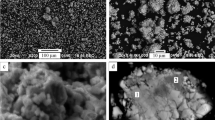

We reveal the competitive influence of two factors in the process of “dry” milling of Nd16 Fe 73.9 Zr 2.1 B 8 ferromagnetic alloy in hydrogen. As the rotation frequency of the mill chamber and the duration of the process increase, the range of particle sizes of the powder increases but particles become isotropic as a result of agglomeration. We indicate the possibility of application of a liquid medium (oleic acid) with an aim to prevent mechanical alloying of highly dispersed powder particles as a result of long high-energy milling. Highly dispersed anisotropic powders are obtained by milling of the alloy saturated with hydrogen in oleic acid at a rotation frequency of the mill chamber of 100–200 rpm for 12 h.

Similar content being viewed by others

References

R. Coehoorn, D. B. de Mooij, C. de Waard, “Meltspun permanent magnet materials containing Fe3B as the main phase,” J. Magnet. Magnet. Mater., 80, No. 1, 101–104 (1989).

G. C. Hadjipanayis and W. Gong, “Magnetic hysteresis in melt-spun Nd–Fe–Al–B–Si alloys with high remanence,” J. Appl. Phys., 64, No. 10, 5559–5561 (1988).

S. Liu, B. Cui, S. Bauser, et al., “Approach to synthesizing bulk, fully dense anisotropic nanocomposite rare-earth permanent magnets,” in: Proc. of the 17th Internat. Workshop on Rare-Earth Magnets and Their Applications (Newark, Delaware (USA), August 18–22, 2002), Rinton Press (2002), pp. 939–946.

J. Bernardi, T. Schrefl, J. Fidler, et al., “Preparation, magnetic properties, and microstructure of lean rare-earth permanent magnetic materials,” J. Magnet. Magnet. Mater., 219, No. 2, 186–198 (2000).

T. Yamamoto, T. Hidaka, T. Yoneyama, et al., “High remanence (Sm,Zr)Fe7N x +α-Fe nanocomposite magnets through exchange coupling,” J. Appl. Phys., 83, No. 11, 6917–6920 (1998).

J. Ding, P. G. McCormick, and R. Street, “Remanence enhancement in mechanically alloyed isotropic Sm7Fe93-nitride,” J. Magnet. Magnet. Mater., 124, Nos. 1, 2, 1–4 (1993).

N. Poudyal and J. P. Liu, “Advances in nanostructured permanent magnets research,” J. Phys. D: Appl. Phys., 46, No. 1, 1–23 (2013).

O. Gutfleisch, K. Khlopkov, A. Teresiak, et al., “Memory of texture during HDDR processing of NdFeB,” IEEE Trans. Magnet., 39, No. 5, 2926–2931 (2003).

I. І. Bulyk, V. V. Panasyuk, and A. M. Trostyanchyn, A Method for the Formation of Anisotropic Fine-Grained Structures of the Powders of Alloys of the Sm–Co System by Hydrogen-Vacuum Thermal Treatment [in Ukrainian], Patent of Ukraine, No. 96,810, H01F1/053; H01F1/055, B82B3/00, Publ. on 12.12.2011, Bul. No. 23.

I. І. Bulyk, V. V. Panasyuk, and A. M. Trostyanchyn, A Method for the Formation of Anisotropic Fine-Grained Structures of the Powders of Alloys of the Sm–Co System by Milling in Hydrogen [in Ukrainian], Patent of Ukraine, No. 96811H01F1/053, H01F1/055, B82B3/00, Publ. on 12.12.2011, Bul. No. 23.

I. І. Bulyk, A. M. Trostyanchyn, P. Ya. Lyutyi, and V. V. Burkhovets’kyi, “Specific features of the interaction of milled alloy based on SmCo5 with hydrogen,” Poroshk. Metall., 10, Nos. 9, 36–46 (2013).

I. І. Bulyk, A. M. Trostyanchyn, V. M. Dmytryshyn, and P. Ya. Lyutyi, A Method of Hydrogenation, Desorption, and Recombination (HDDR) under Low Hydrogen Pressures for the Formation of Anisotropic Fine-Grained Structures of the Powders of Alloys of the Sm–Co System and Preparation of Powders with These Structures [in Ukrainian], Patent of Ukraine No. 102899H01F7/00, H01F7/02, B22F 9/00, B22F9/04, Publ. 27.08.2013, Bul. No. 16.

J. Rodriguez-Carvajal, “Recent developments of the program FULLPROF,” Newsletter, 26, 12–19 (2001).

V. K. Pecharskii, L. G. Aksel’rud, and P. Yu. Zavalii, “On the method of taking into account the influence of preferred orientation (texture) in a powder specimen in the investigation of the atomic structure of substances,” Kristallografiya, No. 4, 874–877 (1987).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 50, No. 4, pp. 100–105, July–August, 2014.

Rights and permissions

About this article

Cite this article

Bulyk, І.І., Trostyanchyn, А.М., Burkhovets’kyi, V.V. et al. Dependence of the Phase Composition of Nd16Fe73.9Zr2.1B8 Alloy on the Conditions of Milling in Hydrogen. Mater Sci 50, 593–599 (2015). https://doi.org/10.1007/s11003-015-9758-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-015-9758-3