Abstract

Inconel 718 was spin coated twice and fourfold with a sol to obtain 200- and 400-nm-thick transition alumina films on the surface. Bare and sol–gel alumina-coated Inconel 718 samples were exposed to NaCl solution to study their corrosion behavior by means of electrochemical impedance spectroscopy. In combination with scanning electron microscopy, it was shown that bare Inconel 718 is after initial passivation prone to pitting corrosion. For the coated Inconel 718 samples, an improvement in the protective effect of the coatings with time was observed. This observation is in contradiction to the results of other authors who observed degradation of alumina coatings exposed to NaCl solution with time. Transmission electron microscopy revealed a formation of (1) a compacted region at the coating surface as well as (2) a chromium-rich region at the interface between coating and alloy during the contact with a NaCl solution. The last one mainly contributes to the observed chronological sequence of electrochemical characteristics of the samples.

Graphical Abstract

Similar content being viewed by others

References

Saunders SRJ, Monteiro M, Rizzo F (2008) The oxidation behavior of metals and alloys at high temperatures in atmospheres containing water vapour: a review. Prog Mater Sci 53:775–837

Dίaz B, Härkönen E, Światowska J, Maurice V, Seyeux A, Marcus P, Ritala M (2011) Low-temperature atomic layer deposition of Al2O3 thin coatings for corrosion protection of steel: surface and electrochemical analysis. Corros Sci 53:2168–2175

Dίaz B, Härkönen E, Maurice V, Światowska J, Seyeux A, Ritala M, Marcus P (2011) Failure mechanism of thin Al2O3 coatings grown by atomic layer deposition for corrosion protection of carbon steel. Electrochim Acta 56:9609–9618

Lazar A, Prieto Yespica W, Marcelin S, Pébère N, Samélor D, Tendero C, Vahlas C (2014) Corrosion protection of 304L stainless steel by chemical vapor deposited alumina coatings. Corros Sci 81:125–131

Ruhi G, Modi OP, Singh IB (2009) Pitting of AISI 304L stainless steel coated with nano structured sol–gel alumina coatings in chloride containing acidic environments. Corros Sci 51:3057–3063

Chen T, John H, Xu J, Lu Q, Hawk J, Liu X (2013) Influence of surface modifications on pitting corrosion behavior of nickel base alloy 718. Part 1: effect of machine hammer peening. Corros Sci 77:230–245

Chen T, John H, Xu J, Lu Q, Hawk J, Liu X (2014) Influence of surface modifications on pitting corrosion behavior of nickel base alloy 718. Part 2: effect of aging treatment. Corros Sci 78:151–161

Chang MY, Yu G-P (1993) Pitting corrosion of Inconel 600 in chloride and sulfate solutions at low temperature. J Nucl Mater 202:145–153

Yoldas BE (1975) Alumina sol preparation from alkoxides. Am Ceram Soc Bull 54:289–290

Marsal A, Ansart F, Turq V, Bonino JP, Sobrino JM, Chen YM, Garcia J (2013) Mechanical properties and tribological behavior of a silica or/and alumina coating prepared by sol–gel route on stainless steel. Surf Coat Technol 237:234–240

Schimanski J (1998) Production of dispersible aluminas and their use in different applications. Key Eng Mater 150:161–170

Masalski J, Gluszek J, Zabrzeski J, Nitsch K, Gluszek P (1999) Improvement in corrosion resistance of the 3161 stainless steel by means of Al2O3 coatings deposited by the sol–gel method. Thin Solid Films 349:186–190

Ruhi G, Modi OP, Singh IB (2009) Corrosion behavior of nano structured sol–gel alumina coated 9Cr–1Mo ferritic steel in chloride bearing environment. Surf Coat Technol 204:359–365

Tiwari SK, Sahu RK, Pramanick AK, Singh R (2011) Development of conversion coating on mild steel prior to sol gel nanostructured Al2O3 coating for enhancement of corrosion resistance. Surf Coat Technol 205:4960–4967

Wang T, Pu J, Bo C, Jian L (2010) Sol–gel prepared Al2O3 coatings for the application as tritium permeation barrier. Fusion Eng Des 85:1068–1072

Bottino A, Broglia M, Capanelli G, Comite A, Pinacci P, Scrignari M, Azzurri F (2014) Sol–gel synthesis of thin alumina layers on porous stainless steel supports for high temperature palladium membranes. Int J Hydrog Energy 39:4717–4724

Chui-Sabourin M, Garofalini SH (1991) Effect of substrate ob crystallization of sol–gel coating. Thin Solid Films 198:177–190

Vasconcelos DCL, Oréfice RL, Vasconcelos WL (2007) Processing, adhesion and electrical properties of silicon steel having non-oriented grains coated with silica and alumina sol–gel. Mater Sci Eng A 447:77–82

Adraider Y, Hodgson SNB, Sharp MC, Zhang ZY, Nabhani F, Al-Waidh A, Pang YX (2012) Structure characterization and mechanical properties of crystalline alumina coatings on stainless steel fabricated via sol–gel technology and fibre laser processing. J Eur Ceram Soc 32:4229–4240

Clark DE, Dalzell WJ, Folz DC (1988) Electrophoretic alumina sol–gel coatings on metallic substrates. Ceram Eng Sci Proc 9:1111–1118

Clark DE, Dalzell WJ, Adams BL (1989) Inorganic salts as peptizing agents in the preparation of metal oxide sol–gel compositions. United States Patent No. 4,801,399

Nofz M, Pauli J, Dressler M, Jäger C, Altenburg W (2006) 27Al NMR study of Al-speciation in aqueous alumina-sols. J Sol-Gel Sci Technol 38:25–35

Dressler M, Nofz M, Gemeinert M (2006) Rheology, UV–Vis transparency and particle size of modified Yoldas sols. J Sol-Gel Sci Technol 38:261–269

Schulz W, Nofz M, Feigl M, Dörfel I, Saliwan Neumann R, Kranzmann A (2013) Corrosion of uncoated and alumina coated steel X20CrMoV12-1 in H2O–CO2–O2 and air at 600 °C. Corros Sci 68:44–50

Schulz W, Feigl M, Dörfel I, Nofz M, Kranzmann A (2013) Influence of sol–gel alumina coating on oxidation of X20CrMoV12-1 in air up to 650 °C. Thin Solid Films 539:29–34

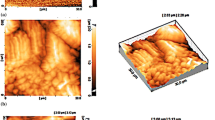

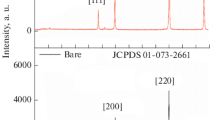

Dressler M, Nofz M, Saliwan Neumann R, Dörfel I, Griepentrog M (2008) Sol–gel derived alumina layers on nickel-base superalloy Inconel-718 (IN-718). Thin Solid Films 517:786–792

Dressler M, Nofz M, Dörfel I, Saliwan-Neumann R (2012) Diffusion of Cr, Fe, and Ti ions from Ni-base alloy Inconel-718 into a transition alumina coating. Thin Solid Films 520:4344–4349

Dressler M, Nofz M, Dörfel I, Saliwan-Neumann R (2008) Influence of sol–gel derived alumina coatings on oxide scale growth of nickel-base superalloy Inconel-718. Surf Coat Technol 202:6095–6102

Inconel® alloy 718. Publication Number SMC-045 (2007) Special metals corporation. http://www.specialmetals.com/documents/Inconel%20alloy%20718.pdf. Accessed 12 Sept 2014

Dressler M, Nofz M, Malz F, Pauli J, Jäger C, Reinsch S, Scholz G (2007) Aluminum speciation and thermal evolution of aluminas resulting from modified Yoldas sols. J Solid State Chem 180:2409–2419

Pepe A, Galliano P, Aparicio M, Duran A, Ceré S (2006) Sol–gel coatings on carbon steel: electrochemical evaluation. Surf Coat Technol 200:3486–3491

Liu L, Zhai C, Lu C, Ding W, Hirose A, Kobayashi KF (2005) Study of the effect of δ phase on hydrogen embrittlement of Inconel 718 by notch tensile tests. Corros Sci 47:355–367

Connolley T, Reed PAS, Starink MJ (2003) Short crack initiation and growth at 600 °C in notched specimens of Inconel718. Mater Sci Eng A 340:139–154

Sarmento VHV, Schiavetto MG, Hammer P, Benedetti AV, Fugivara CS, Suegama PH, Pulcinelly SH, Santilli CV (2010) Corrosion protection of stainless steel by polysiloxane hybrid coatings prepared using the sol–gel process. Surf Coat Technol 204:2689–2701

Kritzer P, Boukis N, Dinjus E (1999) Factors controlling corrosion in high-temperature aqueous solutions: a contribution to the dissociation and solubility data influencing corrosion processes. J Supercrit Fluids 15:205–227

Park J-J, Pyun S-I, Lee S-B (2004) Growth kinetics of passivating oxide film of Inconel alloy 600 in 0.1 M Na2SO4 solution at 25–300 °C using the abrading electrode technique and ac impedance spectroscopy. Electrochim Acta 49:281–292

Caliari FR, da Rosa EF, da Silva MA, Reis DAP (2014) Analysis of pitting corrosion on an Inconel 718 alloy submitted to aging heat treatment. Tecnol Metal Mater Miner 11:189–194

Kunst SR, Cardoso HRP, Oliveira CT, Santana JA, Sarmento VHV, Muller IL, Malfatti CF (2014) Corrosion resistance of siloxane-poly(methyl methacrylate) hybrid films modified with acetic acid on tin plate substrates: influence of tetraethoxysilane addition. Appl Surf Sci 298:1–11

Metikoš-Huković M, Tkalčec E, Kwokal A, Piljac J (2003) An in vitro study of Ti and Ti-alloys coated with sol–gel derived hydroxyapatite coatings. Surf Coat Technol 165:40–50

Dressler M, Nofz M, Klobes P, Dörfel I, Reinsch S (2010) Differences between films and monoliths of sol–gel derived aluminas. Thin Solid Films 519:42–51

Evanko CR, Delisio RF, Dzombak DA, Novak JW Jr (1997) Influence of aqueous solution chemistry on the surface charge, viscosity and stability of concentrated alumina dispersions in water. Colloids Surf A 125:95–107

Roelofs F, Vogelsberger W (2006) Dissolution kinetics of nanodispersed γ-alumina in aqueous solution at different pH: unusual kinetic size effect and formation of a new phase. Colloids Interface Sci 303:450–459

Liu Q, Wang A, Wang X, Gao P, Wang X, Thang T (2008) Synthesis, characterization and catalytic applications of mesoporous γ-alumina from boehmite sol. Microporous Mesoporous Mater 111:323–333

Bleta R, Alphonse P, Pin L, Gressier M, Menu M-J (2012) An efficient route to aqueous phase synthesis of c-Al2O3 with high porosity: from stable boehmite colloids to large pore mesoporous alumina. J Colloid Interface Sci 367:120–128

Girginov A, Popova A, Kanazirski I, Zahariev A (2006) Characterization of complex anodic alumina films by electrochemical impedance spectroscopy. Thin Solid Films 515:1548–1551

Farelas F, Galicia M, Brown B, Nesic S, Castaneda H (2010) Evolution of dissolution process at the interface of carbon steel corroding in a CO2 environment studied by EIS. Corros Sci 52:509–517

Acknowledgments

We wish to thank Deutsche Forschungsgemeinschaft (DFG) for funding and Mrs. Rooch for preparing the TEM samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nofz, M., Zietelmann, C., Feigl, M. et al. Microstructural origin of time-dependent changes in alumina sol–gel-coated Inconel 718 exposed to NaCl solution. J Sol-Gel Sci Technol 75, 6–16 (2015). https://doi.org/10.1007/s10971-015-3668-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3668-6