Abstract

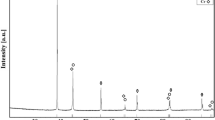

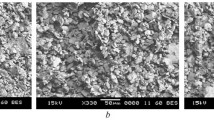

Nanocrystalline Fe — 40at.% Al alloy powders were prepared by using a mechanical alloying (MA) process with a planetary high-energy ball mill. The structural and the morphological properties of the powders were investigated by means of X-ray diffraction (XRD), and scanning electron microscopy (SEM), respectively. A disordered Fe(Al) solid solution with bcc crystal structure was formed after 10 h of MA. Longer MA durations introduced ordering in the alloyed powders. The final crystallite size was found to be as small as 5 nm whereas the internal strain was found to reach a final value of 2.1%. Also, the lattice parameter quickly increased to a maximum value of 0.2926 nm at 30 h of MA, and then decreased to a value of 0.2873 at 80 h of MA. SEM results showed variations in the shapes and the sizes of the particles in the powders at different stages. Furthermore, the microhardness values were found to increase gradually with increasing MA time due to work hardening, grain refinement and solid-solution formation. Magnetic properties such as the saturation magnetization (Ms) and the coercive field (Hc) were calculated from the hysteresis loops, and the results are presented as functions of the MA time.

Similar content being viewed by others

References

E. P. George and I. Baker, The Encyclopedia of Materials: Science and Technology (Elsevier Press, Oxford, 2001), p. 4201.

L. D’Angelo, L. D’Onofrio and G. Gonzalez, J. Alloys Comp. 483, 154 (2009)

H. Wu, I. Baker, Y. Liu, X. Wu and J. Cheng, Intermetallics 19, 1517 (2011).

M. Mhadhbi, M. Khitouni, L. Escoda, J. J. Sunol and M. Dammak, J. Alloys Comp. 509, 3293 (2011).

F. Hadef, A. Otmani, A. Djekoun and J. M. Greneche, J. Magn. Magn. Mater. 326, 261 (2013).

M. Krifa, M. Mhadhbi, L. Escoda, J. M. Guell, J. J. Sunol, N. Llorca-Isern, C. Artieda-Guzman and M. Khitouni, J. Alloys Comp. 554, 51 (2013).

N. Boukherroub, A. Guittoum, N. Souami, K. Akkouche and S. Boutarfaia, EPJ Web Conf. 29, 00010 (2012).

E. Menendez, J. Sort, M. O. Liedke, J. Fassbender, S. Surinach, M. D. Baro and J. Nogues, New J. Phys. 10, 103030 (2008).

R. Bernal-Correa, A. Rosales-Rivera, P. Pineda-Gomez and N. A. Salazar, J. Alloys Comp. 495, 491 (2010).

Y. Jiraskova, J. Bursik, J. Cizek and D. Jancik, J. Alloys Comp. 568, 106 (2013).

C. Suryanarayana, Mechanical Alloying and Milling (Marcel Dekker, New York, 2004).

M. Gogebakan and B. Avar, Mater. Sci. Tech. 26, 920 (2010).

M. Gogebakan and B. Avar, Pramana J. Phys. 77, 735 (2011).

F. Hadef, A. Otmani, A. Djekoun and J. M. Greneche, Super Microstruct. 49, 654 (2011).

Z. Hamlati, A. Guittoum, S. Bergheul, N. Souami, K. Taibi and M. Azzaz, J. Mater. Eng. Perform. 21, 1943 (2012).

M. Krifa, M. Mhadhbi, L. Escoda, J. M. Guell, J. J. Sunol, N. Llorca-Isern, C. Artieda-Guzman and M. Khitouni, Powder Tech. 246, 117 (2013).

K. Wolski, G. Le Caer, P. Delcroix, R. Fillit, F. Thevenot and J. Le Coze, Mater. Sci. Eng. A 207, 97 (1996).

X. Amils, J. Nogues, S. Surinach, M. D. Baro, M. A. Munoz-Morris and D. G. Morris, Intermetallics 8, 805 (2000).

Q. Zeng, I. Baker, Intermetallics 14, 396 (2006).

J. Nogues et al., Phys. Rev. B 74, 024407 (2006).

H. Shokrollahi, Mater. Des. 30, 3374 (2009).

L. E. Zamora, G. A. P. Alcazar, G. Y. Velez, J. D. Betancur, J. F. Marco, J. J. Romero, A. Martinez, F. J. Palomares and J. M. Gonzalez, Phys. Rev. B 79, 094418 (2009).

MDI Jade Software, XRD pattern processing, Material Data Inc. Livermare CA, USA.

M. Mhadhbi, M. Khitouni, L. Escoda, J. J. Sunol and M. Dammak, J. Nanomater. 2010, 712407 (2010).

M. Kezrane, A. Guittoumb, N. Boukherroubc, S. Lamranic and T. Sahraoui, J. Alloys Comp. 536S, 304 (2012).

M. M. Rajath Hegde and A. O. Surendranathan, Powder Metall. Metal Ceram. 48, 641 (2009).

M. H. Enayati, G. R. Aryanpour and A. Ebnonnasir, Int. J. Ref. Met. Hard. Mater. 27, 159 (2009).

Z. Hamlati, A. Guittoum, S. Bergheul, N. Souami, K. Taibi and M. Azzaz, Adv. Mater. Res. 214, 490 (2011).

M. Khajepour and S. Sharafi, Powder Tech. 232, 124 (2012).

M. Rafiei, M. H. Enayati and F. Karimzadeh, J. Mater. Sci. 45, 4058 (2010).

M. A. Morris-Munoz, A. Dodge and D. G. Morris, Nanostruct. Mater. 11, 873 (1999).

M. Krasnowski and T. Kulik, Intermetallics 15, 201 (2007).

B. Song, S. Dong, P. Coddet, H. Liao and C. Coddet, Surf. Coat. Technol. 206, 4704 (2012).

S. Izadi, G. H. Akbari and K. Janghorban, J. Alloys Comp. 496, 699 (2010).

J. A. Plascak, L. E. Zamora and G. A. P. Alcazar, Phys. Rev. B 61, 3188 (2000).

N. Bensebaa, N. Loudjani, S. Alleg, L. Dekhil, J. J. Sunol, M. Al Sae and M. Bououdina, J. Magn. Magn. Mater. 349, 51 (2014).

A. Guittoum, A. Layadi, A. Bourzami, H. Tafat, N. Souami, S. Boutarfaia and D. Lacour, J. Magn. Magn. Mater. 320, 1385 (2008).

A. H. Bahrami, H. Ghayour and S. Sharafi, Powder Tech. 249, 7 (2013).

A. Sharifati, S. Sharafi, Mater. Des. 41, 8 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Avar, B., Gogebakan, M., Ozcan, S. et al. Structural, mechanical and magnetic properties of Fe — 40-at.% Al powders during mechanical alloying. Journal of the Korean Physical Society 65, 664–670 (2014). https://doi.org/10.3938/jkps.65.664

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3938/jkps.65.664