Abstract

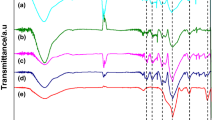

Novel copper containing epoxy polymers have been synthesized using copper(II) formamidine complex [Cu(ampf)Cl2], ampf = N,N′-bis(4-acetyl-5-methylpyrazole-3-yl)formamidine, as curing agent for diglycidyl ether of bisphenol A-based epoxy resins (Araldite and its oligomer consisting of 3–4 monomer units). The curing reaction was performed at room temperature without catalyst. In order to prove the polymerization reaction, differential scanning calorimetry (DSC) was applied. Highly exothermic peaks around 150 °C refer to the polymerization, and according to DSC results, the epoxy resins above 200 °C were almost completely converted to the corresponding metal-containing polymer. The proposed structure of the hybrid polymers was confirmed by FT-IR analysis. Gel permeation chromatography analysis shows that the average molar masses of the polymers are in the range from 3,000 to 50,000 g mol−1. The low conductivities of the hybrid materials in tetrahydrofuran confirm the non-ionic structure of the new polymers in solution. The thermal stability and the decomposition mechanism of the components of the reaction mixture and the new polymers were studied by coupled TG/DTA-MS measurements. The thermal data were analysed also with the aim to obtain additional information about the composition of the synthesized materials.

Similar content being viewed by others

References

Ellis B. Chemistry and technology of epoxy resins. Glasgow: Blackie Academic and Professional; 1993. p. 37.

Cella J, Schwabacher A, Shuls A. Cationic chelate salts of main group elements as curing agents for epoxy resins. Znd Eng Chem Prod Res Deu. 1983;22:20–5.

Kurnoskin AV, Lapitsky VA. Sinteza Struktura Svoistva Medsoderzhashchikh Polimerov, Abstracts of Papers. Vsesoyuznaya Konferentsiya, Zvenigorod, 1988, 55.

Kurnoskin AV. Metal-containing epoxy polymers. In: Cheremisinoff NP, Cheremisinoff PN, editors. Handbook of applied polymer processing technology. New York: Marcel Dekker; 1996. p. 703–65.

Kurnoskin AV. Metalliferous epoxy-chelate polymers: analytical review. JMS Rev Macromol Chem Phys. 1996;C36:457–599.

Kurnoskin AV. Epoxy polymer modification with metals. Polym Compos. 1993;14:481–90.

Lin KF, Shu WY, Wey TL. Organotransition-metal complexes as additives for epoxy resins: Part 1. Their effects on toughness and morphology of epoxy resins. Polymer. 1993;34:277–88.

Lin KF, Wang WH. Imidazole and chromium acetylacetonate as additives for the cure and fracture-toughness of epoxy resins and their composites. Polym Compos. 1995;16:269–75.

Lin KF, Shu WY, Wey TL. Organotransition-metal complexes as additives for epoxy resins: Part 2. Interaction with epoxy resins. Polymer. 1993;34:2162–8.

Anand M, Srivastava AK. Synthesis and characterization of epoxy resins containing arsenic acrylate. Polym Eng Sci. 1997;37:183–7.

Anand M, Srivastava AK. Synthesis and characterization of epoxy resins containing chromium acrylate. Angew Makromol Chem. 1994;219:1–10.

Anand M, Srivastava AK. Synthesis of zinc-containing epoxy resin. J Appl Polym Sci. 1994;51:203–11.

Kurnoskin AV, Korshikov LA, Kanovich MZ, Filatova LD, Soloveva EK. Optimization of the curing regime for epoxychelate composite materials with the results of evaluation of residual stresses. Fibre Chem. 1995;27:266–9.

Chantarasiria N, Tuntulania T, Tongraunga P, Seangprasertkit-Mageea R, Wannarong W. New metal-containing epoxy polymers from diglycidyl ether of bisphenol A and tetradentate Schiff base metal complexes. Eur Polym J. 2000;36:695–702.

Kurnoskin AV, Kanovitch MZ, Ilyin VM, Gusev LL, Bekeshko VV. Application of epoxychelate composites in automobile industry. Inf Bull Khim Prom SEV. 1990;6:25–9.

Hamerton I, Howlin BJ, Jepson P. Metals and coordination compounds as modifiers for epoxy resins. Coord Chem Rev. 2002;224:67–85.

Kurnoskin AV. Epoxy chelate copper-containing polymers: their chemistry and production. Polym Plas Tech Eng. 1992;31:505–25.

Kurnoskin AV. Metalliferous epoxy chelate polymers: 1. Synthesis and properties. Polymer. 1993;34:1060–7.

Hollό B, Leovac VM, Bombicz P, Kovács A, Jovanović LS, Bogdanović G, Kojić V, Divjaković V, Joksović MD, Mészáros Szécsényi K. Synthesis, structural, DFT, and cytotoxicity studies of CuII and NiII complexes with 3-aminopyrazole derivatives. Aust J Chem. 2010;63:1557–64.

Prasad RL, Kushwaha A, Szilágyi IM, Kótai L. Solid state thermal degradation behaviour of 1-d coordination polymers of Ni(II) and Cu(II) bridged by conjugated ligand. J Therm Anal Calorim. 2013;114:653–64.

Szilágyi IM, Deák A, Várhelyi C Jr, Madarász J, Pokol G, Gömöry Á, Várhelyi C. Structural and thermal study of asymmetric a-dioxime complexes of Co(III) with Cl and methyl-pyridines. Polyhedron. 2010;10:2185–9.

Tatsumiya S, Yokokawa K, Miki K. A dynamic DSC study of the curing process of epoxy resin. J Therm Anal. 1997;49:123–9.

Rosu D, Cascaval C, Mustata F, Ciobanu C. Cure kinetics of epoxy resins studied by non-isothermal DSC data. Thermochim Acta. 2002;383:119–27.

Silverstein R, Bassler C, Morrill T. Spectrometric identification of organic compounds, vol. 3rd. New York: Wiley International Edition; 1974. p. 108.

Quan C, Li A, Gao N. Research on pyrolysis of PCB waste with TG-FTIR and Py-GC/MS. J Therm Anal Calorim. 2012;110:1463–70.

Xu J, He Z, Wu W, Ma H, Xie J, Qu H, Jiao Y. Study of thermal properties of flame retardant epoxy resin treated with hexakis[p-(hydroxymethyl)phenoxy]cyclotriphosphazene. J Therm Anal Calorim. 2013;114:1341–50.

Hunyadi D, Sajo I, Szilágyi IM. Structure and thermal decomposition of ammonium metatungstate. J Therm Anal Calorim. 2014;116:329–37.

Balabanovicha AI, Hornunga A, Merza D, Seifert H. The effect of a curing agent on the thermal degradation of fire retardant brominated epoxy resins. Polym Degrad Stab. 2004;85:713–23.

Wang X, Hu Y, Song L, Xing W, Lu H. Thermal degradation mechanism of flame retarded epoxy resins with a DOPO-substituted organophosphorus oligomer by TG-FTIR and DP-MS. J Anal Appl Pyrol. 2011;92:164–70.

Qian L, Ye L, Qiu Y, Qu S. Thermal degradation behavior of the compound containing phosphaphenanthrene and phosphazene groups and its flame retardant mechanism on epoxy resin. Polymer. 2011;52:5486–93.

http://www.webbook.nist.gov/. Accessed 12 Dec 2013.

Ahamad T, Alshehri SM. Thermal degradation and evolved gas analysis of epoxy (DGEBA)/novolac resin blends (ENB) during pyrolysis and combustion. J Therm Anal Calorim. 2013;111:445–51.

Huang Z, Shi W. Thermal behavior and degradation mechanism of poly(bisphenyl acryloxyethyl phosphate) as a UV curable flame-retardant oligomer. Polym Degrad Stab. 2006;91:1674–84.

Acknowledgements

This paper was supported by the Ministry of Education, Science and Technological Development, Republic of Serbia; contract Grant numbers: III 45022 and ON 172014. B. Barta Holló acknowledges a Domus Hungarica Fellowship. I. M. Szilágyi acknowledges a János Bolyai Research Fellowship of the Hungarian Academy of Sciences, and an OTKA-PD-109129 Grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ristić, I.S., Barta Holló, B., Budinski-Simendić, J. et al. Synthesis of novel metal-containing epoxy polymers and their structural characterization by means of FT-IR and coupled TG/MS measurements. J Therm Anal Calorim 119, 1011–1021 (2015). https://doi.org/10.1007/s10973-014-4242-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-4242-0