Abstract

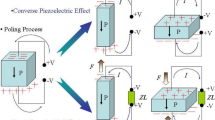

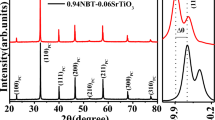

Lead free piezoelectric ceramic K0.5Na0.5NbO3 (KNN) was synthesized by conventional mixed oxide method. The effect of nano CuO additive as the sintering aid, on microstructure and electrical properties of pure KNN ceramics was investigated. Sintering process has a great impact on the piezoelectric properties of lead free piezoelectric ceramics. The results indicated that adding small amount of nano CuO sintering aid reduces the sintering temperature of lead free piezoelectric KNN ceramic to 900 °C, and also leads to excellent densification and proper microstructure. Samples characterization by X-ray diffraction represented that there are no secondary phases for KNN ceramics with CuO additive in the range of 0–2 mol%. The dielectric and piezoelectric properties are strongly modified by the amount of nano CuO additive. A high piezoelectric coefficient (d33) up to 130 pC/N and a dielectric loss <0.008 achieved for the sample with 0.5 mol% nano CuO, sintered at 900 °C for 4 h.

Similar content being viewed by others

References

B. Jaffe, W.R. Cook, H. Jaffe, Piezoelectric Ceramics. (Academic Press, New York, 1971), pp. 1–20

A.D. Sheikh, H.H. Kumar, V.L. Mathe, Solid State Sci. 12, 1534 (2010)

L. Egerton, D.M. Dillon, J. Am. Ceram. Soc. 42, 438 (1959)

E. Ringgaard, T. Wurlitzer, W.W. Wolny, Ferroelectrics 319, 97 (2005)

W. Wu, M. Chen, J. Li, Y. Ding, C. Liu, J. Alloys Compd. 670, 128 (2016)

T. Maeda, N. Takiguchi, M. Ishikawa, T. Hemsel, T. Morita, Mater. Lett. 64, 125 (2010)

J.F. Li, K. Wang, B.P. Zhang, L.M. Zhang, J. Am. Ceram. Soc. 89, 706 (2006)

R.E. Jaeger, L. Egerton, J. Am. Ceram. Soc. 45, 209 (1962)

J. Zhao, H. Du, S. Qu, J. Wang, H. Zhang, Y. Yang, Z. Xu, J. Alloys Compd. 509, 3537 (2011)

X. Yan, B. Peng, X. Lu, Q. Dong, W. Li, J. Alloys Compd. 653, 523 (2015)

R.A. Bucur, I. Badea, A.I. Bucur, S. Novaconi, J. Alloys Compd. 630, 43 (2015)

W. Wu, M. Chen, Y. Ding, C. Liu, J. Alloys Compd. 588, 496 (2014)

F. Rubio Marcos, J.J. Romero, M.G. Navarro Rojero, J.F. Fernandez, J. Eur. Ceram. Soc. 29, 3045 (2009)

E. Li, H. Kakemoto, S. Wada, T. Tsurumi, J. Eur. Ceram. Soc. 90, 1787 (2007)

D. Lin, K.W. Kwok, H.L.W. Chan, J. Appl. Phys. 103, 064105 (2008)

R. Hyati, A. Barzegar, Mater. Sci. Eng. B 172, 121 (2010)

M.R. Saeri, A. Barzegar, H. Ahmadi Moghadam, Ceram. Int. 37, 3083 (2011)

C.A. Randall, A. Kelnberger, G.Y. Yang, R.E. Eitel, T.R. Shrout, J. Electroceram. 14, 177 (2005)

I.T. Seo, H.Y. Park, N.V. Dung, M.K. Choi, S. Nahm, H.G. Lee, B.H. Choi, IEEE Trans. Ultrason. Ferroelectr. Freq. Control 56, 2337 (2009)

H.Y. Park, J.Y. Choi, M.K. Choi, K.H. Cho, H.G. Lee, H.W. Kang, S. Nahm, J. Am. Ceram. Soc. 91, 2374 (2008)

E. Alkoy, M. Papila, Microstruct. Ceram. Int. 36, 1921 (2010)

D. Lin, K.W. Kwok, H.L.W. Chan, J. Phys. D 41, 045401 (2008)

M.W. Barsoum, Fundamentals of Ceramics. (CRC Press, New York, 2002), pp. 334–335

S. Su, R. Zuo, X. Wang, L. Li, Mater. Res. Bull. 45, 124 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmadi Moghadam, H., Barzegar, A. Low-temperature sintering of K0.5Na0.5NbO3 lead free ceramics using nano CuO sintering aid. J Mater Sci: Mater Electron 28, 13161–13167 (2017). https://doi.org/10.1007/s10854-017-7151-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7151-8