Abstract

The graphene-reinforced chemically bonded phosphate ceramics (GCBPCs) are prepared on A3 steel. X-ray diffraction and Raman spectra are used to analyze the GCBPCs. The curing kinetics of GCBPCs are also analyzed with differential scanning calorimetry, and the microstructures are tested by scanning electron microscope. It is found that AlPO4 and Zn3(PO4)2 are the main binding phases in GCBPCs. And there is no reaction between graphene and composites. However, the enthalpies of curing increase with the increase in graphene. And ceramic platelets are found with adding graphene because the gel that produces in the curing process crystallizes around the graphene into ceramic platelets. In addition, electrochemical tests are conducted to investigate the corrosion behavior of GCBPCs. The corrosion current densities decrease from 2.76E−6 to 1.21E−7 A/cm2, and the protection efficiency increases from 33.81 to 97.10 % with the increase in graphene. Besides, the charge transfer resistance and resistance of coatings also increase with the increase in graphene. The corrosion mechanism of the GCBPCs is investigated based on the corrosion behavior and microstructural characterizations. The excellent corrosion resistance is mainly contributed by the graphene platelets and the ceramic platelets that form in the curing process. These platelets block the diffusion pathway and make the pathway more tortuous, which can effectively prevent H2O, O2 and Cl− from accessing the substrate.

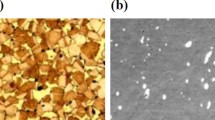

Graphical Abstract

In GCBPC0, the H2O, O2 and Cl− accessed the substrate through the diffusion pathway without resistance. In GCPBC5, the diffusion pathway was blocked t and made more tortuous by the graphene platelets and ceramic platelets formed.

Similar content being viewed by others

References

Wang Y, Ni Z, Chen G, Chen A, Su Y, Zhao Y (2012) Effect of the number of layers on the bond strength for multi-layer brittle coating-substrate system. Sci China-Technol Sci 55(10):2936–2940. doi:10.1007/s11431-012-4958-7

Brown IG, Anders A, Dickinson MR, MacGill RA, Monteiro OR (1999) Recent advances in surface processing with metal plasma and ion beams. Surf Coat Technol 112(1–3):271–277. doi:10.1016/s0257-8972(98)00769-5

Bian D, Yang D, Zhao Z, Huang G, Wang Y, Ni Z, Zhao Y (2015) Effect of elastic modulus and thickness of the interlayer on the bond strength for ceramic coating-substrate system. Ceram Int 41(7):9088–9092. doi:10.1016/j.ceramint.2015.03.284

Shen S, Cai S, Xu G, Zhao H, Niu S, Zhang R (2015) Influence of heat treatment on bond strength and corrosion resistance of sol-gel derived bioglass-ceramic coatings on magnesium alloy. J Mech Behav Biomed Mater 45:166–174. doi:10.1016/j.jmbbm.2015.02.005

Zhou W, Liu M, Chen N, Sun X (2015) Corrosion properties of sol–gel silica coatings on phosphated carbon steel in sodium chloride solution. J Sol-Gel Sci Technol 76(2):358–371. doi:10.1007/s10971-015-3784-3

Dalbin S, Maurin G, Nogueira RP, Persello J, Pommier N (2005) Silica-based coating for corrosion protection of electrogalvanized steel. Surf Coat Technol 194(2–3):363–371. doi:10.1016/j.surfcoat.2004.07.126

Klabunde KJ (2002) Nanoscale materials in chemistry. Wiley, New York

Bian D, Zhao Y (2015) Influence of nano-alumina on curing kinetics and corrosion resistance of alumina based ceramic coatings. Russ J Appl Chem 88(10):1718–1722. doi:10.1134/s1070427215100250

Huang T, Xin Y, Li T, Nutt S, Su C, Chen H, Liu P, Lai Z (2013) Modified graphene/polyimide nanocomposites: reinforcing and tribological effects. Acs Appl Mater Interfaces 5(11):4878–4891. doi:10.1021/am400635x

Ren G, Zhang Z, Zhu X, Ge B, Guo F, Men X, Liu W (2013) Influence of functional graphene as filler on the tribological behaviors of Nomex fabric/phenolic composite. Compos A Appl Sci Manuf 49:157–164. doi:10.1016/j.compositesa.2013.03.001

Novoselov KS, Fal'ko VI, Colombo L, Gellert PR, Schwab MG, Kim K (2012) A roadmap for graphene. Nature 490(7419):192–200

Pigney A, Laurent C, Flahaut E, Rousset A (2000) Carbon nanotubes in novel ceramic matrix nanocomposites. Ceram Int 26(6):677–683

Chang C-H, Huang T-C, Peng C-W, Yeh T-C, Lu H-I, Hung W-I, Weng C-J, Yang T-I, Yeh J-M (2012) Novel anticorrosion coatings prepared from polyaniline/graphene composites. Carbon 50(14):5044–5051

Compton OC, Kim S, Pierre C, Torkelson JM, Nguyen ST (2010) Crumpled graphene nanosheets as highly effective barrier property enhancers. Adv Mater 22(42):4759

Singh BP, Nayak S, Nanda KK, Jena BK, Bhattacharjee S, Besra L (2013) The production of a corrosion resistant graphene reinforced composite coating on copper by electrophoretic deposition. Carbon 61:47–56

Suna W, Wanga L, Wub T, Pana Y, Guichang L (2014) Synthesis of low-electrical-conductivity graphene/pernigraniline composites and their application in corrosion protection. Carbon 79:605–614

Kumar CMP, Venkatesha TV, Shabadi R (2013) Preparation and corrosion behavior of Ni and Ni–graphene composite coatings. Mater Res Bull 48(4):1477–1483. doi:10.1016/j.materresbull.2012.12.064

Khalil MW, Eldin TAS, Hassan HB, El-Sayed K, Hamid ZA (2015) Electrodeposition of Ni-GNS-TiO2 nanocomposite coatings as anticorrosion film for mild steel in neutral environment. Surf Coat Technol 275:98–111. doi:10.1016/j.surfcoat.2015.05.033

Punith Kumar MK, Singh MP, Srivastava C (2015) Electrochemical behavior of Zn-graphene composite coatings. RSC Adv 5(32):25603–25608. doi:10.1039/C5RA02898A

Praveen BM, Venkatesha TV (2009) Electrodeposition and properties of Zn–Ni–CNT composite coatings. J Alloys Compd 482(1–2):53–57. doi:10.1016/j.jallcom.2009.04.056

Deng S, Wang C, Zhou Y, Huang F, Du L (2011) Preparation and characterization of fiber-reinforced aluminum phosphate/silica composites with interpenetrating phase structures. Int J Appl Ceram Technol 8(2):360–365

Wagh AS, Grover S, Jeong SY (2003) Chemically bonded phosphate ceramics: II, warm-temperature process for alumina ceramics. J Am Ceram Soc 86(11):1845–1849

Yazdani B, Xu F, Ahmad I, Hou X, Xia Y, Zhu Y (2015) Tribological performance of Graphene/Carbon nanotube hybrid reinforced Al2O3 composites. Sci Rep 11579

Wagh AS, Jeong SY (2003) Chemically bonded phosphate ceramics: I, a dissolution model of formation. J Am Ceram Soc 86(11):1838–1844

Malard LM, Pimenta MA, Dresselhaus G, Dresselhaus MS (2009) Raman spectroscopy in graphene. Phys Rep 473(5–6):51–87. doi:10.1016/j.physrep.2009.02.003

Delhaes P, Couzi M, Trinquecoste M, Dentzer J, Hamidou H, Vix-Guterl C (2006) A comparison between Raman spectroscopy and surface characterizations of multiwall carbon nanotubes. Carbon 44(14):3005–3013. doi:10.1016/j.carbon.2006.05.021

Kudin KN, Ozbas B, Schniepp HC, Prud’homme RK, Aksay IA, Car R (2008) Raman spectra of graphite oxide and functionalized graphene sheets. Nano Lett 8(1):36–41. doi:10.1021/nl071822y

Rani S, Kumar M, Sharma S, Kumar D (2014) Role of graphene in structural transformation of zirconium oxide. J Sol-Gel Sci Technol 71(3):470–476. doi:10.1007/s10971-014-3401-x

Johra FT, Lee M-J, Jung W-G (2013) Solution-based fabrication of a graphene–ZnO nanocomposite. J Sol-Gel Sci Technol 66(3):481–487. doi:10.1007/s10971-013-3035-4

Inam F, Vo T, Bhat BR (2014) Structural stability studies of graphene in sintered ceramic nanocomposites. Ceram Int 40(10, Part B):16227–16233. doi:10.1016/j.ceramint.2014.07.058

Shao F, Yang K, Zhao H, Liu C, Wang L, Tao S (2015) Effects of inorganic sealant and brief heat treatments on corrosion behavior of plasma sprayed Cr2O3–Al2O3 composite ceramic coatings. Surf Coat Technol 276:8–15. doi:10.1016/j.surfcoat.2015.06.045

Nofz M, Zietelmann C, Feigl M, Dörfel I, Saliwan Neumann R (2015) Microstructural origin of time-dependent changes in alumina sol–gel-coated Inconel 718 exposed to NaCl solution. J Sol-Gel Sci Technol 75(1):6–16. doi:10.1007/s10971-015-3668-6

Liu D, Zhao W, Liu S, Cen Q, Xue Q (2016) Comparative tribological and corrosion resistance properties of epoxy composite coatings reinforced with functionalized fullerene C60 and graphene. Surf Coat Technol 286:354–364. doi:10.1016/j.surfcoat.2015.12.056

Acknowledgments

The authors gratefully acknowledge the supports of Doctoral Science Program of China (Grant No. JUDCF13028), the Natural Science Foundation of the Higher Education Institutions of Jiangsu Province (Grant No. BK20130143), Postdoctoral Science Foundation of Jiangsu Province (Grant No. 1002028C) and Postdoctoral Science Foundation of China (Grant No. 20110491366).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bian, D., Zhao, Y. Preparation and corrosion mechanism of graphene-reinforced chemically bonded phosphate ceramics. J Sol-Gel Sci Technol 80, 30–37 (2016). https://doi.org/10.1007/s10971-016-4061-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4061-9