ABSTRACT

Purpose

Intradermal immunization using microneedles requires compatible immunoadjuvant system. To address this challenge, we investigated microneedles coated with polyphosphazene polyelectrolyte, which served both as microfabrication material and an immunoadjuvant compound.

Methods

Coated microneedles were fabricated by depositing formulations containing Poly[di(carboxylatophenoxy)phosphazene], PCPP, on metal shafts, and their physico-chemical characterization was conducted.

Results

Microfabrication of PCPP-coated microneedles exhibited strong dependence on protein-PCPP interactions in solutions and allowed for high efficiency of protein encapsulation. 70°C thermal inactivation studies demonstrated a remarkable increase in functional stability of protein in coated microneedles compared to solution formulation. A potential for modulation of protein release from coated microneedles has been demonstrated through ionic complexation of PCPP with small ions.

Conclusions

Microneedles containing PCPP coatings provide improved protein stability, modulated release, and protein-friendly microfabrication process.

Similar content being viewed by others

INTRODUCTION

Delivery of antigenic molecules into dermal and epidermal compartments of the skin has been of significant interest for the purpose of vaccine development (1–4). The skin, as an organ that is constantly exposed to external antigens, is richly populated by professional antigen-processing and -presenting cells, such as Langerhan’s cells of the epidermis and dermal dendritic cells (5). The unique antigen-presenting function of these cells is thought to facilitate induction of more potent immune responses and provide the basis for a significant antigen-sparing effect compared to intramuscular immunization (1–4). However, technical realization of intradermal vaccination faces significant challenges, and the approach can benefit greatly from the deployment of advanced intradermal delivery technologies (6,7).

Coated microneedles containing solid formulations represent an important type of delivery system suitable for such application (7). They are designed to incorporate vaccine inside a biologically inactive material, which constitutes an outer layer of the device, whereas a metal shaft provides structural support (7). Water-soluble bioinert polymer is frequently employed as a key construction material for the coating imparting required mechanical properties and enabling almost instantaneous dissolution in aqueous environment for the release of vaccine.

Despite the attractiveness and apparent simplicity of the approach, it faces considerable difficulties in its practical implementation. One of them is the lack of compatibility with many existing vaccine adjuvant systems, a crucial component of contemporary vaccines (8). Alum, the most common adjuvant used in the vaccine market globally (8), has been shown to induce serious adverse effects when administered intradermally (9). Other advanced adjuvants, which contain biphasic systems, such as oil emulsions or liposomes, may not be sufficiently stable to withstand the microneedle coating and drying processes.

Recently, we reported microneedles with integrated immunoadjuvant properties, in which polyphosphazene compound served both as a coating agent and a potent immunostimulant (10). Polyphosphazenes, synthetic macromolecules with phosphorus-nitrogen backbone and organic side groups, represent an increasingly important class of biomedical polymers (11). In particular, Poly[di(carboxylatophenoxy)phosphazene], PCPP (Fig. 1), a water-soluble ionic representative of this family, has been extensively studied as a potent immunoadjuvant (12). When used for intradermal delivery of hepatitis B surface antigen, PCPP-coated microneedles demonstrated superior performance in pigs compared to intramascular injections, as well as a significant antigen-sparing effect (10). PCPP-based microneedle formulations also induced dramatically higher antibody titers than similar systems coated with bioinert polymer, sodium carboxymethylcellulose (CMC). As a coating agent, PCPP accelerated formation of solid-state formulations compared to CMC when used in surfactant-free or low surfactant content formulations (10).

The present paper investigates polyphosphazene microneedle coating process focusing on its correlation with solution behavior of PCPP formulations, such as protein-polymer complex formation and effects of surfactant and ionic strength. It also studies the ability of protein to withstand microfabrication process and its thermal stability in coated microneedles. Finally, it establishes the approach in which ion-complexing properties of PCPP are exploited with a goal of modulating protein release from microneedles.

METHODS AND MATERIALS

Materials

Poly[di(carboxylatophenoxy)phosphazene], sodium salt, PCPP (Aldrich, St. Louis, MO) was purified by multiple precipitations using sodium chloride (13) to produce polymer with weight-average molecular weight of 855,000 g/mol and polydispersity parameter of 2.5, as determined by gel permeation chromatography using poly(acrylic acid) standards. Sodium carboxymethylcellulose (USP/NF grade, low viscosity), CMC (Hercules, Wilmington, DE); calcium chloride dihydrate (Mallinckrodt Baker, Phillipsburg, NJ); sodium chloride (EMD Chemicals, Gibbstown, NJ); spermine tetrahydrochloride; sodium phosphate dibasic heptahydrate; sodium phosphate monobasic; potassium phosphate monobasic; albumin from bovine serum, BSA; albumin–fluorescein isothiocyanate conjugate albumin bovine, FITC-BSA (Sigma, St, Louis, MO), Horseradish Peroxidase, HRP (Pierce, Rockford, IL); polyoxyethylene (20) sorbitan monolaurate, Tween-20 (TCI America, Portland, OR) were purchased commercially. 1× Dulbecco’s Phosphate-Buffered Saline, PBS, (Lonza, Walkersville, MD) was used as received. Phosphate buffers were prepared by mixing sodium phosphate dibasic and sodium phosphate monobasic, and buffer strength was calculated as a sum of their molar concentrations.

Microneedle Fabrication and Analysis

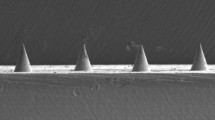

Microneedle arrays were produced in a two-stage process. First, arrays of 50 metal shafts were manufactured by chemical etching of titanium foil using hydrofluoric acid and bent out of plane at a 90° angle. The design was similar to previously reported stainless steel microneedles (14,15). Each shaft was 600 µm long, and the arrays had dimensions of 1 × 1 cm. Next, a micro-dipcoating process was performed at ambient temperature to coat the tips of these shafts with PCPP-protein formulation to fabricate microneedles. The coating formulation was fed to a 50 micro-well reservoir using a Genie Plus syringe pump (Kent Scientific, Torrington, CT). A microneedle array was secured on an array holder and then attached to an X-Y-Z micro-positioning system using alignment pins and holders. Using the micro-positioning system, the coating procedure was performed for all compositions by submerging the shafts into the wells in the coating reservoir and then immediately removing them, allowing contact between microneedle and formulation for no longer than 1 s. Each submersion was followed by a drying step in which the arrays were purged with anhydrous nitrogen gas for 7 s. A stereo zoom microscope (STZ-45-BS-FR) with a digital camera (Caltex Scientific, Irvine, CA) was used to monitor the process.

Quantitative analysis of the coating was performed using UV/Vis Spectrophotometry (HITACHI U-2810 Spectrophotomer, Hitachi, San Jose, CA) and size exclusion high performance liquid chromatography (HPLC) (Hitachi LaChrom Elite system, Hitachi, San Jose, CA) equipped with Ultrahydrogel 250 size exclusion column (Waters Corporation, Milford, MA) using 0.1× PBS with 10% acetonitrile as a mobile phase. Each coated array was placed in an individual plastic weigh boat, along with 1 mL of 0.1× PBS to dissolve the coating. Analysis of protein loading using 12 arrays with the same target dose revealed the variability of the coating method to constitute ±8%.

The kinematic viscosity of formulations was measured at 25°C using the calibrated Cannon-Manning Semi-Micro Viscometer (CANNON Instrument Company, State College, PA).

Coating Formulations

Coating formulations were prepared by mixing stock solutions of the components and gently vortexing the resulting formulations at ambient temperature. The following formulations were prepared: macromolecular interaction studies (0.5% PCPP, 1.0% BSA, 0.005 M phosphate buffer, pH 7.4), buffer strength studies (0.5% PCPP, 1.0% BSA in 0.005 M, 0.010 M, or 0.050 M phosphate buffer, pH 7.4), effect of surfactant studies (0.5% PCPP or 1.0% CMC, 1.0% BSA, with or without 0.1% Tween, 0.005 M phosphate buffer, pH 7.4), HRP encapsulation and stability experiments (1.0% PCPP, 0.5% HRP, 0.1% Tween, 0.5× PBS, pH 7.4), BSA release studies (1.0% PCPP, 0.3% FITC-BSA, 0.1% Tween, 0.5× PBS, pH 7.4).

Protein Stability

Protein stability in a microencapsulation process and in a solid coating was assessed by dissolving the coating as described above and evaluating enzymatic activity of HRP, which was normalized by weight as determined by HPLC and compared to its activity in the formulation solution or in other coatings. Enzymatic activity of HRP was determined using 2,2′-azino-bis(3-ethylbenzthiazoline-6-sulfonic acid) as a substrate (16) by measuring UV absorbance at 405 nm (UV/Vis Spectrophotometer, HITACHI U-2810, Hitachi, San Jose, CA). Maximum linear rate ΔA405nm/minute was used to calculate the activity (Enzymatic assay of peroxidase from horseradish, EC 1.11.1.7, Sigma Prod. No. P-6782).

Protein Release

PCPP coatings were fabricated according to the procedure described above to contain 40 µg/array of PCPP and 10 µg/array of FITC-BSA. Cross-linking with calcium chloride was performed by first placing the arrays in individual plastic weigh boats along with 0.5 mL of 5% (w/v) calcium chloride and 10% (w/v) sodium chloride in deionized water. After 10 min, they were removed from solution and dried with anhydrous nitrogen for 1 min and then left in a desiccator overnight. Cross-linking with calcium chloride and spermine, a two-step procedure, was also employed by (1) cross-linking with calcium chloride and sodium chloride as described above, followed by (2) cross-linking with spermine and sodium chloride (0.5 mL of 2% (w/v) of spermine tetrachloride and 10% (w/v) of sodium chloride in deionized water). The arrays were kept in the solution for 2 min and then dried as described above.

A release study was performed under ambient conditions, with the arrays in 0.5 mL of 0.9% sodium chloride in water. The solution was refreshed after each time point was taken. The amount of FITC-BSA and PCPP released from the microneedles was analyzed via UV–Vis spectrophotometry by obtaining the optical densities at 495 nm and 235 nm.

RESULTS AND DISCUSSION

Microneedles Containing Polyphosphazene Formulations as Coatings

Polyphosphazene microneedles were designed to encompass a metal shaft for structural support and a solid protein-polymer formulation coated on its external surface (Fig. 1). PCPP, a water-soluble polyphosphazene polyelectrolyte, which possesses potent immunoadjuvant properties (12), was used as a key coating agent (Fig. 1). Arrays, each including 50 microneedles, were prepared in a two-step process. First, metal shafts were produced by chemical etching of titanium foil and bent out of plane at a 90° angle. Each shaft was 600 µm long, and the arrays had dimensions of 1 × 1 cm. A micro-dipcoating process was then used to coat the tips of these shafts with a solution containing PCPP and protein. Procedure involved the use of a reservoir, which comprised individual microwells corresponding to each shaft on the array and was carried out by contacting the shafts with the formulation in the reservoir (14,15). Such dipping-drying coating cycles were repeated as needed to produce the desired dose of the material in the microneedle. In general, end points for the formation of microneedle coatings are defined by the doses of protein and PCPP and vary according to the application. The end point of the coating process can be identified volumetrically by dosing the amount of the formulation supplied to a microneedle array as described previously (10).

Effect of Macromolecular Interactions in the Formulation on the Coating Process

Coating process is a key component of microfabrication technology as functional properties of microneedles, including their biological activity, are essentially defined at this stage. Its efficiency and controllability, in turn, largely depend on physico-chemical characteristics of formulation solutions, such as viscosity and surface tension (15). Macromolecular interactions between formulation components in solutions can play an important role in determining solution properties and thus affect the coating process (10). For example, the effect of protein-polymer complexation has been reported to cause drastically different coating formation efficiencies for polymers possessing similar viscosity-enhancing characteristics (10). PCPP has been shown to display solution characteristics, which can diverge from those of other polyelectrolytes, especially in regards to interactions with proteins and small ions (13,17–19). Thus, understanding of solution behavior of PCPP formulations, specifically polymer-protein complexation, and effects of ionic strength and surfactant is imperative for controlling microneedle properties.

Microneedle coating process has been studied as a function of a number of coating cycles using solutions of PCPP, BSA, and a mixture of PCPP-BSA (Fig. 2). Remarkably, coating formation was dramatically faster for PCPP-BSA mixture than for its components, including PCPP (Fig. 2). Moreover, the viscosity of PCPP-BSA formulations was strongly affected by the protein content (Fig. 3). In fact, solutions containing 1% BSA and PCPP were at least twice as viscous as protein-free polymer solution. As expected, in the absence of PCPP, protein did not increase the viscosity of solution in the range of concentrations used. This suggests formation of PCPP-BSA complexes, similar to that described previously (17), resulting in a higher formulation viscosity and leading to a faster coating build-up. These results also support previous findings on a superior coating performance of PCPP solutions, when compared to surfactant-free carboxymethylcellulose (CMC) formulations (10).

Another important formulation parameter that can affect the microfabrication process is the ionic strength of the coating solution. Although the presence of buffer salts is highly desirable for maintaining stability of proteins and other biologically active molecules, they can also potentially weaken mechanical strength of microneedles, decrease drug loading, increase dissolution time, and even have adverse effects on the encapsulated material as salts get concentrated in the solid coating. Thus, reduction in the ionic strength to minimally acceptable levels appears to be an attractive strategy. Interestingly, decrease in the concentration of phosphate buffer, employed in our studies, led to some increase in coating performance (as measured by both PCPP and BSA loading) and viscosity of the formulation (Fig. 4). Variations in solution viscosity of polyelectrolytes depending on the content of simple electrolyte in aqueous solutions are well known and are typically associated with ion-screening effects modulating intramolecular electrostatic interactions in macromolecules (20,21). It has to be emphasized that even for solutions with highest buffer strength, the efficiency of coating formation was sufficiently high to enable effective microfabrication from the practical standpoint.

Surfactants, such as Tween, are important additives in the microfabrication process, since they can improve wetting properties of the formulation and uniformity of the coating (15). In addition, in the case of CMC formulations, Tween appears to be extremely effective in facilitating the coating process (Fig. 5). In a striking contrast, the addition of the same surfactant to PCPP-BSA formulation led to some reduction in the efficiency of microneedle coating formation (Fig. 5). The viscosities of the formulations were measured, and it was found that addition of Tween resulted in some decrease in the viscosity of PCPP formulation (14.2 to 12.4 cSt) and increase in the viscosity of CMC solution (13.5 to 14.5 cSt), which potentially provides explanation to the results on the coating formation (Fig. 5). Interestingly, 1% CMC formulation containing BSA and Tween displayed a higher viscosity than similar 0.5% PCPP formulation, and still its coating performance was somewhat inferior. This indicates potential influence of other parameters that require further investigations.

BSA loading in coated microneedles as a function of coating cycles for formulations containing PCPP and CMC in the presence and absence of surfactant (compositions contained 1% BSA and either 0.5% PCPP or 1% CMC; surfactant containing compositions also included 0.1% Tween; 0.005 M phosphate buffer, pH 7.4 was used as a solvent).

It is also noteworthy that protein loading profiles (Fig. 5) appear to display pronounced non-linearity, characterized by a noticeable increase in the efficiency at later stages of the process. This phenomenon can be better understood in the context of experimentally observed increase in the uptake of the formulation by microneedles with greater coating thickness. The volume of the formulation deposited on the microneedle, as estimated by microscopic examination of microneedles immediately before and after their contact with the formulation, gradually increases up to 10 times within the first 10 coating cycles. It is reasonable to assume that swelling of the increasing polymer coating can be responsible for this phenomenon.

Protein Stability in a Coating Process

Formation of solid-state formulation in a microfabrication process involves recurring dipping-drying cycles, which can be potentially detrimental to sensitive biologically active agents. Since polymers have been shown to modulate protein stability (22), it was important to evaluate the effect of PCPP as a microfabrication material on the maintenance of biological activity. Protein stability in the microfabrication process was studied by monitoring enzymatic activity of Horseradish Peroxidase (HRP). The efficiency of protein incorporation in microneedles was measured as a percent ratio between the activity of HRP released by dissolving the microneedle coating in an aqueous media (PBS, 7.4) and initial solution activity of the same amount of HRP that was used in the microfabrication process. As seen from Fig. 6, enzymatic activity of HRP was practically completely preserved in the coating process (93–97% of its initial activity) for the wide range of protein loadings. These results clearly indicate that the conditions of the coating process are sufficiently mild for this enzyme and HRP released from PCPP microneedles is functionally active.

Thermal Inactivation Studies of Protein Containing Formulations

One of the most significant advantages of solid formulations compared to their solution counterparts is that they can potentially offer improved shelf-life of drugs and vaccines and reduced dependence of their storage and transportation on temperature-controlled supply chains (22,23). Thus, coated microneedles with solid PCPP formulations containing HRP were tested in thermal inactivation studies, and the results were compared with those for aqueous solutions of HRP (Fig. 7). Thermal inactivation of HRP can be conveniently monitored using a chromogenic substrate system providing a reliable correlate with protein stability, as defined by thermally induced conformation changes (24,25). In such system we also have not observed any aggregation in HRP solutions both in the presence and absence of polymer (size-exclusion HPLC, data not shown), which is in accord with earlier findings (26).

Although the ambient temperature stability studies can be of significant practical interest, experimentally observed high stability of solid-state microneedle formulations presents challenges in quantitative comparison with solution formulation. In fact, our studies did not reveal noticeable changes in the activity of HRP in solid microneedles at 30°C within a period of 60 days, whereas the half-life of HRP in solution under similar conditions was only 7 days. We also conducted elevated temperature stability studies, in which microneedle formulations in a solid state were compared with solutions of HRP at 70°C. Remarkably, HRP encapsulated in solid PCPP coatings has been capable of withstanding such harsh thermal treatment for weeks, showing a half-life of 24 days (Fig. 7, circles). For comparison, HRP in an aqueous solution (PBS, pH 7.4) showed half-life of less than 1 h (Fig. 7, triangles). This over 500-fold increase in protein stability demonstrates another feature of PCPP microneedles, which can be important for their commercial development.

Protein Release from Coated Microneedles

In our studies, polyphosphazene coatings containing BSA prepared as described above were capable of dissolving practically instantaneously upon their contact with aqueous environment (PBS, pH 7.4). Rapid dissolution of polyphosphazene coating and fast release of the protein is generally highly desirable in terms of convenience and patient compliance, as it allows for a minimal patch application time. However, it can also be beneficial to prolong the release of the antigen in order to induce the “depot” effect, which can potentially result in a more potent and persistent immune response (8). Such sustained release can be achieved, for example, if the dissolution rate of the coating is reduced so that it can be deposited in the skin in the insoluble hydrogel state and release the antigen over an extended period of time.

Thus, it was of interest to investigate pathways for modulation of dissolution and release profiles. In this regard, the ability of PCPP to form complexes with salts of multivalent ions, such as calcium chloride and spermine, presented one of the most attractive opportunities (13,18,27). As a result of such complexation, three-dimensional hydrogel networks can be formed, leading potentially to a slower coating dissolution. This cross-linking process, which is “protein friendly” and can be carried out in an aqueous environment under mild conditions, has been successfully employed previously in microencapsulation technologies (18,27). The simplicity of the approach was especially appealing, since coatings on the microneedles can be easily treated with the solution of complex-forming salt using the same techniques and equipment that were employed for their deposition.

The feasibility of such methodology was evaluated by fabricating cross-linked coatings on the microneedles and measuring protein release and coating erosion (mass loss) profiles in vitro using 0.9% sodium chloride (pH 7.4) as a medium under sink conditions. The PCPP formulations were deposited on the microneedles as was described above and were then treated with solutions of calcium chloride and spermine. Sodium chloride was added to the cross-linking formulation to prevent in-process dissolution of PCPP; however, some loss of FITC-BSA was observed. This amount was approximately 8% of total protein in the coatings when using the single step cross-linking procedure and roughly 20% for the two-step procedure with spermine. The results are presented in Fig. 8.

BSA release from PCPP coated microneedles (circles), PCPP coated microneedles cross-linked with calcium chloride (squares), and PCPP coated microneedles cross-linked with calcium chloride and then spermine (triangles) versus time of incubation in the aqueous medium (release medium: 0.9% sodium chloride; microneedle loading: 40 µg/array of PCPP and 10 µg/array of FITC-BSA; cross-linking formulations and procedures as described in the text).

As expected, in the absence of a cross-linker, formulations demonstrated almost instantaneous dissolution of the coating and release of FITC-BSA in aqueous medium (Fig. 8). Cross-linked coatings displayed dramatic reductions in the rate of protein release as compared to their non-cross-linked counterparts with dual spermine-calcium system showing the best results (Fig. 8). In fact, contrary to highly soluble coatings, mass loss of the ionically cross-linked coating was less than 10% in the first 30 min of the experiment, whereas the half-release time for FITC-BSA was increased approximately 100-fold for calcium-spermine system compared to formulations which were not cross-linked (Fig. 8). This is consistent with previous findings on ionically complexed PCPP systems, in which the rate of erosion and protein release are determined by the kinetics of multivalent ion removal as a result of ion-exchange reactions with sodium ion in solution (18,28). The release profile was characterized with a substantial linear portion and did not have any indication of burst effect or induction period. Thus, ionic complexation of PCPP coatings can be a simple and effective approach to the modulation of protein release profiles.

CONCLUSIONS

Microneedle coating process using polyphosphazene systems has been studied with a focus on its relationship with solution behavior of PCPP formulations, such as protein-polymer complex formation. The latter has been shown to accelerate the efficiency of coating build-up, whereas environmental factors, such as buffer strength and the presence of surfactant, also played a significant role in the coating formation. Microfabrication process has not had any detrimental effect on the protein under the conditions studied. Upon encapsulation in microneedle coatings, protein has been stabilized compared to solution formulation to attain a more than 500-fold increase in half-life during elevated thermal inactivation studies at 70°C. Finally, an approach has been established in which ion-complexing properties of PCPP were exploited to achieve sustained protein release from microneedles.

REFERENCES

Holland D, Booy R, De Looze F, Eizenberg P, McDonald J, Karrasch J et al. Intradermal influenza vaccine administered using a new microinjection system produces superior immunogenicity in elderly adults: a randomized controlled trial. J Infect Dis. 2008;198:650–8.

Alarcon JB, Hartley AW, Harvey NG, Mikszta JA. Preclinical evaluation of microneedle technology for intradermal delivery of influenza vaccines. Clin Vaccine Immunol. 2007;14:375–81.

Hooper JW, Golden JW, Ferro AM, King AD. Smallpox DNA vaccine delivered by novel skin electroporation device protects mice against intranasal poxvirus challenge. Vaccine. 2007;25:1814–23.

Van Damme P, Oosterhuis-Kafeja F, Van der Wielen M, Almagor Y, Sharon O, Levin Y. Safety and efficacy of a novel microneedle device for dose sparing intradermal influenza vaccination in healthy adults. Vaccine. 2009;27:454–9.

Larregina AT, Falo Jr LD. Changing paradigms in cutaneous immunology: adapting with dendritic cells. J Investig Dermatol. 2004;124:1–12.

La Montagne JR, Fauci AS. Intradermal influenza vaccination—can less be more? N Engl J Med. 2004;351:2330–2.

Prausnitz MR, Mikszta JA, Cormier M, Andrianov AK. Microneedle-based vaccines. In: Compans RW, Orenstein WA, editors. Curr Top Microbiol Immunol Vol 333: Vaccines for Pandemic Influenza Springer, 2009.

Singh M, editor. Vaccine adjuvants and delivery systems. Hoboken: Wiley-Interscience; 2006.

Vogelbruch M, Nuss B, Korner M, Kapp A, Kiehl P, Bohm W. Aluminium-induced granulomas after inaccurate intradermal hyposensitization injections of aluminium-adsorbed depot preparations. Allergy. 2000;55:883–7.

Andrianov AK, DeCollibus DP, Gillis HA, Kha HH, Marin A, Prausnitz MR et al. Poly[di(carboxylatophenoxy)phosphazene] is a potent adjuvant for intradermal immunization. Proc Natl Acad Sci. 2009;106:18936–41.

Andrianov AK, Langer R. Polyphosphazenes for biology and medicine: current status and future prospects. In: Andrianov AK, editor. Polyphosphazenes for biomedical applications. Hoboken: Wiley; 2009. p. 3–13.

Andrianov AK. Polyphosphazene vaccine delivery vehicles: state of development and perspectives. In: Andrianov AK, editor. Polyphosphazenes for biomedical applications. Hoboken: Wiley; 2009. p. 47–63.

Andrianov AK, Svirkin YY, LeGolvan MP. Synthesis and biologically relevant properties of polyphosphazene polyacids. Biomacromolecules. 2004;5:1999–2006.

Gill HS, Prausnitz MR. Coated microneedles for transdermal delivery. J Control Release. 2007;117:227–37.

Gill HS, Prausnitz MR. Coating formulations for microneedles. Pharm Res. 2007;24:1369–80.

Gallati H. Horseradish peroxidase: a study of the kinetics and the determination of optimal reaction conditions, using hydrogen peroxide and 2, 2′-azinobis 3-ethylbenzthiazoline-6-sulfonic acid (ABTS) as substrates (author’s transl). J Clin Chem Clin Biochem. 1979;17:1–7.

Andrianov AK, Marin A, Roberts BE. Polyphosphazene polyelectrolytes: a link between the formation of noncovalent complexes with antigenic proteins and immunostimulating activity. Biomacromolecules. 2005;6:1375–9.

Andrianov AK, Chen J. Polyphosphazene microspheres: preparation by ionic complexation of phosphazene polyacids with spermine. J Appl Polymer Sci. 2006;101:414–9.

Andrianov AK, Marin A, Chen J. Synthesis, properties, and biological activity of Poly[di(sodium carboxylatoethylphenoxy)phosphazene]. Biomacromolecules. 2006;7:394–9.

Morawetz H. Polyelectrolyte solutions: phenomena and interpretation. Am Chem Soc. 2006;937:1–18.

Brilliantov NV, Kuznetsov DV, Klein R. Chain collapse and counterion condensation in dilute polyelectrolyte solutions. Phys Rev Lett. 1998;81:1433–6.

Wang W. Lyophilization and development of solid protein pharmaceuticals. Int J Pharm. 2000;203:1–60.

Rexroad J, Wiethoff CM, Jones LS, Middaugh CR. Lyophilization and the thermostability of vaccines. Cell Preserv Technol. 2002;1:91–104.

Pina DG, Shnyrova AV, Gavilanes F, Rodrнguez A, Leal F, Roig MG et al. Thermally induced conformational changes in horseradish peroxidase. Eur J Biochem. 2001;268:120–6.

Haifeng L, Yuwen L, Xiaomin C, Zhiyong W, Cunxin W. Effects of sodium phosphate buffer on horseradish peroxidase thermal stability. J Therm Anal Calorim. 2008;93:569–74.

Hassani L, Ranjbar B, Khajeh K, Naderi-Manesh H, Naderi-Manesh M, Sadeghi M. Horseradish peroxidase thermostabilization: the combinatorial effects of the surface modification and the polyols. Enzyme Microb Technol. 2006;38:118–25.

Andrianov AK, Chen J, Payne LG. Preparation of hydrogel microspheres by coacervation of aqueous polyphosphazene solutions. Biomaterials. 1998;19:109–15.

Andrianov AK, Payne LG. Protein release from polyphosphazene matrices. Adv Drug Deliv Rev. 1998;31:185–96.

ACKNOWLEDGEMENTS

The authors would like to thank Professor Mark. R. Prausnitz for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Andrianov, A.K., Marin, A. & DeCollibus, D.P. Microneedles with Intrinsic Immunoadjuvant Properties: Microfabrication, Protein Stability, and Modulated Release. Pharm Res 28, 58–65 (2011). https://doi.org/10.1007/s11095-010-0133-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-010-0133-7