Abstract

Biobased polymers have become one of the substitutes of petro-products, which can address the issue of fossil resource shortage and environmental pollution. In this work, bio-oil–formaldehyde–glucose (BFG) resins were prepared via a three-step method, in which furfural as cross-linking agent was loading via phenolation, hydroxymethylation and copolymerization, respectively. The effect of glucose content and furfural loading time on the performance of BFG resins had been studied in detail. Thermal stability of BFG resins was analyzed by simultaneous thermal analyzer (STA). The chemical structure of the BFG resins was characterized by 1H NMR and 13C NMR techniques. BFG resin with furfural loading via phenolation step (named BFG_P) was synthesis, which the total substitution rate of petro-chemicals by biobased raw materials for phenolic resin was reached 95.28%. The dry strength of BFG_P was 1.76 MPa. The results showed that furfural and bio-oil were benefited to the thermal stability of the BFG resins in the first and second stages. The mechanism of furfural regulating the dry strength of the BFG resins may be close to the number of cross-linking units, whose order was arranged as phenolation > hydroxymethylation > copolymerization. Our results suggested that BFG resins have a good future in the field of wood adhesives.

Graphical abstract

Similar content being viewed by others

References

Martinez-Valencia L, Camenzind D, Wigmosta M, Garcia-Perez M, Wolcott M (2021) Biomass supply chain equipment for renewable fuels production: a review. Biomass Bioenergy 148:106054

Cai W, Luo Z, Zhou J, Wang Q (2021) A review on the selection of raw materials and reactors for biomass fast pyrolysis in China. Fuel Process Technol 221:106919

Isikgor FH, Becer CR (2015) Lignocellulosic biomass: a sustainable platform for the production of bio-based chemicals and polymers. Polym Chem 6:4497–4559

Kunaver M, Medved S, Čuk N, Jasiukaitytė E, Poljanšek I, Strnad T (2010) Application of liquefied wood as a new particle board adhesive system. Bioresour Technol 101:1361–1368

Jin Y, Cheng X, Zheng Z (2010) Preparation and characterization of phenol-formaldehyde adhesives modified with enzymatic hydrolysis lignin. Bioresour Technol 101:2046–2048

Yu Y, Wang Y, Xu P, Chang J (2018) Preparation and characterization of phenol foam modified with bio-oil. Materials 11:2228

Joseph F, Stanzione I, Giangiulio PA, Sadler JM, Scala JJL, Wool RP (2013) Lignin-based bio-oil mimic as biobased resin for composite applications. ACS Sustain Chem Eng 1:419–426

Ipakchi H, Shegeft A, Rezadoust AM, Zohuriaan-Mehr MJ, Kabiri K, Sajjadi S (2020) Bio-resourced furan resin as a sustainable alternative to petro-resourced phenolic resin for making GFR polymer composites. Iran Polym J 29:287–299

Zheng J, Zhu Y, Zhu M, Sun G, Sun R (2018) Life cycle assessment and techno-economic analysis of the utilization of bio-oil components for the production of three chemicals. Green Chem 20:3287–3301

Effendi A, Gerhauser H, Bridgwater AV (2008) Production of renewable phenolic resins by thermochemical conversion of biomass: a review. Renew Sust Energ Rev 12:2092–2116

Zhang Y, Yuan Z, Xu C (2016) Sustainable bio-phenol-hydroxymethylfurfural resins using phenolated de-polymerized hydrolysis lignin and their application in bio-composites. Ind Crop Prod 79:84–90

Adhikari S, Auad M, Via B, Shah A, Patil V (2020) Production of novolac resin after partial substitution of phenol from bio-oil. Trans ASABE 63:901–912

Shudo Y, Izumi A, Hagita K, Nakao T, Shibayama M (2017) Structure-mechanical property relationships in crosslinked phenolic resin investigated by molecular dynamics simulation. Polymer 116:506–514

Choi G, Oh S, Lee S, Kim J (2015) Production of bio-based phenolic resin and activated carbon from bio-oil and biochar derived from fast pyrolysis of palm kernel shells. Bioresour Technol 178:99–107

Kim J (2015) Production, separation and applications of phenolic-rich bio-oil—a review. Bioresour Technol 178:90–98

Krutof A, Hawboldt K (2016) Blends of pyrolysis oil, petroleum, and other bio-based fuels: a review. Renew Sustain Energ Rev 59:406–419

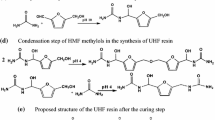

Cheng Y, Sui G, Liu H, Wang X, Yang X, Wang Z (2018) Preparation of highly phenol substituted bio-oil–phenol–formaldehyde adhesives with enhanced bonding performance using furfural as crosslinking agent. J Appl Polym Sci 135:46995

Sui G, Cheng Y, Yang X, Wang X, Wang Z (2019) Use of sustainable glucose and furfural in the synthesis of formaldehyde-free phenolic resole resins. J Appl Polym Sci 136:47732

Songur A, Ozen OA, Sarsilmaz M (2010) The toxic effects of formaldehyde on the nervous system. Rev Environ Contam Toxicol 203:105–118

Jia L, Chu J, Li J, Ren J, Li D (2020) Formaldehyde and VOC emissions from plywood panels bonded with bio-oil phenolic resins. Environ Pollut 264:114819

Li RJ, Gutierrez J, Chung Y, Frank CW, Billington SL, Sattely ES (2018) A lignin-epoxy resin derived from biomass as an alternative to formaldehyde-based wood adhesives. Green Chem 20:1459–1466

Pramudya I, Kim C, Chung H (2018) Synthesis, adhesion control of glucose-based bioadhesive via strain-promoted azide-alkyne cycloaddition. Polym Chem 9:3638–3650

Rapi Z, Szolnoki B, Bakó P, Niedermann P, Toldy A, Bodzay B, Keglevich G, Marosi G (2015) Synthesis and characterization of biobased epoxy monomers derived from d-glucose. Eur Polym J 67:375–382

Christiansen AW (1989) In: Hemingway RW, Conner AH, Branham SJ (eds) Adhesives from renewable resources, vol 385, ACS Symposium Series, ACS, Washington DC, USA, pp 370–386

Wang M, Yuan Z, Cheng S, Leitch M, Xu CC (2010) Synthesis of novolac-type phenolic resins using glucose as the substitute for formaldehyde. J Appl Polym Sci 118:1191–1197

Zhang Y, Yuan Z, Xu C (2015) Engineering biomass into formaldehyde-free phenolic resin for composite materials. AIChE J 61:1275–1283

Zhang Y, Ferdosian F, Yuan Z, Xu CC (2017) Sustainable glucose-based phenolic resin and its curing with a DGEBA epoxy resin. J Taiwan Inst Chem E 71:381–387

Zhang W, Ma Y, Wang C, Li S, Zhang M, Chu F (2013) Preparation and properties of lignin-phenol-formaldehyde resins based on different biorefinery residues of agricultural biomass. Ind Crop Prod 43:326–333

Khan MA, Ashraf SM, Malhotra VP (2004) Eucalyptus bark lignin substituted phenol formaldehyde adhesives: a study on optimization of reaction parameters and characterization. J Appl Polym Sci 92:3514–3523

Lee W, Chang K, Tseng I (2012) Properties of phenol-formaldehyde resins prepared from phenol-liquefied lignin. J Appl Polym Sci 124:4782–4788

Khan MA, Ashraf SM (2007) Studies on thermal characterization of lignin substituted phenol formaldehyde resin as wood adhesives. J Therm Anal Calorim 89:993–1000

Zhao J, Zhang J, Wang L, Li J, Feng T, Fan J, Chen L, Gu J (2020) Superior wave-absorbing performances of silicone rubber composites via introducing covalently bonded SnO2@MWCNT absorbent with encapsulation structure. Compos Commun 22:100486

Tang L, Zhang J, Gu J (2021) Random copolymer membrane coated PBO fibers with significantly improved interfacial adhesion for PBO fibers/cyanate ester composites. Chin J Aeronaut 34:659–668

Oliveira FB, Gardrat C, Enjalbal-Goubet C, Frollini E, Castellan A (2008) Phenol-furfural resins to elaborate composites reinforced with sisal fibers-molecular analysis of resin and properties of composites. J Appl Polym Sci 109:2291–2303

Fan D, Chang J, Li J, An M, Zhang L (2009) 13C-NMR study on the structure of phenol-urea-formaldehyde resins prepared by methylolureas and phenol. J Appl Polym Sci 112:2195–2202

Li JJ, Zhang JZ, Zhang SF, Gao QA, Li JZ, Zhang W (2018) Alkali lignin depolymerization under eco-friendly and cost-effective NaOH/urea aqueous solution for fast curing bio-based phenolic resin. Ind Crop Prod 120:25–33

Chao W, Yang X, Zhou Y, Zhu Y, Wang Z (2017) Lignin impacts on the preparation of phenolic-resin/lignin block copolymer resin and the reaction mechanism. Chem J Chin Univ 38:312–317 (In Chinese)

Acknowledgements

This work was partly supported by the National Nature Science Foundation of China (No. 21763019), the Science and Technology Project of the Education Department of Jiangxi Province (GJJ161238) and the Doctoral Research Start-up Funding of Nanchang Normal University (NSBSJJ2019003 and NSBSJJ2019005).

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cheng, Y., Sui, G. Synthesis and regulation mechanism of bio-oil–glucose phenolic resin using furfural as cross-linking agent. Iran Polym J 31, 619–628 (2022). https://doi.org/10.1007/s13726-022-01022-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01022-2