Abstract

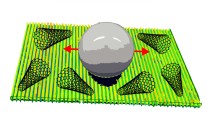

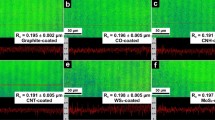

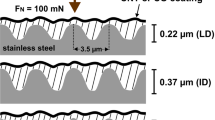

In the present study, a systematic evaluation of the influence of the surface roughness on the lubrication activity of multi-wall carbon nanotubes (MWCNT) and onion-like carbon (OLC) is performed. MWCNT and OLC are chosen as they both present an sp2-hybridization of carbon atoms, show a similar layered atomic structure, and exhibit the potential to roll on top of a surface. However, their morphology (size and aspect ratio) clearly differs, allowing for a methodical study of these differences on the lubrication effect on systematically varied surface roughness. Stainless steel platelets with different surface finishing were produced and coated by electrophoretic deposition with OLC or MWCNT. The frictional behavior is recorded using a ball-on-disk tribometer, and the resulting wear tracks are analyzed by scanning electron microscopy in order to reveal the acting tribological mechanisms. It is found that the lubrication mechanism of both types of particles is traced back to a mixture between a rolling motion on the surfaces and particle degradation, including the formation of nanocrystalline graphitic layers. This investigation further highlights that choosing the suitable surface finish for a tribological application is crucial for achieving beneficial tribological effects of carbon nanoparticle lubricated surfaces.

Similar content being viewed by others

References

Holmberg, K., Andersson, P., Erdemir, A.: Global energy consumption due to friction in passenger cars. Tribol. Int. 47, 221–234 (2012). https://doi.org/10.1016/j.triboint.2011.11.022

Donnet, C., Erdemir, A.: Solid lubricant coatings: recent developments and future trends. Tribol. Lett. 17, 389–397 (2004)

Aouadi, S.M., Gao, H., Martine, A., Scharf, T.W., Muratore, C.: Lubricious oxide coatings for extreme temperature applications: a review. Surf. Coat. Technol. 257, 266–277 (2014)

Li, Y., Li, B.X., Zou, W.J.: The relationship between nanocrystalline structure and frictional properties of nanodiamond/Ni composite coatings by brush plating. Appl. Mech. Mater. 80–81, 683–687 (2011). https://doi.org/10.4028/www.scientific.net/AMM.80-81.683

Hirata, A., Yoshioka, N.: Sliding friction properties of carbon nanotube coatings deposited by microwave plasma chemical vapor deposition. Tribol. Int. 37, 893–898 (2004). https://doi.org/10.1016/j.triboint.2004.07.005

Miyoshi, K., Street Jr., K.W., Vander Wal, R.L., Andrews, R., Sayir, A.: Solid lubrication by multiwalled carbon nanotubes in air and in vacuum. Tribol. Lett. 19, 191–201 (2005). https://doi.org/10.1007/s11249-005-6146-4

Reinert, L., Suárez, S., Rosenkranz, A.: Tribo-mechanisms of carbon nanotubes: friction and wear behavior of CNT-reinforced nickel matrix composites and CNT-coated bulk nickel. Lubricants 4, 11 (2016). https://doi.org/10.3390/lubricants4020011

Gogotsi, Y., Presser, V.: Carbon Nanomaterials. CRC Press, Boca Raton (2014). ISBN 9781138076815

Bakshi, S.R., Lahiri, D., Agarwal, A.: Carbon nanotube reinforced metal matrix composites—a review. Int. Mater. Rev. 55, 41–64 (2010). https://doi.org/10.1179/095066009X12572530170543

Mochalin, V.N., Shenderova, O., Ho, D., Gogotsi, Y.: The properties and applications of nanodiamonds. Nat. Nanotechnol. 7, 11–23 (2012). https://doi.org/10.1038/nnano.2011.209

Iijima, S.: Helical microtubules of graphitic carbon. Nature 354, 56–58 (1991)

Cebik, J., McDonough, J.K., Peerally, F., Medrano, R., Neitzel, I., Gogotsi, Y., Osswald, S.: Raman spectroscopy study of the nanodiamond-to-carbon onion transformation. Nanotechnology 24, 1–10 (2013). https://doi.org/10.1088/0957-4484/24/20/205703

Zeiger, M., Jäckel, N., Aslan, M., Weingarth, D., Presser, V.: Understanding structure and porosity of nanodiamond-derived carbon onions. Carbon 84, 584–598 (2015). https://doi.org/10.1016/j.carbon.2014.12.050

Reinert, L., Lasserre, F., Gachot, C., Grützmacher, P., MacLucas, T., Souza, N., Mücklich, F., Suarez, S.: Long-lasting solid lubrication by CNT-coated patterned surfaces. Sci. Rep. (2017). https://doi.org/10.1038/srep42873

Hu, J.J., Jo, S.H., Ren, Z.F., Voevodin, A., Zabinski, J.S.: Tribological behavior and graphitization of carbon nanotubes grown on 440C stainless steel. Tribol. Lett. 19, 119–125 (2005). https://doi.org/10.1007/s11249-005-5091-6

Tunable friction behavior of oriented carbon nanotube films: Dickrell, P.L., Pal, S.K., Bourne, G.R., Muratore, C., Voevodin, a. a., Ajayan, P.M., Schadler, L.S., Sawyer, W.G. Tribol. Lett. 24, 85–90 (2006). https://doi.org/10.1007/s11249-006-9162-0

Zhang, X., Luster, B., Church, A., Muratore, C., Voevodin, A.A., Kohli, P., Aouadi, S., Talapatra, S.: Carbon nanotube-MoS2 composites as solid lubricants. ACS Appl. Mater. Interfaces 1, 735–739 (2009). https://doi.org/10.1021/am800240e

Arai, S., Fujimori, A., Murai, M., Endo, M.: Excellent solid lubrication of electrodeposited nickel-multiwalled carbon nanotube composite films. Mater. Lett. 62, 3545–3548 (2008). https://doi.org/10.1016/j.matlet.2008.03.047

Chen, W.X., Tu, J.P., Wang, L.Y., Gan, H.Y., Xu, Z.D., Zhang, X.B.: T ribological application of carbon nanotubes in a metal-based composite coating and composites. Carbon 41, 215–222 (2003)

Kim, K.T., Cha, S.I., Hong, S.H.: Hardness and wear resistance of carbon nanotube reinforced Cu matrix nanocomposites. Mater. Sci. Eng. A 449–451, 46–50 (2007). https://doi.org/10.1016/j.msea.2006.02.310

Scharf, T.W., Neira, A., Hwang, J.Y., Tiley, J., Banerjee, R.: Self-lubricating carbon nanotube reinforced nickel matrix composites. J. Appl. Phys. 106, 013508 (2009). https://doi.org/10.1063/1.3158360

Chen, C.S., Chen, X.H., Xu, L.S., Yang, Z., Li, W.H.: Modification of multi-walled carbon nanotubes with fatty acid and their tribological properties as lubricant additive. Carbon 43, 1660–1666 (2005). https://doi.org/10.1016/j.carbon.2005.01.044

Peng, Y., Hu, Y., Wang, H.: Tribological behaviors of surfactant-functionalized carbon nanotubes as lubricant additive in water. Tribol. Lett. 25, 247–253 (2006). https://doi.org/10.1007/s11249-006-9176-7

Lu, H.F., Fei, B., Xin, J.H., Wang, R.H., Li, L., Guan, W.C.: Synthesis and lubricating performance of a carbon nanotube seeded miniemulsion. Carbon 45, 936–942 (2007). https://doi.org/10.1016/j.carbon.2007.01.001

Dickrell, P.L., Sinnott, S.B., Hahn, D.W., Raravikar, N.R., Schadler, L.S., Ajayan, P.M., Sawyer, W.G.: Frictional anisotropy of oriented carbon nanotube surfaces. Tribol. Lett. 18, 59–62 (2005). https://doi.org/10.1007/s11249-004-1752-0

Ni, B., Sinnott, S.B.: Tribological properties of carbon nanotube bundles predicted from atomistic simulations. Surf. Sci. 487, 87–96 (2001). https://doi.org/10.1016/S0039-6028(01)01073-1

Martin, J.M., Ohmae, N.: Nanolubricants. Wiley, New York (2008). ISBN 978-0-470-06552-5

Hirata, A., Igarashi, M., Kaito, T.: Study on solid lubricant properties of carbon onions produced by heat treatment of diamond clusters or particles. Tribol. Int. 37, 899–905 (2004). https://doi.org/10.1016/j.triboint.2004.07.006

Park, S., Srivastava, D., Cho, K.: Generalized chemical reactivity of curved surfaces: carbon nanotubes. Nano Lett. 3, 1273–1277 (2003). https://doi.org/10.1021/nl0342747

Street, K.W., Marchetti, M., Vander Wal, R.L., Tomasek, A.J.: Evaluation of the tribological behavior of nano-onions in Krytox 143AB. Tribol. Lett. 16, 143–149 (2004)

Bucholz, E.W., Phillpot, S.R., Sinnott, S.B.: Molecular dynamics investigation of the lubrication mechanism of carbon nano-onions. Comput. Mater. Sci. 54, 91–96 (2012). https://doi.org/10.1016/j.commatsci.2011.09.036

Menezes, P.L., Kishore, Kailas, S.V.: Effect of surface roughness parameters and surface texture on friction and transfer layer formation in tin–steel tribo-system. J. Mater. Process. Technol. 208, 372–382 (2008). https://doi.org/10.1016/j.jmatprotec.2008.01.003

Persson, B.N.J., Albohr, O., Tartaglino, U., Volokitin, A.I., Tosatti, E.: On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter. (2005). https://doi.org/10.1088/0953-8984/17/1/r01

Sahin, M., Çetinarslan, C.S., Akata, H.E.: Effect of surface roughness on friction coefficients during upsetting processes for different materials. Mater. Des. 28, 633–640 (2007). https://doi.org/10.1016/j.matdes.2005.07.019

Svahn, F., Kassman-Rudolphi, Å., Wallén, E.: The influence of surface roughness on friction and wear of machine element coatings. Wear 254, 1092–1098 (2003). https://doi.org/10.1016/S0043-1648(03)00341-7

Komvopoulos, K.: Adhesion and friction forces in microelectromechanical systems: mechanisms, measurement, surface modification techniques, and adhesion theory. J. Adhes. Sci. Technol. 17, 477–517 (2003). https://doi.org/10.1163/15685610360554384

Bowden, F.P., Tabor, D.: Mechanism of metallic friction. Nature 3798, 197–199 (1942). https://doi.org/10.1038/150197a0

Czichos, H., Habig, K.: Tribologie-Handbuch. Vieweg + Teubner, Wiesbaden (2010). ISBN 978-3-8348-0017-6

Hirano, M., Shinjo, K., Kaneko, R., Murata, Y.: Anisotropy of frictional forces in muscovite mica. Phys. Rev. Lett. 67, 2642–2646 (1991)

Dienwiebel, M., Verhoeven, G., Pradeep, N., Frenken, J., Heimberg, J., Zandbergen, H.: Superlubricity of graphite. Phys. Rev. Lett. 92, 126101 (2004). https://doi.org/10.1103/PhysRevLett.92.126101

Tomlinson, G.A.: A molecular theory of friction. Lond. Edinb. Dublin Philos. Mag. J. Sci. 7, 905–939 (1929). https://doi.org/10.1080/14786440608564819

Weiss, M., Elmer, F.: Dry friction in the Frenkel–Kontorova–Tomlinson model: static properties. Phys. Rev. B Condens. Matter 53, 7539–7549 (1996)

Etsion, I.: State of the art in laser surface texturing. J. Tribol. Trans. ASME 127, 248 (2005). https://doi.org/10.1115/1.1828070

Rapoport, L., Moshkovich, A., Perfilyev, V., Gedanken, A., Koltypin, Y., Sominski, E., Halperin, G., Etsion, I.: Wear life and adhesion of solid lubricant films on laser-textured steel surfaces. Wear 267, 1203–1207 (2009). https://doi.org/10.1016/j.wear.2009.01.053

Gachot, C., Rosenkranz, A., Reinert, L., Ramos-Moore, E., Souza, N., Müser, M.H., Mücklich, F.: Dry friction between laser-patterned surfaces: role of alignment, structural wavelength and surface chemistry. Tribol. Lett. 9, 193–202 (2013). https://doi.org/10.1007/s11249-012-0057-y

Rosenkranz, A., Reinert, L., Gachot, C., Mücklich, F.: Alignment and wear debris effects between laser-patterned steel surfaces under dry sliding conditions. Wear 318, 49–61 (2014). https://doi.org/10.1016/j.wear.2014.06.016

Sondhauß, J., Fuchs, H., Schirmeisen, A.: Frictional properties of a mesoscopic contact with engineered surface roughness. Tribol. Lett. 42, 319–324 (2011)

Persson, B.N.J.: Contact mechanics for randomly rough surfaces. Surf. Sci. Rep. 61, 201–227 (2006). https://doi.org/10.1016/j.surfrep.2006.04.001

Greenwood, J., Williamson, J.: Contact of nominally flat surfaces. R. Soc. Publ. 295, 300–319 (1966)

Jackson, R.L., Green, I.: A statistical model of elasto-plastic asperity contact between rough surfaces. Tribol. Int. 39, 906–914 (2006). https://doi.org/10.1016/j.triboint.2005.09.001

Akbulut, M.: Nanoparticle-based lubrication systems. J. Powder Metall. Min. 1, 377–411 (2012). https://doi.org/10.1002/9781118483961.ch17

Wu, Y.Y., Tsui, W.C., Liu, T.C.: Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 262, 819–825 (2007). https://doi.org/10.1016/j.wear.2006.08.021

Ivanov, M.G., Ivanov, D.M., Pavlyshko, S.V., Petrov, I., Vargas, A., McGuire, G., Shenderova, O.: Nanodiamond-based nanolubricants. Fuller. Nanotub. Carbon Nanostruct. 20, 606–610 (2012). https://doi.org/10.1080/1536383x.2012.657010

Joly-Pottuz, L., Vacher, B., Ohmae, N., Martin, J.M., Epicier, T.: Anti-wear and friction reducing mechanisms of carbon nano-onions as lubricant additives. Tribol. Lett. 30, 69–80 (2008). https://doi.org/10.1007/s11249-008-9316-3

Khalilpourazary, S., Meshkat, S.S.: Investigation of the effects of alumina nanoparticles on spur gear surface roughness and hob tool wear in hobbing process. Int. J. Adv. Manuf. Technol. 71, 1599–1610 (2014). https://doi.org/10.1007/s00170-013-5591-8

Rahmati, B., Sarhan, A.A.D., Sayuti, M.: Investigating the optimum molybdenum disulfide (MoS2) nanolubrication parameters in CNC milling of AL6061-T6 alloy. Int. J. Adv. Manuf. Technol. 70, 1143–1155 (2014). https://doi.org/10.1007/s00170-013-5334-x

Hwang, Y., Lee, C., Choi, Y., Cheong, S., Kim, D., Lee, K., Lee, J., Kim, S.H.: Effect of the size and morphology of particles dispersed in nano-oil on friction performance between rotating discs. J. Mech. Sci. Technol. 25, 2853–2857 (2011). https://doi.org/10.1007/s12206-011-0724-1

Kogovšek, J., Remškar, M., Mrzel, A., Kalin, M.: Influence of surface roughness and running-in on the lubrication of steel surfaces with oil containing MoS2 nanotubes in all lubrication regimes. Tribol. Int. 61, 40–47 (2013). https://doi.org/10.1016/j.triboint.2012.12.003

Tevet, O., Von-Huth, P., Popovitz-Biro, R., Rosentsveig, R., Wagner, H.D., Tenne, R.: Friction mechanism of individual multilayered nanoparticles. Proc. Natl. Acad. Sci. 108, 19901–19906 (2011). https://doi.org/10.1073/pnas.1106553108

Majumder, M., Rendall, C., Li, M., Behabtu, N., Eukel, J.A., Hauge, R.H., Schmidt, H.K., Pasquali, M.: Insights into the physics of spray coating of SWNT films. Chem. Eng. Sci. 65, 2000–2008 (2010). https://doi.org/10.1016/j.ces.2009.11.042

Mirri, F., Ma, A.W.K., Hsu, T.T., Behabtu, N., Eichmann, S.L., Young, C.C., Tsentalovich, D.E., Pasquali, M.: High-performance carbon nanotube transparent conductive films by scalable dip coating. ACS Nano 6, 9737–9744 (2012)

De Nicola, F., Castrucci, P., Scarselli, M., Nanni, F., Cacciotti, I., De Crescenzi, M.: Super-hydrophobic multi-walled carbon nanotube coatings for stainless steel. Nanotechnology 26, 145701 (2015). https://doi.org/10.1088/0957-4484/26/14/145701

Boccaccini, A.R., Cho, J., Roether, J.A., Thomas, B.J.C., Jane Minay, E., Shaffer, M.S.P.: Electrophoretic deposition of carbon nanotubes. Carbon 44, 3149–3160 (2006). https://doi.org/10.1016/j.carbon.2006.06.021

Besra, L., Liu, M.: A review on fundamentals and applications of electrophoretic deposition (EPD). Prog. Mater Sci. 52, 1–61 (2007). https://doi.org/10.1016/j.pmatsci.2006.07.001

Reinert, L., Zeiger, M., Suarez, S., Presser, V., Mücklich, F.: Dispersion analysis of carbon nanotubes, carbon onions, and nanodiamonds for their application as reinforcement phase in nickel metal matrix composites. RSC Adv. 5, 95149–95159 (2015). https://doi.org/10.1039/C5RA14310A

De Riccardis, M.F., Carbone, D., Rizzo, A.: A novel method for preparing and characterizing alcoholic EPD suspensions. J. Colloid Interface Sci. 307, 109–115 (2007). https://doi.org/10.1016/j.jcis.2006.10.037

Yen, B.K., Ishihara, T.: Effect of humidity on friction and wear of Al–Si eutectic alloy and Al–Si alloy-graphite composites. Wear 198, 169–175 (1996)

Savage, R.H.: Graphite lubrication. J. Appl. Phys. 19, 1 (1948). https://doi.org/10.1063/1.1697867

Berman, D., Erdemir, A., Sumant, A.V.: Graphene: a new emerging lubricant. Mater. Today 17, 31–42 (2014). https://doi.org/10.1016/j.mattod.2013.12.003

Blau, P.J.: On the nature of running-in. Tribol. Int. 38, 1007–1012 (2005). https://doi.org/10.1016/j.triboint.2005.07.020

Dogan, H., Findik, F., Morgul, O.: Friction and wear behaviour of implanted AISI 316L SS and comparison with a substrate. Mater. Des. 23, 605–610 (2002). https://doi.org/10.1016/S0261-3069(02)00066-3

Acknowledgements

The present work is supported by funding from the Deutsche Forschungsgemeinschaft (DFG, project: MU 959/38-1 and SU 911/1-1). L. R., S.S., and F. M. wish to acknowledge the EFRE Funds of the European Commission for support of activities within the AMELab project. This work was supported by the CREATe-Network Project, Horizon 2020 of the European Commission (RISE Project No. 644013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reinert, L., Schütz, S., Suárez, S. et al. Influence of Surface Roughness on the Lubrication Effect of Carbon Nanoparticle-Coated Steel Surfaces. Tribol Lett 66, 45 (2018). https://doi.org/10.1007/s11249-018-1001-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1001-6