Abstract

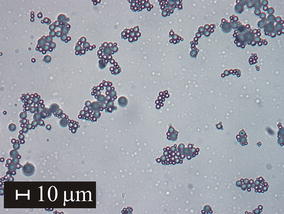

DSC, SEM–EDS, XRD and high-temperature XRD analysis was used to study thermal and crystallization behaviour of yttrium aluminate glasses prepared in the form of microspheres. The glasses YA-E (eutectic composition from the pseudo-binary system Al2O3–Y3Al5O12) and YA-G (a composition identical to the stoichiometric Y3Al5O12 (YAG) phase) were prepared by combination of the Pechini method with flame synthesis. The resulting microspheres were largely amorphous, but contained traces of yttrium–aluminium garnet as the main crystalline phase embedded in the yttrium aluminate glass matrix. Crystallization of the YAG phase was observed as the dominant exothermic process on DSC curves. From the DSC records, the basic thermal characteristics of the matrix glass, i.e. T g (glass transition temperature), T x (onset of crystallization peak temperature), T f (temperature of the inflection point of the crystallization peak) and T p (maximum of crystallization peak temperature), were determined. HT XRD experiments in the temperature interval 750–1200 °C and isothermal HT XRD experiments at 932, 998 and 1200 °C with 6-h holding time were also performed. Crystallization experiments at lower temperatures 932 °C (YA-E) and 915 °C (YA-G) were conducted to study phase development in a low-temperature region. Crystallization experiments at higher temperatures (1000, 1300 and 1500 °C) with maximum holding time of 6 h were performed to study crystallization of α-Al2O3 in the eutectic system. The SEM and SEM–EDS examination of polished cross sections of crystallized microspheres revealed slow volume crystallization of the YAG phase in the AY-E glass. Eventually, polycrystalline microspheres with fine-grained microstructure were prepared after 6-h treatment at 1500 °C.

Similar content being viewed by others

References

Flunder F, Mitchel BS. Infrared studies of processing effects in calcium aluminate glasses. J Non-Cryst Solids. 1998;224:184.

Wallenberger FT, Weston NE, Motzfeldt K, Swartzfager DG. Inviscid melt spinning of alumina fibers: chemical jet stabilization. J Am Ceram Soc. 1992;75:629.

Rosenflanz A, Frey M, Endres B, Anderson T, Richards E, Schardt C. Bulk glasses and ultrahard nanoceramics based on alumina and rare-earth oxides. Nature. 2004;430:761.

Rodrigues AM, Costa AMC, Cabral AA. Effect of simultaneous nucleation and crystal growth on DSC crystallisation peak of glasses. J Am Ceram Soc. 2012;95:2885.

Cabral AA, Fokin VM, Zanotto ED. On the determination of nucleation rates in glasses by nonisothermal methods. J Am Ceram Soc. 2010;93:2438.

Ray CS, Day DE, Huang W, Narayan KL, Cull TS. Non-isothermal calorimetric studies of the crystallization of lithium disilicate glass. J Non-Cryst Solids. 1996;204:1.

Fuss T, Ray CS, Kitamura N, Makihara M, Day DE. Pressure induced nucleation in Li2O–SiO2 glass. J Non-Cryst Solids. 2003;318:157.

Narayan KL, Kelton KF, Ray CS. Effect of Pt doping on nucleation and crystallization in Li2O–SiO2 glass: experimental measurements and computer modeling. J Non-Cryst Solids. 1996;195:148.

Reis ST, Kim CW, Brow RK, Ray CS. Nucleation and crystallization as induced by bending stress in lithium silicate glass fibers. J Non-Cryst Solids. 2004;348:1.

Karamanov A, Pisciella P, Pelino M. The crystallisation kinetics of iron rich glass in different atmospheres. J Eur Ceram Soc. 2000;20:2233.

Mošner P, Vosejpková K, Koudelka L. Thermal properties and stability of TeO2 containing phosphate glasses. Thermochim Acta. 2011;522:155.

Ahmad S, Ludwig T, Herrmann M, Mahmoud MM, Lippmann W, Seifert HJ. Phase evaluation during high temperature long heat treatments in the Y2O3–Al2O3–SiO2 system. J Eur Ceram Soc. 2014;34:3835.

Pechini MP. Method of preparing lead and alkaline-earth titanates and niobates and coating method using the same to form a capacitor. U.S. Pat. No. 3 330 697, 1967.

Li X, Wang W. Preparation of uniformly dispersed YAG ultrafine powders by co-precipitation method with SDS treatment. Powder Technol. 2009;196:26.

Huang H, Gong H, Tang D, Tan OK. Synthesis and characterization of ytrium aluminum garnet by high energy ball milling. Opt Mater. 2009;31:716.

Bhattacharyyja H, Ghatak S. Synthesis and characterization of YAG precursor powder in the hydroxyhydrogel form. Ceram Int. 2009;35:29.

Grujic S, Blagojevic N, Tosic M, Zivanovic V. Structural and crystallization characteristics of K2O–TiO2–GeO2 glass. Ceramics-Silikáty. 2005;49:278.

Mošner P, Vosejpková K, Koudelka L. Thermal properties and stability of lithium titano-phosphate glasses. J Therm Anal Cal. 2009;95:53.

Wallin E. Alumina thin film growths, experiments and modeling. [licentiate thesis No. 1292]. Linkoping: Linkoping University; 2007.

Prnová A, Bodišová K, Klement R, Migát M, Veteška P, Škrátek M, Bruneel E, Driessche IV, Galusek D. Preparation and characterization of Yb2O3–Al2O3 glasses by the Pechini sol–gel method combined with flame synthesis. Ceram Int. 2014;40:6179.

Acknowledgements

The financial support of this work by the project SAS-MOST JRP 2015/6, VEGA 1/0631/14 and VEGA 2/0058/14 is gratefully acknowledged. This publication was created in the frame of the project “Centre of excellence for ceramics, glass, and silicate materials” ITMS code 262 201 20056, based on the Operational Program Research and Development funded from the European Regional Development Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prnová, A., Klement, R., Bodišová, K. et al. Thermal behaviour of yttrium aluminate glasses studied by DSC, high-temperature X-ray diffraction, SEM and SEM–EDS. J Therm Anal Calorim 128, 1407–1415 (2017). https://doi.org/10.1007/s10973-016-6078-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-6078-2