Abstract

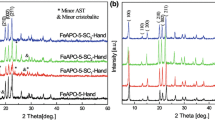

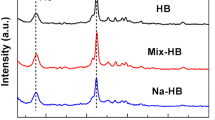

A modified solvent-free method has been developed to synthesize FeAPO-5 zeolite catalysts with hierarchical porous structure as well as high crystallinity and iron content. The effects of mechanochemical and low-temperature pretreatment, as well as the addition of hydrogen peroxide and seed crystals on the synthesis of FeAPO-5 were studied in detail. The composition and structural features of relatively pure resultant products were deeply analyzed by XRD, SEM, ICP-AES, CHN analysis, TG–DTA, UV–Vis diffuse reflectance spectroscopy and N2 physisorption. Most importantly, low-temperature pretreatment towards H2O2-containing precursor mixtures can to a great degree improve the crystallinity of FeAPO-5 molecular sieve. Significantly, compared to the conventional micron-sized microporous FeAPO-5 zeolite, the hierarchical FeAPO-5 catalysts created by this modified solvent-free method show superior performance in phenol hydroxylation, in which the one with a high content of framework iron species exhibits the best catalytic performance, giving phenol conversion of about 40% and dihydroxybenzene selectivity of up to 80% at 50 °C within 3 h reaction time.

Similar content being viewed by others

References

Wilson ST, Lok BMT, Messina CA, Cannan TR, Flanigen EM (1982) J Am Chem Soc 104:1146–1147

Flanigen EM, Lok BMT, Patton RL, Wilson ST (1986) Pure Appl Chem 58:1351–1358

Corma A (1997) Chem Rev 97:2373–2419

Davis ME (2014) Chem Mater 26:239–245

Davis ME, Saldarriaga C, Montes C, Garces JM, Crowdert C (1988) Nature 331:698–699

Davis ME (2002) Nature 417:813–821

Miller SJ (1994) Microporous Mater 2:439–449

Feng P, Bu X, Stucky GD (1997) Nature 388:735–741

Bibby DM, Dale MP (1985) Nature 317:157–158

Morris RE, Weigel SJ (1997) Chem Soc Rev 28:309–317

Cooper ER, Andrews CD, Wheatley PS, Webb PB, Wormald P, Morris RE (2004) Nature 430:1012–1016

Wu Q (2012) Yinying, Ren L, Meng X, Xiao FS. J Am Chem Soc 134:15173–15176

Jin Y, Sun Q, Qi G, Yang C, Xu J, Chen F, Meng X, Deng F, Xiao FS (2013) Angew Chem Int Ed 52:9172–9175

Sheng N, Chu Y, Xin S, Wang Q, Yi X, Feng Z, Meng X, Liu X, Deng F, Xiao FS (2016) J Am Chem Soc 138:6171–6176

Jin Y, Chen X, Sun Q, Sheng N, Liu Y, Bian C, Chen F, Meng X, Xiao FS (2014) Chem Eur J 20:17616–17623

Zhao X, Zhao J, Wen J, An L, Li G, Wang X (2015) Microporous Mesoporous Mater 213:192–196

Zhao X, Zhao J, Gao X, Zhao Y (2015) RSC Adv 5:95690–95694

Zhao X, Gao X, Zhang X, Hao Z (2017) Microporous Mesoporous Mater 242:160–165

Iida T, Sato M, Numako C, Nakahira A, Kohara S, Okubo T, Wakihara T (2015) J Mater Chem A 3:6215–6222

Mintova S, Gilson JP, Valtchev V (2013) Nanoscale 5:6693–6703

Feng G, Cheng P, Yan W, Boronat M, Li X, Su JH, Wang J, Li Y, Corma A, Xu R (2016) Science 351:6

Iyoki K, Itabashi K, Okubo T (2014) Microporous Mesoporous Mater 189:22–30

Catana G, Pelgrims J, Schoonheydt RA (1995) Zeolites 15:475–480

Utchariyajit K, Wongkasemjit S (2010) Microporous Mesoporous Mater 135:116–123

Auerbach SM, Carrado KA, Dutta PK (2003) Handbook of zeolite science and technology. Marcel Dekker, New York

Samanta S, Giri S, Sastry PU, Mal NK, Manna A, Bhaumik A (2003) Ind Eng Chem Res 42:3012–3018

Li Y, Feng Z, Lian Y, Sun K, Zhang L, Jia G, Yang Q, Li C (2005) Microporous Mesoporous Mater 84:41–49

Li LD, Shen Q, Yu JJ, Hao ZP, Xu ZP, Lu GQM (2007) Environ Sci Technol 41:7901–7906

Kumar MS, Schwidder M, Grünert W, Brückner A (2004) J Catal 227:384–397

Choi JS, Yoon SS, Jang SH, Ahn WS (2006) Catal Today 111:280–287

Wang J, Xu J, Li B, Zhang G, Wu N, Mao L (2014) Mater Lett 124:54–56

Kosri C, Deekamwong K, Sophiphun O, Osakoo N, Chanlek N, Föttinger K, Wittayakun J (2017) React Kinet Mech Catal 121:751–761

Preethi MEL, Revathi S, Sivakumar T, Manikandan D, Divakar D, Rupa AV, Palanichami M (2008) Catal Lett 120:56–64

Adam F, Wong JT, Ng EP (2013) Chem Eng J 214:63–67

Mohamed MM, Eissa NA (2003) Mater Res Bull 38:1993–2007

Zhao X, Sun Z, Zhu Z, Li A, Li G, Wang X (2013) Catal Lett 143:657–665

Chellal K, Bachari K, Sadi F (2014) J Cluster Sci 25:523–539

Liu C, Shan Y, Yang X, Ye X, Yue W (1997) J Catal 168:35–41

Khodadadi Z, Mahmoudian R (2016) React Kinet Mech Catal 119:685–697

Kamegawa T, Ando T, Ishiguro Y, Yamashita H (2015) Bull Chem Soc Jpn 88:572–574

Jin M, Yang R, Zhao M, Li G, Hu C (2014) Ind Eng Chem Res 53:2932–2939

Li B, Wu K, Yuan T, Han C, Xu J, Pang X (2012) Microporous Mesoporous Mater 151:277–281

Xin H, Liu J, Fan F, Feng Z, Jia G, Yang Q, Li C (2008) Microporous Mesoporous Mater 113:231–239

Liu H, Lu G, Guo Y, Guo Y, Wang J (2008) Microporous Mesoporous Mater 108:56–64

Li B, Xu J, Liu J, Pan Z, Wu Z, Zhou Z, Pang X (2012) Mater Lett 78:147–149

Zhao X, Zhang X, Hao Z, Gao X, Liu Z (2018) J Porous Mater 25:1007–1016

Wu C, Kong Y, Gao F, Wu Y, Lu Y, Wang J, Dong L (2008) Microporous Mesoporous Mater 113:163–170

Jhung SH, Chang JS, Hwang YK, Park SE (2004) J Mater Chem 14:280–285

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 21306072 and 21666019) and the Natural Science Foundation of Gansu Province, China (Grant No. 17JR5RA124). We cordially thank the Reviewers and Editors for providing us with valuable comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhao, X., Duan, W., Zhang, X. et al. Insights into the effects of modifying factors on the solvent-free synthesis of FeAPO-5 catalysts towards phenol hydroxylation. Reac Kinet Mech Cat 125, 1055–1070 (2018). https://doi.org/10.1007/s11144-018-1465-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-018-1465-2