Abstract

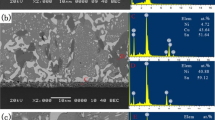

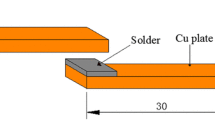

In order to investigate the effect of Bi on the microstructure of Sn–Ag–Cu/Ni interface, the shear forces of Sn–1.0Ag–0.5Cu–xBi (x = 0, 1, 1.5, 2, 2.5, 3 wt%) joints after various aging treatments were tested, and the fracture behavior of joints were researched simultaneously. The results show that a prismatic (Cu, Ni)6Sn5 layer and a slender rod-shaped (Ni, Cu)3Sn4 layer are formed between the Sn–Ag–Cu solder and the Ni substrate after reflow at 250 °C for 60 s, and (Ni, Cu)3Sn4 is close to the side of the substrate, while (Cu, Ni)6Sn5 is close to the side of the solder. The thickness of IMCs increases with the extend of aging time, but the IMC layers become thinner and the grain size becomes smaller with the Bi addition. It is also found that the diffusion rate of interfacial elements is reduced, thus, the growth activation energy of IMCs is enhanced with the increase of Bi addition. Furthermore, with the increase of Bi content, the shear forces of solder joints are improved. However, due to the brittleness of Bi, the shear fracture mode changes from ductile fracture to ductile–brittle mixed fracture when the Bi content is more than 1.5 wt%. Combined with the shear force, fracture morphology and IMC microstructure, the optimal amount of Bi addition is about 1.5 wt% in this study.

Similar content being viewed by others

Data availability

Can be provided when required.

References

T.T. Mattila, J.K. Kivilahti, Reliability of lead-free interconnections under consecutive thermal and mechanical loadings. J. Electron. Mater. 35, 250–256 (2005)

J.X. Wang, H. Nishikawa, Impact strength of Sn–3.0Ag–0.5Cu solder bumps during isothermal aging. Microelectron. Reliab. 54, 1583–1591 (2014)

L. Zhang, Z.Q. Liu, Inhibition of intermetallic compounds growth at Sn–58Bi/Cu interface bearing CuZnAl memory particles (2–6 μm). J. Mater. Sci.: Mater. Electron. 31, 2466–2480 (2020)

R.A.M. Anuar, S.A. Osman, The formation of intermetallic layer structure of SAC405/Cu and SAC405/ENImAg solder joint interfaces. Solder. Surf. Mt. Technol. 33, 75–85 (2020)

H.F. Zou, Z.F. Zhang, Application of electron backscatter diffraction to the study on orientation distribution of intermetallic compounds at heterogeneous interfaces (Sn/Ag and Sn/Cu). J. Appl. Phys. 108, (2010)

R. Zhang, F. Guo, J. Liu, H. Shen, F. Tai, Morphology and growth of intermetallics at the interface of Sn-based solders and Cu with different surface finishes. J. Electron. Mater. 38, 241–251 (2008)

F.C. Tai, K.J. Wang, J.G. Duh, Application of electroless Ni–Zn–P film for under-bump metallization on solder joint. Scr. Mater. 61, 748–751 (2009)

T. Kadoguchi, N. Take, K. Yamanaka, S. Nagao, K. Suganuma, Highly thermostable joint of a Cu/Ni–P plating/Sn–0.7Cu solder added with Cu balls. J. Mater. Sci. 52, 3244–3254 (2017)

M.Y. Xiong, L. Zhang, Interface reaction and intermetallic compound growth behavior of Sn-Ag-Cu lead-free solder joints on different substrates in electronic packaging. J. Mater. Sci. 54, 1741–1768 (2019)

J. Wu, S.B. Xue, J.W. Wang, Effect of Pr addition on properties and Sn whisker growth of Sn–0.3Ag–0.7Cu low-Ag solder for electronic packaging. J. Mater. Sci.: Mater. Electron. 28, 10230–10244 (2017)

Y. Gu, X.C. Zhao, Y. Li, Effect of nano-Fe2O3 additions on wettability and interfacial intermetallic growth of low-Ag content Sn–Ag–Cu solders on Cu substrates. J. Alloys Compd. 627, 39–47 (2015)

J. Wu, S.B. Xue, J.W. Wang, Enhancement on the high-temperature joint reliability and corrosion resistance of Sn–0.3Ag–0.7Cu low-Ag solder contributed by Al2O3 Nanoparticles (0.12 wt%). J. Mater. Sci.: Mater. Electron. 29, 19663–19677 (2018)

M.Y. Xiong, L. Zhang, P. He, Stress analysis and structural optimization of 3-D IC package based on the Taguchi method. Solder. Surf. Mt. Technol. 32, 42–47 (2020)

F.J. Wang, H. Chen, Y. Huang, Interfacial behavior and joint strength of Sn–Bi solder with solid solution compositions. J. Mater. Sci.: Mater. Electron. 29, 11409–11420 (2018)

Z.M. Lai, D. Ye, Effect of Al on the microstructure and properties of Sn–0.7Cu solder alloy. J. Mater. Sci.: Mater. Electron. 27, 1177–1183 (2016)

X.L. Wu, J.W. Wu, X.J. Wang, Effect of In addition on microstructure and mechanical properties of Sn-40Bi alloys. J. Mater. Sci. 55, 3092–3106 (2019)

J. Wu, S.B. Xue, J. Wang, Comparative studies on microelectronic reliability issue of Sn whisker growth in Sn-0.3Ag-0.7Cu-1Pr solder under different environments. Microelectron. Reliab. 79, 124–135 (2017)

J. Zolhafizi, O.S. Azlina, The effect of Bismuth on intermetallics growth between lead-free solders and electroless nickel immersion silver (ENIMAG) surface Finish. Key Eng. Mater. 796, 183–188 (2019)

J.W. Yoon, S.W. Kim, S.B. Jung, IMC morphology, interfacial reaction and joint reliability of Pb-free Sn–Ag–Cu solder on electrolytic Ni BGA substrate. J. Alloys Compd. 392, 247–252 (2005)

W.C. Luo, C.E. Ho, J.Y. Tsai, Solid-state reactions between Ni and Sn–Ag–Cu solders with different Cu concentrations. Mater. Sci. Eng. A 396, 385–391 (2005)

J.W. Yoon, B.I. Noh, J.H. Yoon, Sequential interfacial intermetallic compound formation of Cu6Sn5 and Ni3Sn4 between Sn-Ag-Cu solder and ENEPIG substrate during a reflow process. J. Alloys Compd. 509, L153–L156 (2011)

M.A.R. Adawiyah, S.A. Amirul, O.S. Azlina, H. Syafiq, Impact of multiple reflow on intermetallic compound of nickel-doped tin-silver-copper on ENImAg substrate. Materwiss Werksttech. 51, 780–786 (2020)

L.Z. Yang, W. Zhou, Y. Ma, Effects of Ni addition on mechanical properties of Sn58Bi solder alloy during solid state aging. Mater. Sci. Eng. A 667, 368–375 (2016)

D.K. Mu, S.D. McDonald, J. Read, Critical properties of Cu6Sn5 in electronic devices: recent progress and a review. Curr. Opin. Solid State Mater. Sci. 20, 55–76 (2016)

D.G. Kim, S.B. Jung, Interfacial reactions and growth kinetics for intermetallic compound layer between In-48Sn solder and bare Cu substrate. J. Alloys Compd. 386, 151–156 (2005)

X.W. Hu, Z.R. Ke, Growth behavior of interfacial Cu–Sn intermetallic compounds of Sn/Cu reaction couples during dip soldering and aging. J. Mater. Sci.: Mater. Electron. 25, 936–945 (2013)

R. Sayyadi, H. Naffakh-Moosavy, The role of intermetallic compounds in controlling the microstructural, physical and mechanical properties of Cu-Sn-Ag-Cu-Bi-Cu solder joints. Sci. Rep. 9, 8389 (2019)

X.W. Hu, Y. Li, Y. Liu, Microstructure and shear strength of Sn37Pb/Cu solder joints subjected to isothermal aging. Microelectron. Reliab. 54, 1575–1582 (2014)

K.E. Yazzie, H.E. Fei, H. Jiang, N. Chawla, Rate-dependent behavior of Sn alloy–Cu couples: effects of microstructure and composition on mechanical shock resistance. Acta Mater. 60, 4336–4348 (2012)

Y. Liu, F. Sun, Y. Liu, X. Li, Effect of Ni, Bi concentration on the microstructure and shear behavior of low-Ag SAC–Bi–Ni/Cu solder joints. J. Mater. Sci.: Mater. Electron. 25, 2627–2633 (2014)

X.W. Hu, T. Xu, L.M. Keer, Y. Li, Microstructure evolution and shear fracture behavior of aged Sn3Ag0.5Cu/Cu solder joints. Mater. Sci. Eng. A 673, 167–177 (2016)

Acknowledgements

This work was carried out with the support of the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (18KJA460002), and the Natural Science Foundation of Jiangsu Province (BX2019071, BX2020079).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J., Su, H., Mu, D. et al. Growth behavior of IMCs in Sn–1.0Ag–0.5Cu–xBi/Ni joints during isothermal aging. J Mater Sci: Mater Electron 32, 20777–20792 (2021). https://doi.org/10.1007/s10854-021-06591-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06591-1