Abstract

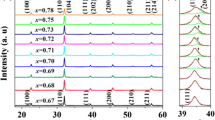

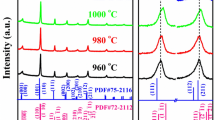

The chemical composition and phase structure of (1−x)BiFeO3−xBaTiO3 (BF–xBT) ceramics near morphotropic phase boundary (MPB) are controversial so far. Particularly, no report mentioned BT content dependence of phase ratio of BF–xBT ceramics near MPB. Herein, BF–xBT (x = 0.24–0.38) ceramics with pure perovskite structure and dense microstructure were prepared by conventional sintering technics. The phase composition, electric resistivity, dielectric, ferroelectric and piezoelectric properties of the ceramics were systematically investigated. The results showed that the phase structure of the ceramics transforms from rhombohedral (R) to pseudocubic (pC) with increasing BT content, and the MPB with R-pC phase coexistence was determined in the range of 0.28 ≤ x ≤ 0.33. In addition, as BT content increases for the ceramics near MPB, the phase fraction of R decreases gradually from 75.3% for BF–0.28BT to 36.9% for BF–0.33BT. Especially for BF–0.31BT ceramics, the phase fraction of R (49.1%) and pC (50.9%) are almost equal to each other. Enhanced piezoelectricity and ferroelecricity were attained in the ceramics near MPB. Owing to more proper R/pC phase ratio and strong ferroelectricity, the best piezoelectric coefficient d33 = 190 pC/N was achieved in BF–0.31BT ceramics. This work revealed the relationship between chemical composition, phase structure and piezoelectric property of BF–BT piezoceramics near MPB, which is helpful to further improve the piezoelectric property of BF–BT via optimizing phase structure and/or composition engineering.

Similar content being viewed by others

Data availability

The data and material will be provided under reasonable request.

References

T. Zheng, J. Wu, D. Xiao, J. Zhu, Prog. Mater. Sci. 98, 552–624 (2018)

G.H. Haertling, J. Am. Ceram. Soc. 82, 797–818 (1999)

E. Cross, Nature 432, 24–25 (2004)

T. Rojac, A. Bencan, B. Malic, G. Tutuncu, J.L. Jones, J.E. Daniels, D. Damjanovic, J. Am. Ceram. Soc. 97, 1993–2011 (2014)

V.V. Shvartsman, W. Kleemann, R. Haumont, J. Kreisel, Appl. Phys. Lett. 90, 172115 (2007)

T. Rojac, M. Kosec, B. Budic, N. Setter, D. Damjanovic, J. Appl. Phys. 108, 74107 (2010)

S.H. Song, Q.S. Zhu, L.Q. Weng, V.R. Mudinepalli, J. Eur. Ceram. Soc. 35, 131–138 (2015)

G.L. Yuan, S.W. Or, Y.P. Wang, Z.G. Liu, J.M. Liu, Solid State Commun. 138, 76–81 (2006)

J. Wu, Z. Fan, D. Xiao, J. Zhu, J. Wang, Prog. Mater. Sci. 84, 335–402 (2016)

W.M. Zhu, H.Y. Guo, Z.G. Ye, Phys. Rev. B 78, 014401 (2008)

M.M. Kumar, A. Srinivas, S.V. Suryanarayana, J. Appl. Phys. 87, 885–862 (2000)

Y. Wei, X. Wang, J. Zhu, X. Wang, J. Jia, J. Am. Ceram. Soc. 96, 3163–3168 (2013)

M.H. Lee, D.J. Kim, J.S. Park, S.W. Kim, T.K. Song, M.H. Kim, W.J. Kim, D. Do, I.K. Jeong, Adv. Mater. 27, 6976–6982 (2015)

S. Kim, G.P. Khanal, H.W. Nam, I. Fujii, S. Ueno, C. Moriyoshi, Y. Kuroiwa, S. Wada, J. Appl. Phys. 122, 164105 (2017)

L.F. Zhu, B.P. Zhang, Z.C. Zhang, J. Mater. Sci. Mater. Electron. 29, 2307–2315 (2018)

Z.Z. Ma, Z.M. Tian, J.Q. Li, C.H. Wang, S.X. Huo, H.N. Duan, S.L. Yuan, Solid State Sci. 13, 2196–2200 (2011)

Q.Q. Wang, Z. Wang, X.Q. Liu, X.M. Chen, J. Am. Ceram. Soc. 95, 670–675 (2012)

M.I. Morozov, M. Einarsrud, T. Grande, Appl. Phys. Lett. 104, 122905 (2014)

Y. Ma, X.M. Chen, J. Appl. Phys. 105, 054107 (2009)

C. Chen, Y. Wang, X. Jiang, N. Tu, Y. Chen, S. Zhou, X. Xia, Z. Shen, H. Luo, J. Am. Ceram. Soc. 102, 4306–4313 (2019)

C. Chen, X. Zhao, Y. Wang, H. Zhang, H. Deng, X. Li, X. Jiang, X. Jiang, H. Luo, Appl. Phys. Lett. 108, 022903 (2016)

X. Lv, J. Zhu, D. Xiao, X.X. Zhang, J. Wu, Chem. Soc. Rev. 49, 671–707 (2020)

H. Tao, H. Wu, Y. Liu, Y. Zhang, J. Wu, F. Li, X. Lyu, C. Zhao, D. Xiao, J. Zhu, S.J. Pennycook, J. Am. Chem. Soc. 141, 13987–13994 (2019)

S.O. Leontsev, R.E. Eitel, J. Am. Ceram. Soc. 92, 2957–2961 (2009)

Y. Sun, H. Yang, S. Guan, Y. Cao, M. Jiang, X. Liu, Q. Chen, M. Li, J. Xu, J. Alloy. Comp. 819, 153058 (2020)

C. Zhou, A. Feteira, X. Shan, H. Yang, Q. Zhou, J. Cheng, W. Li, H. Wang, Appl. Phys. Lett. 101, 032901 (2012)

T. Zheng, Z. Jiang, J. Wu, Dalton Trans. 45, 11277–11285 (2016)

Z. Liu, T. Zheng, C. Zhao, J. Wu, J. Mater. Sci. Mater. Electron. 28, 13076–13083 (2017)

H. Yang, C. Zhou, X. Liu, Q. Zhou, G. Chen, W. Li, H. Wang, J. Eur. Ceram. Soc. 33, 1177–1183 (2013)

D. Lin, Q. Zheng, Y. Li, Y. Wan, Q. Li, W. Zhou, J. Eur. Ceram. Soc. 33, 3023–3036 (2013)

L.F. Zhu, B.P. Zhang, J.Q. Duan, B.W. Xun, N. Wang, Y.C. Tang, G.L. Zhao, J. Eur. Ceram. Soc. 38, 3463–3471 (2018)

S. Cheng, L. Zhao, B.P. Zhang, K.K. Wang, Ceram. Int. 45, 10438–10447 (2019)

L. Lutterotti, MAUD, Material Analysis Using Diffraction (2019). http://www.ing.unitn.it/~maud/index.html. Accessed 20 July 2019

L. Luo, L. Zhou, X. Zou, Q. Zheng, D. Lin, J. Mater. Sci. Mater. Electron. 26, 9451–9462 (2015)

R.D. Shannon, Acta Cryst. A32, 751–767 (1976)

D.I. Woodward, I.M. Reaney, R.E. Eitel, C.A. Randall, J. Appl. Phys. 94, 3313–3318 (2003)

Y.P. Guo, K. Kakimoto, H. Ohsato, Solid State Commun. 129, 279–284 (2004)

F. Yan, P. Bao, Y.N. Wang, Appl. Phys. Lett. 83, 4384–4386 (2003)

V. Bobnar, J. Bernard, M. Kosec, Appl. Phys. Lett. 85, 994–996 (2004)

D. Damjanovic, J. Am. Ceram. Soc. 88, 2663–2676 (2005)

J. Wei, D. Fu, J. Cheng, J. Chen, J. Mater. Sci. 52, 10726–10737 (2017)

A.K. Pradhan, K. Zhang, D. Hunter, J.B. Dadson, G.B. Loutts, P. Bhattacharya, R. Katiyar, J. Zhang, D.J. Sellmyer, U.N. Roy, Y. Cui, A. Burger, J. Appl. Phys. 97, 093903 (2005)

L. Jin, F. Li, S. Zhang, D.J. Green, J. Am. Ceram. Soc. 97, 1–27 (2014)

D. Lin, K.W. Kwok, H.L.W. Chan, J. Alloys. Compd. 461, 273–278 (2008)

Y. Hiruma, H. Nagata, T. Takenaka, Jpn. J. Appl. Phys. 45, 7409–7412 (2006)

F. Li, D. Lin, Z. Chen, Z. Cheng, J. Wang, C.C. Li, Z. Xu, Q. Huang, X. Liao, L.Q. Chen, T.R. Shrout, S. Zhang, Nat. Mater. 17, 349–354 (2018)

Acknowledgements

This work was supported by The R & D Projects in Key Fields of Guangdong Province (Grant Nos. 2020B0109380001; 2019B040403004; 2019B040403006); Science and Technology Planning Project of Guangxi Zhuang Autonomous Region (Grant No. AA18118034); National Natural Science Foundation of China (Grant Nos. 51577070 and U1601208); Science and Technology Program of Guangzhou (Grant No. 201704030095).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yi, W., Lu, Z., Liu, X. et al. Relationship between chemical composition, phase structure and piezoelectric property of BiFeO3–BaTiO3 ceramics near morphotropic phase boundary. J Mater Sci: Mater Electron 32, 7719–7728 (2021). https://doi.org/10.1007/s10854-021-05490-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05490-9