Abstract

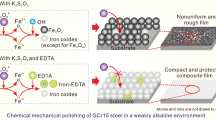

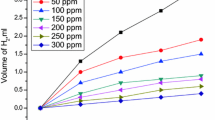

Copper chemical mechanical polishing (CMP) in barrier layer slurries with periodate as oxidant has not been intensively studied. This work presents an investigation into copper tribocorrosion in potassium periodate-based slurries during CMP. The research focused on copper tribocorrosion behavior, the surface chemical and electrochemical reaction products, and the electrochemical mechanism during CMP. The copper surface film was characterized by Raman spectra experiments. Tribocorrosion tests combined with CMP chemical experiments were conducted to study the tribochemical behavior and wear-accelerated corrosion effect. The results show that copper corrosion is more severe in acid solutions than in alkaline conditions. The copper surface is mainly passivated with copper oxides, copper hydroxide, and copper iodide. Small amounts of copper iodate, copper periodate, and iodine could be detected under specific pH conditions. Abrasion could help to get a uniform passivation film on copper surface consisting of copper oxides, copper hydroxide, and copper iodide only. The material loss due to wear-accelerated corrosion during CMP was also investigated. The results show that under weakly alkaline conditions (pH 9 and pH 10), the wear-corrosion effect plays an important role in the total material loss due to corrosion. The wear-accelerated corrosion is mainly caused by the exposure of more cathodic reaction sites to the slurry for participation in the redox reaction and the local galvanic corrosion during the CMP process. The high wear corrosion proportion of the total corrosion (ΔI c/I cc) could help to obtain a better surface quality and desirable material removal rate during CMP.

Similar content being viewed by others

References

Kim, H., Koseki, T., Ohba, T., Ohta, T., Kojima, Y., Sato, H., Shimogaki, Y.: Cu wettability and diffusion barrier property of Ru thin film for Cu metallization. J. Electrochem. Soc. 152, G594–G600 (2005)

Chan, R., Arunagiri, T.N., Zhang, Y., Chyan, O., Wallace, R.M., Kim, M.J., Hurd, T.Q.: Diffusion studies of copper on ruthenium thin film a plateable copper diffusion barrier. Electrochem. Solid-State Lett. 7, G154–G157 (2004)

Sivanandini, M., Dhami, M.K., Dhami, S.S., Pabla, B.S.: Enhancement in surface finish by modification of basic colloidal silica with silane in chemical mechanical polishing. ECS J. Solid State Sci. Technol. 3, P324–P329 (2014)

Hartmannsgruber, E., Zwicker, G., Beekmann, K.: A selective CMP process for stacked low-k CVD oxide films. Microelectron. Eng. 50, 53–58 (2000)

Hung, C., Wang, Y., Lee, W., Chang, S., Wang, Y.: Galvanic corrosion between TaNx barriers and copper seed. Electrochem. Solid-State Lett. 10, H127–H130 (2007)

Wu, C., Lee, W., Chang, S., Wang, Y.: Investigation of the galvanic effect between RuN barriers and Cu seed Layers. Jpn. J. Appl. Phys. 50, 1803 (2011)

Zeng, X., Wang, J., Lu, H., Chen, F., Zhang, X., Qu, X.: Improved removal selectivity of ruthenium and copper by glycine in potassium periodate (KIO4)-based slurry. J. Electrochem. Soc. 159, C525–C529 (2012)

Peethala, B.C., Babu, S.V.: Ruthenium polishing using potassium periodate as the oxidizer and silica abrasives. J. Electrochem. Soc. 158, H271–H276 (2011)

Wu, C., Wang, Y., Lee, W.: Copper electrodeposition on Ru-N barrier with various nitrogen content for 22 nm semiconductor manufacturing application. J. Electrochem. Soc. 159, D684–D689 (2012)

Qu, X., Tan, J., Zhou, M., Chen, T., Xie, Q., Ru, G., Li, B.Z.: Improved barrier properties of ultrathin Ru film with TaN interlayer for copper metallization. Appl. Phys. Lett. 88, 151912 (2006)

Chyan, O., Arunagiri, T.N., Ponnuswamy, T.: Electrodeposition of copper thin film on ruthenium a potential diffusion barrier for Cu interconnects. J. Electrochem. Soc. 150, C347–C350 (2003)

Cui, H., Park, J., Park, J.: Corrosion inhibitors in sodium periodate slurry for chemical mechanical planarization of ruthenium film. ECS J. Solid State Sci. Technol. 2, P71–P75 (2013)

Cui, H., Park, J., Park, J.: Study of ruthenium oxides species on ruthenium chemical mechanical planarization using periodate-based slurry. J. Electrochem. Soc. 159, H335–H341 (2012)

Lee, W., Park, H.: Development of novel process for Ru CMP using ceric ammonium nitrate (CAN)-containing nitric acid. Appl. Surf. Sci. 228, 410–417 (2004)

Victoria, S.N., Sharma, P.P., Suni, I.I., Ramanathan, S.: Potassium bromate as an oxidizing agent in a titania-based Ru CMP slurry. Electrochem. Solid-State Lett. 13, H385–H387 (2010)

Kim, I., Kang, Y., Kwon, T., Cho, B., Park, J., Park, J., Park, H.: Effect of sodium periodate in alumina-based slurry on Ru CMP for metal-insulator-metal capacitor. Electrochem. Solid-State Lett. 11, H150–H153 (2008)

Peethala, B.C., Roy, D., Babu, S.V.: Controlling the galvanic corrosion of copper during chemical mechanical planarization of ruthenium barrier films. Electrochem. Solid-State Lett. 14, H306–H310 (2011)

Jiang, L., He, Y., Niu, X., Li, Y., Luo, J.: Synergetic effect of benzotriazole and non-ionic surfactant on copper chemical mechanical polishing in KIO4-based slurries. Thin Solid Films 558, 272–278 (2014). doi:10.1016/j.tsf.2014.01.086

Chockalingam, A.M., Lagudu, U.R.K., Babu, S.V.: Potassium periodate-based solutions for minimizing galvanic corrosion at the Cu-Mn interface and for polishing the associated Cu interconnect structures. ECS J. Solid State Sci. Technol. 2, P160–P165 (2013)

Jiang, J., Stack, M.M., Neville, A.: Modelling the tribo-corrosion interaction in aqueous sliding conditions. Tribol. Int. 35, 669–679 (2002)

Vieira, A.C., Rocha, L.A., Papageorgiou, N., Mischler, S.: Mechanical and electrochemical deterioration mechanisms in the tribocorrosion of Al alloys in NaCl and in NaNO3 solutions. Corros. Sci. 54, 26–35 (2012)

Stojadinovic, J., Bouvet, D., Declercq, M., Mischler, S.: Influence of chelating agents on the tribocorrosion of tungsten in sulphuric acid solution. Electrochim. Acta 56, 7131–7140 (2011)

Li, J., Chai, Z., Liu, Y., Lu, X.: Tribo-chemical behavior of copper in chemical mechanical planarization. Tribol. Lett. 50, 177–184 (2013)

Stojadinović, J., Mendia, L., Bouvet, D., Declercq, M., Mischler, S.: Electrochemically controlled wear transitions in the tribocorrosion of ruthenium. Wear 267, 186–194 (2009)

Hernandez, J., Wrschka, P., Oehrlein, G.S.: Surface chemistry studies of copper chemical mechanical planarization. J. Electrochem. Soc. 148, G389–G397 (2001)

Cano, E., López, M.F., Simancas, J., Bastidas, J.M.: X-ray photoelectron spectroscopy study on the chemical composition of copper tarnish products formed at low humidities. J. Electrochem. Soc. 148, E26–E30 (2001)

Melendres, C.A., Bowmaker, G.A., Leger, J.M., Beden, B.: In-situ synchrotron far infrared spectroscopy of surface films on a copper electrode in aqueous solutions. J. Electroanal. Chem. 449, 215–218 (1998)

Li, Y., Babu, S.V.: Chemical mechanical polishing of copper and tantalum in potassium iodate-based slurries. Electrochem. Solid-State Lett. 4, G20–G22 (2001)

Luo, Q.: Copper dissolution behavior in acidic iodate solutions. Langmuir 16, 5154–5158 (2000)

Anik, M.: Selection of an oxidant for copper chemical mechanical polishing: copper-iodate system. J. Appl. Electrochem. 35, 1–7 (2005)

Näsänen, R.: Studies on copper (II) periodates. Acta Chem. Scand. 8, 1587–1592 (1954)

Deplano, P., Devillanova, F.A., Ferraro, J.R., Isaia, F., Lippolis, V., Mercuri, M.L.: On the use of Raman spectroscopy in the characterization of iodine in charge-transfer complexes. Appl. Spectrosc. 46, 1625–1629 (1992)

Klaeboe, P.: The Raman spectra of some iodine, bromine, and iodine monochloride charge-transfer coomplexes in solution. J. Am. Chem. Soc. 89, 3667–3676 (1967)

Wu, Z., Zhang, Z., Liu, L.: Electrochemical studies of a Cu (II)-Cu (III) couple: cyclic voltammetry and chronoamperometry in a strong alkaline medium and in the presence of periodate anions. Electrochim. Acta 42, 2719–2723 (1997)

Zhou, Y., Xu, F., Mo, X., Ye, F.: Calorimetric studies for the dissolution of orthoperiodate salt of the type: M2HIO6·nH2O (M = Cu2+, Zn2+, Cd2+). Thermochim. Acta 398, 23–26 (2003). doi:10.1016/S0040-6031(02)00361-1

Kiefer, W.: Recent advances in linear and non-linear Raman spectroscopy. Part III+. J. Raman Spectrosc. 40, 1766–1779 (2009)

Li, J., Liu, Y., Lu, X., Luo, J., Dai, Y.: Material removal mechanism of copper CMP from a chemical-mechanical synergy perspective. Tribol. Lett. 49, 11–19 (2013)

Hamilton, J.C., Farmer, J.C., Anderson, R.J.: In situ Raman spectroscopy of anodic films formed on copper and silver in sodium hydroxide solution. J. Electrochem. Soc. 133, 739–745 (1986)

Niaura, G.: Surface-enhanced Raman spectroscopic observation of two kinds of adsorbed OH− ions at copper electrode. Electrochim. Acta 45, 3507–3519 (2000)

Texier, F., Servant, L., Bruneel, J.L., Argoul, F.: In situ probing of interfacial processes in the electrodeposition of copper by confocal Raman microspectroscopy. J. Electroanal. Chem. 446, 189–203 (1998)

Persson, D., Leygraf, C.: In situ infrared reflection absorption spectroscopy for studies of atmospheric corrosion. J. Electrochem. Soc. 140, 1256–1260 (1993)

Kliche, G., Popovic, Z.V.: Far-infrared spectroscopic investigations on CuO. Phys. Rev. B 42, 10060 (1990)

Biton, M., Salitra, G., Aurbach, D., Mishkov, P., Ilzycer, D.: On the electrochemical behavior and passivation of copper and brass (Cu70/Zn30) electrodes in concentrated aqueous KOH solutions. J. Electrochem. Soc. 153, B555–B565 (2006)

Irish, D.E., Stolberg, L., Shoesmith, D.W.: Surface enhanced Raman spectroscopy and electrochemistry at the copper/iodide, water interface. Surf. Sci. 158, 238–253 (1985)

Anderson, A., Sun, T.S.: Raman spectra of molecular crystals I. Chlorine, bromine, and iodine. Chem. Phys. Lett. 6, 611–616 (1970)

Nassau, K., Shiever, J.W., Prescott, B.E.: Transition metal iodates. I. Preparation and characterization of the 3d iodates. J. Solid State Chem. 7, 186–204 (1973)

Botova, M., Nagel, R., Haeuseler, H.: Präparation, kristallstruktur, schwingungsspektren und thermische analyse von kupfer-tetrahydrogen-decaoxo-diperiodat-hexahydrat CuH4I2O10·6H2O. Zeitschrift für anorganische und allgemeine Chemie 630, 179–184 (2004)

Zhang, X.L., Jiang, Z.H., Yao, Z.P., Song, Y., Wu, Z.D.: Effects of scan rate on the potentiodynamic polarization curve obtained to determine the Tafel slopes and corrosion current density. Corros. Sci. 51, 581–587 (2009)

Deltombe, E., De Zoubov, N., Pourbaix, M.: Atlas of electrochemical equilibria in aqueous solutions. Pergamon Press, Oxford (1966)

Wang, M.T., Tsai, M.S., Liu, C., Tseng, W.T., Chang, T.C., Chen, L.J., Chen, M.C.: Effects of corrosion environments on the surface finishing of copper chemical mechanical polishing. Thin Solid Films 308–309, 518–522 (1997). doi:10.1016/S0040-6090(97)00500-2

Varadarajan, T.K., Ramakrishna, T.V., Kalidas, C.: Ion solvation of some copper (II) salts in water + N-Methyl-2-pyrrolidinone solvent mixtures at 30° C. J. Chem. Eng. Data 42, 453–457 (1997)

Landolt, D.: Corrosion and surface chemistry of metals. CRC Press, Lausanne (2007)

Mischler, S., Spiegel, A., Landolt, D.: The role of passive oxide films on the degradation of steel in tribocorrosion systems. Wear 225, 1078–1087 (1999)

Mindivan, H., Baydogan, M., Kayali, E.S., Cimenoglu, H.: Wear behaviour of 7039 aluminum alloy. Mater. Charact. 54, 263–269 (2005)

Li, J., Liu, Y., Wang, T., Lu, X., Luo, J.: Electrochemical investigation of copper passivation kinetics and its application to low-pressure CMP modeling. Appl. Surf. Sci. 265, 764–770 (2013)

Acknowledgment

The authors greatly appreciate the financial support of the Science Fund for Creative Research Groups (51321092), National Natural Science Foundation of China (51205226, 91323302), and National Basic Research Program of China (2015CB057203).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, J., Wang, T., Chai, Z. et al. Tribocorrosion Study of Copper During Chemical Mechanical Polishing in Potassium Periodate-Based Slurry. Tribol Lett 58, 8 (2015). https://doi.org/10.1007/s11249-015-0474-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0474-9