Abstract

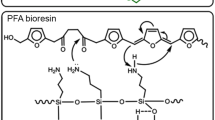

Low toxicity, environmentally friendly and sustainable bio-based phenol–formaldehyde (PF) resins are the primary factors and health goals that researchers need to consider when modifying PF resins. Two novel biomass-modified PF resins were synthesized using two flavonoid phenols of daidzein and naringenin with rigid backbone structures. The results show that compared with ordinary PF, the introduction of daidzein and naringenin during the synthesis of N-PF and D-PF can delay the curing reaction and results in higher curing peak temperatures. The appropriate substitution rate of daidzein and naringenin can improve the crosslinking degree, resulting in N-PF and D-PF with higher thermal stability, ablation resistance and mechanical properties. The highest carbon yield YC800 for N-PF is 59.81% (56.85%for PF-1), and the highest YC800 for D-PF is 64.39% (PF-2 with 58.15%). The maximum tensile strength and flexural strengths of N-PF are respective 33.86 MPa and 110.42 MPa (28.77 and 79.89 MPa for PF-1), and the maximum tensile strength and flexural strengths of D-PF are respective 35.61 MPa and 103.17 MPa (24.48 and 55.79 MPa for PF-2). The D-PF and N-PF resins modified and enhanced by daidzein and naringenin have lower friction coefficient and more excellent wear resistance than pure PF.

Similar content being viewed by others

References

B. Kiskan, Y. Yagci, The journey of phenolics from the first spark to advanced materials. Isr J Chem. 60(1–2), 20–32 (2020)

Y. He, R. Duan, Q. Zhang, T. Xia, B. Yan, S. Zhou, J. Huang, Reinforce the mechanical toughness, heat resistance, and friction and wear resistance of phenolic resin via constructing self-assembled hybrid particles of graphite oxide and zirconia as nano-fillers. Adv. Compos. Hybrid. Ma. 4(2), 317–323 (2021)

L.P. de Hoyos-Martínez, H. Issaoui, R. Herrera, J. Labidi, F. Charrier-El Bouhtoury, Wood fireproofing coatings based on biobased phenolic resins. ACS. Sustain. Chem. Eng. 9(4), 1729–1740 (2021)

K. Zhang, Z. Shang, S. Wu, Commercialized benzoxazine resin-derived porous carbon as high performance electrode materials for supercapacitor. J Inorg Organomet Polym 27(5), 1423–1429 (2017)

A. Beda, P.L. Taberna, P. Simon, C. Matei Ghimbeu, Hard carbons derived from green phenolic resins for Na-ion batteries. Carbon 139, 248–257 (2018)

Z. Wei, H.X. Zhao, Y.B. Niu, S.Y. Zhang, Y.B. Wu, H.J. Yan, S. Xin, Y.X. Yin, Y.G. Guo, Insights into the pre-oxidation process of phenolic resin-based hard carbon for sodium storage. Chem. Front. 5(10), 3911–3917 (2021)

Y. Xu, L. Guo, H. Zhang, H. Zhai, H. Ren, Research status, industrial application demand and prospects of phenolic resin. RSC Adv. 9(50), 28924–28935 (2019)

C. Wu, Z. Chen, F. Wang, Enhanced anti-ablation and alkali corrosion resistance of graphene oxide modified urea-melamine-phenol formaldehyde composites reinforced by R-glass fiber. J Inorg Organomet Polym 29, 1818–1826 (2019)

T.G. Babu, R. Devasia, Boron modified phenol formaldehyde derived Cf/SiBOC composites with improved mechanical strength for high temperature applications. J Inorg Organomet Polym 26(4), 764–772 (2016)

N.B. Mansour, W. Djeridi, L. ElMir, Preparation, properties and applications of the hybrid organic/inorganic nanocomposite based on nanoporous carbon matrix. J Inorg Organomet Polym 31, 4360–4371 (2021)

F.F. Binda, V.D.A. Oliveira, C.A. Fortulan, L.B. Palhares, C.G. dos Santos, Friction elements based on phenolic resin and slate powder. Res. Technol. 9(3), 3378–3383 (2020)

L. Wang, M.X. Liu, F.H. Yang, Comparative study on the structure, mechanical, thermal, and tribological properties of PF composites reinforced by different kinds of mesoporous silicas. J Inorg Organomet Polym 31, 2939–2948 (2021)

W.M. Moreira, P.V. Viotti, A.A. de Moura, M.L. Gimenes, M.G.A. Vieira, Synthesis of a biobased resin and its screening as an alternative adsorbent for organic and inorganic micropollutant removal. Environ. Sci. Pollut. Res. Int. 29, 79935–79953 (2022)

D. Torres, S. Pérez-Rodríguez, L. Cesari, C. Castel, E. Favre, V. Fierro, A. Celzard, Review on the preparation of carbon membranes derived from phenolic resins for gas separation: from petrochemical precursors to bioresources. Carbon 183, 12–33 (2021)

L. Guo, Y. Yang, F. Xu, Q. Lan, M. Wei, Y. Wang, Design of gradient nanopores in phenolics for ultrafast water permeation. Chem. Sci. 10(7), 2093–2100 (2019)

X. Xing, Y. Zhao, X. Zhang, J. Wang, T. Hong, Y. Li, S. Wang, C. Zhang, X. Jing, Healable ablative composites from synergistically crosslinked phenolic resin. Chem. Eng. J. 447, 137571 (2022)

L. Granado, R. Tavernier, S. Henry, R.O. Auke, G. Foyer, G. David, S. Caillol, Toward sustainable phenolic thermosets with high thermal performances. ACS Sustain. Chem. Eng. 7(7), 7209–7217 (2019)

C. Nair, Advances in addition-cure phenolic resins. Polym. Sci. 29(5), 401–498 (2004)

J. Chen, K. Zhang, K. Zhang, B. Jiang, Y. Huang, Facile preparation of reprocessable and degradable phenolic resin based on dynamic acetal motifs. Polym. Degrad. Stabil. 196, 109818 (2022)

K. Błażek, J. Datta, Renewable natural resources as green alternative substrates to obtain bio-based non-isocyanate polyurethanes-review. Crit. Rev. Environ. Sci. Technol. 49(3), 173–211 (2019)

A. Noreen, K.M. Zia, M. Zuber, S. Tabasum, A.F. Zahoor, Bio-based polyurethane: an efficient and environment friendly coating systems: a review. Prog. Org. Coat. 91, 25–32 (2016)

C. Zhang, J. Xue, X. Yang, Y. Ke, R. Ou, Y. Wang, S.A. Madbouly, Q. Wang, From plant phenols to novel bio-based polymers. Prog. Polym. Sci. 125, 101473 (2022)

M. Derradji, O. Mehelli, W. Liu, N. Fantuzzi, Sustainable and ecofriendly chemical design of high performance bio-based thermosets for advanced applications. Front. Chem. 9, 691117 (2021)

J. Liu, S. Wang, Y. Peng, J. Zhu, W. Zhao, X. Liu, Advances in sustainable thermosetting resins: from renewable feedstock to high performance and recyclability. Prog. Polym. Sci. 113, 101353 (2021)

P.R. Sarika, P. Nancarrow, A. Khansaheb, T. Ibrahim, Bio-based alternatives to phenol and formaldehyde for the production of resins. Polymers -Basel. 12(10), 2237 (2020)

F.A.M.M. Gonçalves, M. Santos, T. Cernadas, P. Ferreira, P. Alves, Advances in the development of biobased epoxy resins: insight into more sustainable materials and future applications. Int. Mater. Rev. 67(2), 119–149 (2021)

G. Mashouf Roudsari, A.K. Mohanty, M. Misra, Green approaches to engineer tough biobased epoxies: a review. Chem Eng 5(11), 9528–9541 (2017)

K. Tang, A. Zhang, T. Ge, X. Liu, X. Tang, Y. Li, Research progress on modification of phenolic resin. Mater. Today Commun. 26, 101879 (2021)

G. Foyer, B.H. Chanfi, D. Virieux, G. David, S. Caillo, Aromatic dialdehyde precursors from lignin derivatives for the synthesis of formaldehyde-free and high char yield phenolic resins. Eur. Polym. J. 77, 65–74 (2016)

W. Yang, L. Jiao, X. Wang, W. Wu, H. Lian, H. Dai, Formaldehyde-free self-polymerization of lignin-derived monomers for synthesis of renewable phenolic resin. Int. J. Biol. Macromol. 166, 1312–1319 (2021)

C. Bo, L. Hu, Y. Chen, X. Yang, M. Zhang, Y. Zhou, Synthesis of a novel cardanol-based compound and environmentally sustainable production of phenolic foam. J. Mater. Sci. 53(15), 10784–10797 (2018)

V. Barbosa, E.C. Ramires, I.A.T. Razera, E. Frollini, Biobased composites from tannin–phenolic polymers reinforced with coir fibers. industrial crops and products. Ind. Crop. Prod. 32(3), 305–312 (2010)

E.C. Ramires, E. Frollini, Tannin–phenolic resins: Synthesis, characterization, and application as matrix in biobased composites reinforced with sisal fibers. Part B-Eng. 43(7), 2851–2860 (2012)

J. Xu, N. Brodu, M. Mignot, B. Youssef, B. Taouk, Synthesis and characterization of phenolic resins based on pyrolysis bio-oil separated by fractional condensation and water extraction. Biomass Bioenergy. 159, 106393 (2022)

L. Granado, R. Tavernier, G. Foyer, G. David, S. Caillol, Catalysis for highly thermostable phenol-terephthalaldehyde polymer networks. Chem. Eng. J. 379, 122237 (2020)

R. Oye Auke, G. Arrachart, R. Tavernier, G. David, S. Pellet-Rostaing, Terephthalaldehyde-phenolic resins as a solid-phase extraction system for the recovery of rare-earth elements. Polymers-Basel. 14(2), 311 (2022)

Y. Zhang, Z. Yuan, N. Mahmood, S. Huang, C. Xu, Sustainable bio-phenol-hydroxymethylfurfural resins using phenolated de-polymerized hydrolysis lignin and their application in bio-composites. Ind. Crop. Prod. 79, 84–90 (2016)

Z. Yuan, Y. Zhang, C. Xu, Synthesis and thermomechanical property study of Novolac phenol-hydroxymethyl furfural (PHMF) resin. RSC Adv. 4(60), 31829–31835 (2014)

M. Siahkamari, S. Emmanuel, D.B. Hodge, M. Nejad, Lignin-glyoxal: a fully biobased formaldehyde-free wood adhesive for interior engineered wood products. Chem. Eng. 10(11), 3430–3441 (2022)

I. Van Nieuwenhove, T. Renders, J. Lauwaert, T. De Roo, J. De Clercq, A. Verberckmoes, Biobased resins using lignin and glyoxal. ACS Sustain. Chem. Eng. 8(51), 18789–18809 (2020)

H. Zhang, P. Liu, S.M. Musa, C. Mai, K. Zhang, Dialdehyde cellulose as a bio-based robust adhesive for wood bonding. ACS Sustain. Chem. Eng. 7(12), 10452–10459 (2019)

P. Li, Y. Wu, Y. Zhou, Y. Zuo, Preparation and characterization of resorcinol-dialdehyde starch-formaldehyde copolycondensation resin adhesive. Int. J. Biol. Macromol. 127, 12–17 (2019)

N.A. Aziz, A.F.A. Latip, L.C. Peng, N.H.A. Latif, N. Brosse, R. Hashim, M.H. Hussin, Reinforced lignin-phenol-glyoxal (LPG) wood adhesives from coconut husk. Int. J. Biol. Macromol. 141, 185–196 (2019)

A.N. Wilson, M.J. Price, C. Mukarakate, R. Katahira, M.B. Griffin, J.R. Dorgan, J. Olstad, K.A. Magrini, M.R. Nimlos, Integrated biorefining: coproduction of renewable resol biopolymer for aqueous stream valorization. ACS Sustain. Chem. Eng. 5(8), 6615–6625 (2017)

J. Dai, N. Teng, Y. Peng, Y. Liu, L. Cao, J. Zhu, X. Liu, Biobased benzoxazine derived from daidzein and furfurylamine: microwave-assisted synthesis and thermal properties investigation. Chem. Sus. Chem. 11(18), 3175–3183 (2018)

M. Han, S. You, Y. Wang, K. Zhang, S. Yang, Synthesis of highly thermally stable daidzein-based main-chain-type benzoxazine resins. Polymers-Basel. 11(8), 1341 (2019)

K. Zhang, Y. Liu, M. Han, P. Froimowicz, Smart and sustainable design of latent catalyst-containing benzoxazine-bio-resins and application studies. Green Chem. 22(4), 1209–1219 (2020)

B. Hao, R. Yang, K. Zhang, A naringenin-based benzoxazine with an intramolecular hydrogen bond as both a thermal latent polymerization additive and property modifier for epoxy resins. RSC Adv. 10(43), 25629–25638 (2020)

Y. Du, G. Zhao, G. Shi, Y. Wang, W. Li, S. Ren, Effect of crosslink structure on mechanical properties, thermal stability and flame retardancy of natural flavonoid based epoxy resins. Eur. Polym. J. 162, 110898 (2022)

Y. Oh, K.M. Lee, D. Jung, J.A. Chae, H.J. Kim, M. Chang, J.J. Park, H. Kim, Sustainable, naringenin-based thermosets show reversible macroscopic shape changes and enable modular recycling. Thermosets show reversible macroscopic shape changes and enable modular recycling. ACS. Macro. Lett. 8(3), 239–244 (2019)

J. Dai, Y. Peng, N. Teng, Y. Liu, C. Liu, X. Shen, S. Mahmud, J. Zhu, X. Liu, High-performing and fire-resistant biobased epoxy resin from renewable sources. ACS Sustain. Chem. Eng. 6(6), 7589–7599 (2018)

C. Xu, Y. Xu, M. Chen, Y. Zhang, J. Li, Q. Gao, S.Q. Shi, Soy protein adhesive with bio-based epoxidized daidzein for high strength and mildew resistance. Chem. Eng. J. 390, 124622 (2020)

C. Ma, J. Li, Synthesis of an organophosphorus flame retardant derived from daidzein and its application in epoxy resin. Compos. Part B-Eng. 178, 107471 (2019)

Acknowledgements

The work was supported by National Natural Science Foundation of China, Innovative and Entrepreneurial Building Team Project of Jiangsu Province and New Green Materials Project of Hangmo New Materials Group Co., Ltd. The authors wish to express their appreciation to the Analytical Center at Jiangsu University for the measurements of samples.

Funding

National Natural Science Foundation of China (No. 20207003, No. 20704019, No. 51603093), Innovative and Entrepreneurial Building Team Project of Jiangsu Province (No. 2015026), Zhejiang South Taihu Lake Elite Program Leading Innovation Team Project (202001).

Author information

Authors and Affiliations

Contributions

Yuan Qin and Chunyu Xu wrote the main manuscript text. Zhenguo Hu, Yimiao Zhang and Yufei Jia participated in a part of the experimental works. Fuliang Meng, Songjun Li and Xinhua Yuan guided the design work of the scientific research program. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Conflict of Interests

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qin, Y., Meng, F., Xu, C. et al. Preparation and Performance of Novel Flavonoid Phenols-Based Biomass-Modified Phenol Formaldehyde Resins. J Inorg Organomet Polym 33, 1817–1829 (2023). https://doi.org/10.1007/s10904-023-02619-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02619-7