Abstract

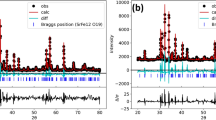

M-type hexaferrites; barium hexaferrite BaFe12O19 and strontium hexaferrite SrFe12O19 powders have been successfully prepared via the co-precipitation method using 5 M sodium carbonate solution as alkali. Effects of the molar ratio and the annealing temperature on the crystal structure, crystallite size, microstructure and the magnetic properties of the produced powders were systematically studied. The results indicated that a single phase of barium hexaferrite was obtained at Fe3+/Ba2+ molar ratio 12 annealed at 800–1,200 °C for 2 h whereas the orthorhombic barium iron oxide BaFe2O4 phase was formed as a impurity phase with barium M-type ferrite at Fe3+/Ba2+ molar ratio 8. On the other hand, a single phase of strontium hexaferrite was produced with the Fe3+/Sr2+ molar ratio to 12 at the different annealing temperatures from 800 to 1,200 °C for 2 h whereas the orthorhombic strontium iron oxide Sr4Fe6O13 phase was formed as a secondary phase with SrFe12O19 phase at Fe3+/Sr2+ molar ratio of 9.23. The crystallite sizes of the produced nanopowders were increased with increasing the annealing temperature and the molar ratios. The microstructure of the produced single phase M-type ferrites powders displayed as a hexagonal-platelet like structure. A saturation magnetization (53.8 emu/g) was achieved for the pure barium hexaferrite phase formed at low temperature 800 °C for 2 h. On the other hand, a higher saturation magnetization value (M s = 85.4 emu/g) was obtained for the strontium hexaferrite powders from the precipitated precursors synthesized at Fe3+/Sr2+ molar ratio 12 and thermally treated at 1,000 °C for 2 h.

Similar content being viewed by others

References

M.M. Hessien, M. Radwan, M.M. Rashad, J. Anal. Appl. Pyrolysis 78, 282 (2007)

M.J. Iqbal, S. Farooq, J. Alloys Compd. 502, 560 (2010)

M.N. Ashiq, M.J. Iqbal, I.H. Gul, J. Mag. Mag. Mater. 323, 259 (2011)

M. Radwan, M.M. Rashad, M.M. Hessien, J. Mater. Proc. Technol. 181, 106 (2007)

M.M. Rashad, M. Radwan, M.M. Hessien, J. Alloys Compd. 453, 304 (2008)

M.M. Hessien, M.M. Rashad, K. El-Barawy, J. Mag. Mag. Mater. 320, 336 (2008)

Z.F. Zi, Y.P. Sun, X.B. Zhu, Z.R. Yang, J.M. Dai, W.H. Song, J. Mag. Mag. Mater. 320, 2746 (2008)

N. Langhof, D. Seifert, M. Göbbels, J. Töpfer, J. Solid State Chem. 182, 2409 (2009)

S.E. Jacobo, L. Civale, M.A. Blesa, J. Mag. Mag. Mater. 260, 37 (2003)

P. Shepherd, K.K. Mallick, R.J. Green, J. Mag. Mag. Mater. 311, 683 (2007)

V.N. Dhage, M.L. Mane, A.P. Keche, C.T. Birajdar, K.M. Jadhav, Physica B Condens. Matter 406, 789 (2011)

E.C. Stoner, E.P. Wohlfarh, IEEE Trans. Magn. Mag. 27, 3475 (1991)

G. Mu, X. Pan, N. Chen, K. Gan, M. Gu, Mater. Res. Bull. 43, 1369 (2008)

F.-z. Mou, J.-g. Guan, Z.-g. Sun, X.-a. Fan, G.-x. Tong, J. Solid State Chem. 183, 736 (2010)

J. Adnan, A. Safwan, A. Ahmed, B. Mohamed, Inter. J. Nanosci. 9, 575 (2010)

U. Topal, J. Mag. Mag. Mater. 320, 331 (2008)

W. Zhanyong, Z. Liuming, L. Jieli, Q. Huichun, Z. Yuli, F. Yongzheng, J. Minglin, X. Jiayue, J. Mag. Mag. Mater. 320, 336 (2008)

M. Jean, V. Nachbauer, J. Bran, J.M. Le Breton, J. Alloys Compd. 496, 306 (2010)

A. Cochardt, J. Appl. Phys. 34, 1273 (1963)

H. Kojima, in Ferromagnetic Materials, ed. by E. P. Wohlfarth. North-magneto-optical Recording, vol 3 (Amsterdam, Holland, 1982), p. 305

Acknowledgments

This research is financially supported by the Science and Technology Development Fund (STDF), Egypt, Grant No. Project ID 246.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rashad, M.M., Ibrahim, I.A. A novel approach for synthesis of M-type hexaferrites nanopowders via the co-precipitation method. J Mater Sci: Mater Electron 22, 1796–1803 (2011). https://doi.org/10.1007/s10854-011-0365-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-011-0365-2