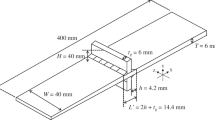

The study aimed to determine the nature of the influence of the results of surface layer nitriding on the endurance characteristics of titanium alloy VT1-0. The factor of such a problem statement is the need to strengthen parts and structural elements by their surface modification. The effectiveness of the strengthening technology was checked on the example of fatigue bending load. Preliminary modification of the surface layer of the material specimens was performed using diffusion ion-plasma thermocyclic nitriding (IPTA) technology, the variable parameters of which were pressure, the temperature in the working chamber, and the duration of the diffusion process. To experimentally determine the effect of modification parameters on endurance to conduct experiments in real time, a high-frequency method for determining the endurance limits was used. As one of the most effective methods of accelerated determination of the endurance limit, this method is the most convenient for comparative studies of the fatigue strength of materials. A high-frequency magnetostrictive installation was used. To determine the endurance limit σ–1 under symmetric bending loading, cantilever prismatic specimens were tested by excitation of resonant bending vibrations at a frequency of 11–12 kHz. To ensure fatigue failure of the specimens in a predetermined cross-section, remote from the place of fixing on the installation, a variant of point-hinged fixing of the cantilever specimen was used, in which intense resonant vibrations with two nodal cross-sections were excited. Fatigue failure under such a loading scheme occurs in an entirely determined section between two nodes of oscillations. Calculating the destructive stresses in this section is performed by a method based on measuring the vibration frequency and coordinates of the nodal sections. Fatigue tests of five groups of specimens were carried out – one with specimens in the state of delivery without technological processing and four groups after technological modification of the surface layer. Fatigue curves were built based on 107 loading cycles. It was found that regardless of the variation of IPTA technology parameters in their given range, the endurance limits σ–1 of titanium with a modified surface are higher by 12–17% compared to σ–1 for unmodified titanium VT1-0. From the analysis of the correlation between the obtained values of σ–1 and the corresponding technological parameters of nitriding, as well as based on the visual coincidence of fatigue curves for the number of cycles exceeding 3×106, where the failure is mainly fatigue, it is assumed that it is possible to guarantee the hardening of the VT1-0 alloy in the selected range of technological parameters, regardless of their variation in this interval. For practice, this means a high probability of repetition of the strengthening effect and its stability as a result of nitriding by this technology, which will thus provide an increase in endurance even with possible deviations of the relevant parameters – pressure, temperature, diffusion process time.

Similar content being viewed by others

References

N. V. Novikov, A. A. Bidnyi, and B. A. Lyashenko, Methods of Surface Hardening of Machine-Building Parts [in Russian], Institute for Superhard Materials of the National Academy of Sciences of Ukraine, Kiev (1989).

A. G. Trapezon, B. A. Lyashenko, and M. O. Lysenkov, “Fatigue strength of metals with hardening coatings (review),” Strength Mater., 45, No. 3, 284‒294 (2013). https://doi.org/10.1007/s11223-013-9457-y

A. N. Petukhov, Fatigue Resistance of GTE Parts [in Russian], Mashinostroenie, Moscow (1993).

A. G. Trapezon, B. A. Lyashenko, and A. V. Rutkovskii, “Effect of vacuum deposited coatings on the fatigue strength of commercial-grade titanium,” Strength Mater., 27, Nos. 11–12, 659‒664 (1995). https://doi.org/10.1007/BF02206239

B. A. Lyashenko, A. G. Trapezon, and A. V. Rutkovskii, “Vacuum-plasma coatings as a reserve for increasing the fatigue resistance of sheet materials,” Vibr. Tekhn. Tekhnol., 21, No. 5, 76–79 (2001).

A. G. Trapezon, B. A. Lyashenko, and N. V. Lipinskaya, “Fatigue of VT20 titanium alloy with vacuum-plasma coatings at high temperatures,” Strength Mater., 41, No. 4, 417‒422 (2009). https://doi.org/10.1007/s11223-009-9138-z

Y. Su, S. Yao, and C. Wei, “Influence of single- and multilayer TiN films on the axial tension and fatigue performance of ANSI 1045 steel,” Thin Solid Films, 338, Nos. 1–2, 177‒184 (1999).

A. G. Molyar and A. I. Vasiliev, “Influence of ion-plasma coatings on fatigue strength of a material,” Aviats. Promyshl., 37, No. 8 (1994).

S. Das, S. Guha, R. Ghadai, et al., “Structural and mechanical properties of CVD deposited titanium aluminum nitride (TiAlN) thin films,” Appl. Phys. A, 123, 412 (2017).

X. Xing, H. Wang, T. Jin, et al., “Scratch and wear behaviours of metallised Ti thin films deposited on Al2O3 substrate,” Appl. Phys. A, 124, 718 (2018).

E. Vetrivendan and J. Jayaraj, “Argon shrouded plasma spraying of tantalum over titanium for corrosion protection in fluorinated nitric acid media,” J. Therm. Spray Techn., 27, 512‒523 (2018).

J. Fathi and S. Mohsenian, “Plasma spray deposition enhancement of titanium nitride layer using nitrogencontained plasma irradiation of titanium substrate as a pre-spraying method,” J. Therm. Spray Techn., 27, 1187‒1193 (2018).

R. Ahmed, O. Ali, and C. Berndt, “Sliding wear of conventional and suspension sprayed nanocomposite WCCo coatings: an invited review,” J. Therm. Spray Techn., 30, 800‒861 (2021).

M. Eshaghpour, I. Ebrahimzadeh, and M. Rafiei, “Enhanced surface properties of plain carbon steel by duplex process of friction stir processing and plasma nitriding,” J. Mater. Eng. Perform., 30, 2991‒3002 (2021).

Z. Peng and H. Zhao, “Corrosion mechanism of a plasma nitriding-treated alloy,” Strength Mater., 53, No. 1, 83‒87 (2021). https://doi.org/10.1007/s11223-021-00263-5

E. Zdravecká, J. Slota, P. Solfronk, and M. Kolnerová, “Evaluation of the effect of different plasma-nitriding parameters on the properties of low-alloy steel,” J. Mater. Eng. Perform., 26, No. 7, 3588‒3596 (2017).

I. Pohrelyuk, S. Lavrys, O. Sakharuk, and I. Stasyshyn, “Pretreatment influence on titanium surface properties after gas nitriding,” J. Mater. Eng. Perform., 26, 5072‒5078 (2017).

A. G. Trapezon, “A method of fatigue testing of thin-sheet materials in plane bending at high loading frequencies,” Strength Mater., 9, No. 3, 283‒287 (1977). https://doi.org/10.1007/BF01532480

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 6, pp. 67 – 75, November – December, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kalinichenko, V.I., Trapezon, O.G. & Rutkovskyi, A.V. Determination of Fatigue Strength of VT1-0 Titanium Sheet Under Cyclic Bending On Prismatic Specimens With Surface Layer Modification. Strength Mater 54, 1027–1034 (2022). https://doi.org/10.1007/s11223-023-00477-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-023-00477-9