Abstract

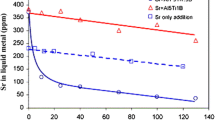

Bismuth, antimony and strontium concentrations were optimised to alter the eutectic Al–Si phase in a commercial Al–Si–Cu–Mg alloy by way of computer-aided cooling curve thermal analysis. The results show that the eutectic growth temperature shifted to lower temperatures for all three inoculants. However, addition of Sr resulted in more depression of growth temperature compared with Bi and Sb. No further significant changes were observed with increasing the concentrations to more than 1, 0.5 and 0.04 wt% of Bi, Sb and Sr, respectively. The recalescence of these concentrations, meanwhile, showed a significant increase of magnitude. A good correlation was found between the results of thermal and microstructural analysis. For Bi and Sb, the eutectic depression temperature can be used as an individual criterion to gauge optimal levels of content in the refinement of Si, whereas for Sr, both depression temperature and recalescence magnitude must be considered. Based on the observed depression in eutectic growth temperature and recalescence, it can be concluded that the optimal concentrations to refine the eutectic Al–Si phase with Bi and Sb and to modify it with Sr at the given solidification conditions were 1, 0.5 and 0.04 wt%, respectively.

Similar content being viewed by others

References

Xiufang B, Zhang Z, Xiangfa L. Effect of strontium modification on hydrogen content and porosity shape of Al–Si alloys. Mater Sci Forum. 2000;331–337:361–6.

Dahle AK, Nogita K, McDonald SD, Dinnis C, Lu L. Eutectic modification and microstructure development in Al–Si Alloys. Mater Sci Eng A. 2005;413–414:243–8.

Hegde S, Narayan Prabhu K. Modification of eutectic silicon in Al–Si alloys. Mater Sci. 2008;43(9):3009–27.

Dasgupta R, Brown CG, Marek S. Analysis of overmodified 356 aluminum alloy. AFS Trans. 1998;96:297–310.

Wang L, Shivkumar S. Strontium modification of aluminium alloy castings in the expendable pattern casting process. Mater Sci. 1995;30(6):1584–94.

Evans WJ, Nowicki RM, Cole GS. Measuring the quality of aluminium casting alloys with microprocessor-aided thermal analysis. AFS Trans. 1985;93:199–204.

Emadi D, Whiting LV, Nafisi S, Ghomashchi R. Applications of thermal analysis in quality control of solidification processes. J Therm Anal Calorim. 2005;81:235–42.

Leonhard H, Schneider W. Influence of alloying elements on the thermal analysis results of Al–Si cast alloys. Light Met. 2002;2:17–26.

Riddle YW, Makhlouf MM. Characterizing solidification by non-equilibrium thermal analysis. In: Kaplan HI, editor. Magnesium technology 2003. San Diego, CA: TMS; 2003. p. 101–6.

Backerud L, Chai G, Tamminen J. Foundry alloys. In: Solidification characteristics of aluminum alloys, Vol. 2. Stockholm, Sweden: AFS/Skanaluminium; 1990.

Apelian D, Sigworth GK, Whaler KR. Assessment of grain refinement and modification of Al–Si foundry alloys by thermal analysis. AFS Trans. 1984;92:297–307.

Mahfoud M, Emadi D. Application of heat pipe technology in thermal analysis of metals. J Therm Anal Calorim. 2005;81:161–7.

Mahfoud M, Prasada Rao AK, Emadi D. The role of thermal analysis in detecting impurity levels during aluminum recycling. J Therm Anal Calorim. 2010;100(3):847–51.

Lu L, Dahle AK. Effects of combined additions of Sr and AlTiB grain refiners in hypoeutectic Al–Si foundry alloys. Mater Sci Eng A. 2006;435–436:288–96.

Knuutinen A, Nogita K, McDonald SD, Dahle AK. Modification of Al–Si alloys with Ba, Ca, Y and Yb. Light Met. 2001;1:229–40.

Malekan M, Shabestari SG. Computer-aided cooling curve thermal analysis used to predict the quality of aluminum alloys. J Therm Anal Calorim. 2011;103:453–8.

Djurdjevic M, Jiang H, Sokolowski J. On-line prediction of aluminum–silicon eutectic modification level using thermal analysis. Mater Charact. 2001;46:31–8.

Lu L, Nogita K, Dahle AK. Combining Sr and Na additions in hypoeutectic Al–Si foundry alloys. Mater Sci Eng A. 2005;399:244–53.

Tsai YC, Chou CY, Lee SL, Lin CK, Lin JC, Lim SW. Effect of trace La addition on the microstructures and mechanical properties of A356 (Al–7Si–0.35 Mg) aluminum alloys. J Alloys Compd. 2009;487(1–2):157–62.

Prukkanon W, Srisukhumbowornchai N, Limmaneevichitr C. Modification of hypoeutectic Al–Si alloys with scandium. J. Alloys Compd. 2009;477:454–60.

Gruzleski JE, Closset BM. The treatment of liquid aluminium–silicon alloys. Des Plains, IL: AFS; 1990. p. 95–157.

Hosch T, England LG, Napolitano RE. Analysis of the high growth-rate transition in Al–Si eutectic solidification. Mater Sci. 2009;44:4892–9.

Nogita K, asuda H, Yoshiya M, McDonald SD, Uesugi K, Takeuchi A, Suzuki Y. The role of trace element segregation in the eutectic modification of hypoeutectic Al–Si alloys. J Alloys Compd. 2010;489:415–20.

Acknowledgements

The authors acknowledge Universiti Teknologi Malaysia for providing research facilities and the Ministry of Science and Technology of Malaysia for financial support under the vot 79352.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farahany, S., Ourdjini, A. & Idris, M.H. The usage of computer-aided cooling curve thermal analysis to optimise eutectic refiner and modifier in Al–Si alloys. J Therm Anal Calorim 109, 105–111 (2012). https://doi.org/10.1007/s10973-011-1708-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1708-1