Abstract

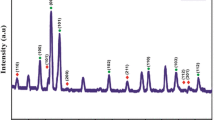

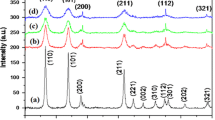

Mixed metal oxides of tin with strontium (xSnO2.SrO) in different molar ratio {where x = 1 (1), 2 (2), 4(3); SnO2 doped with Sr+2(4), SnO2 doped with Sr+2 and co-doped with F−(5)} have been prepared by sol–gel technology in basic medium using SnCl2.2H2O as precursor in isopropanol as solvent. Structural analysis by XRD patterns have shown formation of particles at nanoscale and phase separation of SnO2 in tetragonal rutile framework in these mixed metal oxides. This fact was further supported by TEM. SEM images of all these samples have shown formation of various geometrical patterns ranging from spherical particles to nanorods. In the IR spectra of all these oxides, Sr–O absorption bands were present only in sample (1). UV–Vis spectroscopy has shown reduction in optical band gap in mixed metal oxides and the lowest value of band gap was observed for sample (3). Photoluminescence spectra of all these derivatives are found to be almost similar again indicated retention of tetragonal rutile SnO2 framework. I–V curves of all these oxides are non-linear and lowest resistance was observed for sample (3). This fact was further supported by impedance measurements.

Highlights

-

Mixed metal oxides of SnO2 and SrO in different stoichiometric ratios have been prepared by sol–gel technology in basic medium.

-

XRD patterns have shown separation of phases and retention of tetragonal rutile framework in SnO2.

-

SEM images have shown formation of various geometrical patterns ranging from spherical particles to nanorods.

-

UV–Vis spectroscopy has shown reduction in optical band gap in these mixed metal oxides.

-

IV curves and impedance measurements have shown comparatively high conductance in sample (3).

Similar content being viewed by others

References

Thangaraju B (2002) Thin Solid Films 402:71–78

Baker PGL, Sanderson RD, Crouch AM (2007) Thin Solid Films 515:6691–6697

Liu Y, Li Y, Zeng H (2013) J Nanomater 2013:1–9

Bargougui R, Oueslati A, Schmerber G, Ulhaq-Bouillet C, Colis S, Hlel F, Ammar S, Dinia A (2014) J Mater Sci: Mater Electron 25:2066–2071

Banyamin ZY, Kelly PJ, West G, Boardman J (2014) Coatings 4:732–746

Sagadevan S, Podder J (2015) Soft Nanosci Lett 5:55–64

Khan N, Athar T, Foud H, Umar A, Ansari ZA, Ansari SG (2017) Scientific reports 7, Article No. 42510. p 11

Sharma V (2017) J Sol-gel Sci Technol 84:231–238

Patil GE, Kajale DD, Gaikwad VB, Jain GH (2012) Int Nano Lett 2:46–51

Helwig A, Muller G, Svervegkieri G, Faglia G (2008) Sens Actuators B130:193–199

Kadhim IH, Hassan HA, Abdullah QN (2016) Nano Micro Lett 8:20–28

Zhao Q, Ma L, Zhang Q, Wang C, Xu X (2015) J Nanomater 2015:1–15

Kalpana D, Omkumar KS, Kumar SS, Ranganathan N (2006) Electrochim Acta 52(3):1309–1315

Yadav AA, Masumdar EU, Moholkar AV, Neumann-Spallart M, Rajpure KY, Bhosle CH (2009) J Alloy Compd 488:350–355

He Z, Zhou J (2013) Mod Res Catal 2:13–18

Liu Y, Koep E, Liu M (2005) Chem Meter 17(15):3997–4000

Chacko S, Bushiri MJ, Vaidyan VK (2006) J Phys D-Appl Phys 39:4540–4543

Elangovan E, Ramamurthi K (2005) Thin Solid Films 476:231–236

Nütz T, Haase M (2000) J Phys Chem B 104:8430–8437

Blessi S, Sonia MML, Vijayalakshmi S, Pauline S (2014) Int J Res (IJCRGG) 6(3):2153-2155

Bhagwat AD, Sawant SS, Ankamwar BG, Mahajan CM (2015) J Nano Electron Phys 7(4):4037. (4pp)

Agrawal S, Sharma V, Bohra R (2006) J Chem Res 7:426–430

Sharma N, Sharma V, Bohra R, Raju VS (2007) Appl Org -Met Chem 21:763–771

Sharma N, Sharma V, Bohra R, Raju VS, Lorenz I-P, Krinninger C, Mayer P (2007) Inorg Chim Acta 360:3002–3012

Dhayal V, Sharma N, Sharma V, Bohra R, Drake JE, McDonald CLB (2007) Polyhedron 26:3168–3174

Mishra S, Daniele S (2015) Chem Rev 115:8379–8448

Nemade KR, Waghuley SA (2013) J Results Phys 3:52–54

Hamedani HA, Allam NK, Garmestani H, EI-Sayed MA (2011) J Phys Chem C 115:13480–13486

Kim S, Yang Y, Oh WK, Kim C, Jang J (2014) Adv Healthc Mater 3:1097–1106

Ueno S, Nakashima K, Sakamoto Y, Wad S (2015) Nanomaterials 5:386–397

Luo J, Shen P, Yao W, Jiang C, Xu J (2016) Nanoscale Res Lett 11: 141(14 pp).

Thompson S, Shirtcliffe NJ, O’Keefe ES, Appleton S, Perry CC (2005) J Magn Magn Mater 292:100–107

Jose R, Suzuki T, Ohishi Y (2006) J Non-Cryst Solids 352:5564–5568

Veverka P, Knižek K, Pollert E, Bohaček J, Vasseur S, Duguet D, Portier J (2007) J Magn Magn Mater 309(1):106–112

Luo J, Xu Y, Gao D (2015) Solid State Sci 37:40–46

Lashanizadegan M, Mousavi F, Mirzazahed H (2016) J Ceram Process Res 17:586–590

Wong-Ng W, Cline JP, Cook LP, Greenwood W (2000) Adv X-ray Anal 42:355–365

Smith MB, Page K, Siegrist T, Redmond PL, Walter EC, Sheshadry R, Brus LE, Steigerwald ML (2008) J Am Chem Soc 130:6955–6963

Zou GL, Liu R, Chen WX, Zu ZD (2007) Mater Res Bull 42:1153–1158

Zhang J, Gao L (2004) J Solid State Chem 4-5:1425–1430

Pasierb P, Komornicki S, Rokita M, Rekas M (2001) J Mol Struct 596:151–156

Bonu V, Das A, Amirthapandian S, Dhara S, Tyagi AK (2015) Phys Chem Chem Phys 17:9794–9801

Sudhaparimala S, Gnanamania A, Mandal AB (2014) Am J Nanosci Tech 2:75–83

Rajeshwaran P, Shivarajan A (2015) J Mater Sci: Mater Electron 26:539–546

Mazumder N, Bharti A, Saha S, Sen D, Chattopadhyay KK (2012) Curr Appl Phys 12:975–982

Chu CW, F. Chen, Shulman J, Tsui S, Xue YY, Wen W, Sheng P (2005) Proc. SPIE 5932, Strongly Correlated Electron Materials: Physics and Nanoengineering, 59320X. arXiv: cond-mat/0511166[cond.mat.Supr.con] p 9

Acknowledgements

V Sharma is thankful to UGC- New Delhi for financial support (No. MS-37/304004/XII/13-14/CRO dated 19 January 2015). We are thankful to Material Research Center, MNIT, Jaipur Rajasthan for providing all technical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

sharma, V., Prajapati, R.C. Synthesis of mixed metal oxide nanoparticles of SnO2 with SrO via sol–gel technology: their structural, optical, and electrical properties. J Sol-Gel Sci Technol 87, 41–49 (2018). https://doi.org/10.1007/s10971-018-4718-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4718-7