003.12.022

Robinson JM, Shaw MP (1994) Microstructural and mechanical influences on dynamic strain aging phenomena. Int Mater Rev 39:113–122

Zaiser M, Hähner P (1997) A unified description of strain-rate softening instabilities. Mater Sci Eng A 238:399. doi:10.1016/S0921-5093(97)00468-1

Zaiser M, Haehner P (1997) Oscillatory modes of plastic deformation: theoretical concepts. Physica Status Solidi (B). Basin Res 199:267–330

Hähner P (1997) On the critical conditions of the Portevin—Le-Chatelier effect. Acta Mater 45:3695–3707. doi:10.1016/S1359-6454(97)00066-9

Brindley BJ, Worthington PJ (1969) Serrated yielding in aluminum-3% magnesium. Acta Metall 17:1357–1361. doi:10.1016/0001-6160(69)90153-9

Cheng X-M, Morris JG (2000) The anisotropy of the portevin-le chatelier effect in aluminum alloys. Scr Mater 43:651–658. doi:10.1016/S1359-6462(00)00474-7

Jiang H, Zhang Q, Chen X, Chen Z, Jiang Z, Wu X, Fan J (2007) Three types of portevin–le chatelier effects: experiment and modelling. Acta Mater 55:2219. doi:10.1016/j.actamat.2006.10.029

Kubin LP, Estrin Y (1990) Evolution of dislocation densities and the critical conditions for the portevin–le chatelier effect. Acta Metall Mater 38:697–708. doi:10.1016/0956-7151(90)90021-8

Dziadon A (1996) The effect of grain size on serrated flow in nickel. Scr Mater 34:375–380. doi:10.1016/S0956-716X(95)00537-6

Bouabdallah K, Balland P, Tabourot L, Vacher P (2007) Contribution of kinematic field measurements to the modelling of the portevin–le cha?Telier effect by the image correlation method. J Strain Anal Eng Des 42:589–594. doi:10.1243/03093247JSA312

Tong W, Tao H, Zhang N, Hector LG Jr (2005) Time-resolved strain mapping measurements of individual portevin–le chatelier deformation bands. Scr Mater 53:87–92. doi:10.1016/j.scriptamat.2005.03.020

Besnard G, Hild F, Roux S (2006) “Finite-element” displacement fields analysis from digital images: application to Portevin–Le Châtelier bands. Exp Mech 46:789–803. doi:10.1007/s11340-006-9824-8

Chu TC, Ranson WF, Sutton MA (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25:232. doi:10.1007/BF02325092

Park KT, Park JH, Lee YS, Nam WJ (2005) Microstructures developed by compressive deformation of coarse grained and ultrafine grained 5083 al alloys at 77 k and 298 k. Mater Sci Eng A 408:102–109. doi:10.1016/j.msea.2005.07.040

Soer WA, De Hosson JTM, Minor AM, Morris JW Jr, Stach EA (2004) Effects of solute mg on grain boundary and dislocation dynamics during nanoindentation of al-mg thin films. Acta Mater 52:5783–5790. doi:10.1016/j.actamat.2004.08.032

Lebyodkin M, Dunin-Barkowskii L, Bréchet Y, Estrin Y, Kubin LP (2000) Spatio-temporal dynamics of the portevin–le chatelier effect: experiment and modelling. Acta Mater 48:2529–2541. doi:10.1016/S1359-6454(00)00067-7

Bharathi MS, Rajesh S, Ananthakrishna G (2003) A dynamical model for the portevin–le chatelier bands. Scr Mater 48:1355. doi:10.1016/S1359-6462(02)00653-X

Kok S, Beaudoin AJ, Tortorelli DA, Lebyodkin M, Kubin L, Fressengeas C (2003) Simulation of the portevin–le chatelier effect using polycrystal plasticity. J Phys IV: JP 105:191. doi:10.1051/jp4:20030187

Kok S, Bharathi MS, Beaudoin AJ, Fressengeas C, Ananthakrishna G, Kubin LP, Lebyodkin M (2003) Spatial coupling in jerky flow using polycrystal plasticity. Acta Mater 51:3651–3662. doi:10.1016/S1359-6454(03)00114-9

Mesarovic S (1995) Dynamic strain aging and plastic instabilities. J Mech Phys Solids 43:671–700. doi:10.1016/0022-5096(95)00010-G

Yang SY, Tong W (2006) A perturbation analysis of the unstable plastic flow pattern evolution in an aluminum alloy. Int J Solids Struct 43:5931. doi:10.1016/j.ijsolstr.2005.07.041

Rizzi E, Haehner P (2004) On the portevin–le chatelier effect: theoretical modeling and numerical results. Int J Plast 20:121–165. doi:10.1016/S0749-6419(03)00035-4

Wei Q, Cheng S, Ramesh KT, Ma E (2004) Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: Fcc versus bcc metals. Mater Sci Eng A 381:71. doi:10.1016/j.msea.2004.03.064

Acknowledgements

The authors would like to thank Prof. E.J. Lavernia for providing the material samples and for the TEM images of ufg-Al5083. SPJ, BC and KTR acknowledge the financial support received from the Army Research Laboratory (W911NF-06-2-0006). CE and KJH acknowledge the financial support received from AFOSR under the MEANS-2 Program (Grant No. FA9550-05-1-0173).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Joshi, S.P., Eberl, C., Cao, B. et al. On the Occurrence of Portevin–Le Châtelier Instabilities in Ultrafine-Grained 5083 Aluminum Alloys. Exp Mech 49, 207–218 (2009). https://doi.org/10.1007/s11340-008-9208-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-008-9208-3