Abstract

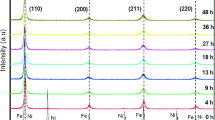

Nanocrystalline Fe50Co25Ni15X10 (X = Bamorphous, Bcrystalline, and Si) powdered alloys were prepared by mechanical alloying process. Morphological, microstructural, and structural characterizations of the powders milled several times were investigated by scanning electron microscopy and X-ray diffraction. The final crystallographic state strongly depends on the chemical composition and the grinding time; it can be single-phase or two-phase. The crystallite size reduction down the nanometer scale is accompanied by the introduction of high level of lattice strains. The dissolution of Co, Ni, B (amorphous and crystalline), and Si into the α-Fe lattice leads to the formation of highly disordered Fe-based solid solutions. Coercivity (Hc) and the saturation magnetization (Ms) of alloyed powders were measured at room temperature by a vibration sample magnetization. The magnetic measurements show a contrasting Ms and (Hc) in all alloy compositions. Conclusively, soft magnetic properties of nanocrystalline alloys are related to various factors such as metalloid addition, formed phases, and chemical compositions.

Similar content being viewed by others

References

Suryanarayana, C.: Mechanical alloying and milling. Prog. Mater. Sci. 46, 1 (2001)

Koch, C.C.: Top-down synthesis of nanostructured materials: mechanical and thermal processing methods. Rev. Adv. Mater. Sci. 5, 91–99 (2003)

Mancier, V., Delplancke, J.L., Delwiche, J., Hubin-Franskin, M.J., Piquer, C., Rebbouh, L., Grandjean, F.: Morphologic, magnetic, and Mossbauer spectral properties of Fe75Co25 nanoparticles prepared by ultrasound-assisted electrochemistry. J. Magn. Magn. Mater. 281, 27–35 (2004)

Zhu, J.G.: New heights for hard disk drives. Mater. Today. 6, 22–23 (2003)

Sharifati, A., Sharafi, S.: Structure and magnetic properties of mechanically alloyed (Fe70Co30)91Cu9 powder. Mater. Des. 36, 35–40 (2012)

Chitsazan, B., Shokrollahi, H., Behvandi, A., Mirzaee, O.: Characterization and magnetic coercivity of nanostructured (Fe50Co50)100-xVx= 0,2,4 powders containing a small amount of Co3V intermetallic obtained by mechanical alloying. Powder Technol. 214, 105–110 (2011)

Yuping, D., Yahong, Z., Tongmin, W., Shuchao, G., Xin, L., Xingjun, L.: Evolution study of microstructure and electromagnetic behaviors of Fe–Co–Ni alloy with mechanical alloying. Mater. Sci. Eng. B. 185, 86–93 (2014)

Baghbaderani, H.A., Sharafi, S., Chermahini, M.D.: Investigation of nanostructure formation mechanism and magnetic properties in Fe45Co45Ni10 system synthesized by mechanical alloying. Powder Technol. 230, 241–246 (2012)

Moumeni, H., Nemamcha, A., Alleg, S., Grenèche, J.M.: Hyperfine interactions and structural features of Fe-44Co-6Mo (wt.%) nanostructured powders. Mater. Chem. Phys. 138, 209–214 (2013)

Loureiro, J.M., Costa, B.F.O., Malaman, B., Le Caër, G., Das, S., Amaral, V.S.: Formation stages of bcc (Fe44Co44)Sn12 extended solid solution by mechanical alloying. J. Alloys Compd. 25, 211–218 (2014)

Lu, Z., Li, H., Lei, Z., Chang, C., Wang, X., Lu, Z.: The effects of metalloid elements on the nanocrystallization behavior and soft magnetic properties of FeCBSiPCu amorphous alloys. Metals. 8, 283 (2018)

Pang, L., Kumar, K.S.: Mater. Sci. Eng. A. 258, 161–166 (1998)

Kane, S.N., Gupta, A., Gercsi, Z., Mazaleyrat, F., Varga, L.K.: Magn. Magn. Mater. 292, 447 (2005)

Liu, B., Zheng, Y.F., Ruan, L.: Mater. Lett. 65(3), 540–543 (2011)

Filho, A.F., Bolfarini, C., Xu, Y., Kiminami, C.S.: Scr. Mater. 42, 213 (2000)

Yapp, R., Watts, B.E., Leccabue, F.: J. Magn. Magn. Mater. 215, 300 (2000)

Lutterotti, L.: MAUD CPD Newsletter. IUCr. 24, (2000)

Cardellini, F., Mazzone, G.: Thermal and structural study of the h.c.p.-to-f.c.c. transformation in cobalt. Philos. Mag. 67A(6), 1289–1300 (1993)

Sort, J., Nogues, J., Surinach, S., Munoz, J.S., Baro, M.D.: Correlation between stacking fault formation, allotropic phase transformations and magnetic properties of ball-milled cobalt. Mater. Sci. Eng. A. 375–377, 869–873 (2004)

Shokrallahi, H.: The magnetic and structural properties of the most important alloys of iron produced by mechanical alloying. Mater. Des. 30, 3374 (2009)

Long, J., Ohodnicki, P.R., Laughlin, D.E., McHenry, M.E.: Structural studies of secondary crystallization products of the Fe23B6-type in a nanocrystalline FeCoB-based alloy. J. Appl. Phys. 101, 09N114 (2007)

Souilah, S., Alleg, S., Djebbari, C., Bensalema, R., Sunol, J.J.: Magnetic and microstructural properties of the mechanically alloyed Fe57Co21Nb7B15 powder mixture. Mater. Chem. Phys. 132, 766–772 (2012)

Bensalem, R., Alleg, S., Younes, A., Souilah, S., Azzaza, S., Sunol, J.J.: Al-Azhar Univ. Eng. J. JAUES. 3(13), 83–92 (2008)

Herzer, G.: Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 26, 13977 (1990)

Delshad Chermahini, M., Sharafi, S., Shokrollahi, H., Zandrahimi, M., Shafyei, A.: The evolution of heating rate on the microstructural and magnetic properties of milled nanostructured Fe1-xCox(x = 0.2, 0.3, 0.4, 0.5 and 0.7) powder. J. Alloys Compd. 484, 54–58 (2009)

Luborsky, F.E.: Development of elongated particle magnets. J. Appl. Phys. 32, S171 (1961)

Kneller, E.: Fine particle theory. In: Berkowitz, A.E., Kneller, E. (eds.) Magnetism and Metallurgy, vol. 1, pp. 365–471. Academic Press, New York (1969)

Abdellaoui, M., Djega-Mariadassou, C., Gaffet, E.: Structural study of Fe-Si nanostructured materials. J. Alloys Compd. 259, 241 (1997)

Bensebaa, N., Loudjani, N., Alleg, S., Dekhil, L., Suñol, J.J., Al Sae, M., Bououdina, M.: XRD analysis and magnetic properties of nanocrystalline Ni20Co80 alloys. J. Magn. Magn. Mater. 323, 3063–3070 (2011)

Funding

Financial support from Spanish MAT2016-75967-P is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khitouni, N., Daly, R., Escoda, L. et al. The Effect of B and Si Additions on the Structural and Magnetic Behavior of Fe-Co-Ni Alloy Prepared by High-energy Mechanical Milling. J Supercond Nov Magn 33, 2727–2735 (2020). https://doi.org/10.1007/s10948-020-05500-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-020-05500-7