Abstract

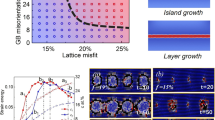

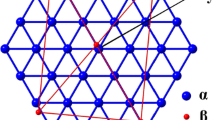

Interfacial solute clustering is an essential step preceding grain boundary (GB) precipitation. Both states, i.e., clusters and precipitates, alter the mechanical, chemical, and corrosion properties of materials. Continuum models cannot capture the atomic details of these phenomena, specifically of the transition from clustering to precipitation. We thus use the structural phase-field crystal (XPFC) model to study the compositional and structural evolution during GB clustering in Al–Cu alloys. The results show that the compositional evolution is dominated by solute segregation to lattice defects at the very beginning and then by confined spinodal decomposition along the GBs. The latter leads to a steep increase in the concentration and then the formation of disordered clusters. This structure acts as a precursor for phase nucleation, just like the decomposed solid solution, and Guinier–Preston zones are the precursors of the thermodynamically stable Al2Cu phase in the interior of grains. Two modes of spinodal decomposition are found. (a) On low-angle tilt GBs, spinodal decomposition occurs at the dislocations that constitute the GB. (b) On high-angle tilt GBs, spinodal decomposition takes place inside the entire GB plane. In either case, the structural transition from the disordered low-dimensional precursor states to an ordered phase state takes place following the compositional enrichment. These results shed light on atomic-scale early-stage GB decomposition and precipitation processes in Al–Cu alloys and enrich our knowledge about the coupling effects between compositional and structural evolution during GB phase transformation phenomena.

taken from Ref. [53]. The polynomial fitting parameters were η = 1.4, χ = 1 and ω = 0.005, while XPFC parameters σMi = 0.6, αi = 0.8, and the reference composition c0 = 0.5

Similar content being viewed by others

References

Seidman DN, Marquis EA, Dunand DC (2002) Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys. Acta Mater 50:4021. https://doi.org/10.1016/S1359-6454(02)00201-X

Rambabu P, Prasad NE, Kutumbarao VV, Wanhill RJH (2017) Aluminium alloys for aerospace applications. Aerospace materials and material technologies, Springer

Esmaeili S, Wang X et al (2003) On the precipitation-hardening behavior of the Al−Mg−Si−Cu alloy AA6111. Metall Mater Trans A 34(13):751. https://doi.org/10.1007/s11661-003-0110-4

Smallman RE, Ngan AHW (1963) Precipitation hardening. Pergamon

Dong Q, Howells A, Lloyd DJ, Gallerneault M, Fallah V (2020) Effect of solidification cooling rate on kinetics of continuous/discontinuous Al3(Sc, Zr) precipitation and the subsequent age-hardening response in cold-rolled AlMgSc(Zr) sheets. Mater Sci Eng, A. https://doi.org/10.1016/j.msea.2019.138693

Wu L, Li Y, Li X, Ma N, Wang H (2020) Interactions between cadmium and multiple precipitates in an Al–Li–Cu alloy: improving aging kinetics and precipitation hardening. J Mater Sci Technol 46:44. https://doi.org/10.1016/j.jmst.2019.11.032

Kwiatkowski A, da Silva D, Ponge ZP et al (2018) Phase nucleation through confined spinodal fluctuations at crystal defects evidenced in Fe–Mn alloys. Nat Commun 9:1137. https://doi.org/10.1038/s41467-018-03591-4

Zhang J, Ii HWG, Bozhilov K, Jin Z (2004) Faulting induced by precipitation of water at grain boundaries in hot subducting oceanic crust. Nature 428:633. https://doi.org/10.1038/nature02475

L’Vov PE, Svetukhin VV (2018) Precipitation kinetics in binary alloys near grain boundaries. Phys Solid State 60:791. https://doi.org/10.1134/S1063783418040200

Belton GR (1976) Langmuir adsorption, the gibbs adsorption isotherm, and interracial kinetics in liquid metal systems. Metall Trans B 7:35. https://doi.org/10.1007/BF02652817

Lei Y, Ito Y, Browning ND, Mazanec TJ (2010) Segregation effects at grain boundaries in fluorite-structured ceramics. J Am Ceram Soc 85:2359. https://doi.org/10.1111/j.1151-2916.2002.tb00460.x

Seah MP, Hondros ED (1973) Grain boundary segregation. Proc R Soc Lond 335:191. https://doi.org/10.2307/2397194

Graux A, Cazottes S, De Castro D et al (2019) Precipitation and grain growth modelling in Ti–Nb microalloyed steels. Materialia. https://doi.org/10.1016/j.mtla.2019.100233

Guttmann AJ, Kim D, Thompson CJ (1977) Critical isotherm of Dyson’s hierarchical model. J Phys A Gen Phys 10:L125. https://doi.org/10.1088/0305-4470/10/6/007

Kwiatkowski A, da Silva G, Leyson MK et al (2017) Confined chemical and structural states at dislocations in Fe–9wt%Mn steels: a correlative TEM-atom probe study combined with multiscale modelling. Acta Mater 124:305. https://doi.org/10.1016/j.actamat.2016.11.013

Zhao H, Frédéric DG, Alisson KdS et al (2018) Segregation assisted grain boundary precipitation in a model Al–Zn–Mg–Cu alloy. Acta Mater. https://doi.org/10.1016/j.actamat.2018.07.003

Kwiatkowski da Silva RDKA, Ponge D, Gault B, Neugebauer J, Raabe D (2019) Thermodynamics of grain boundary segregation, interfacial spinodal and their relevance for nucleation during solid-solid phase transitions. Acta Mater 168:109. https://doi.org/10.1016/j.actamat.2019.02.005

Silva D, Kwiatkowski A, Leyson G, Kuzmina M et al (2017) Confined chemical and structural states at dislocations in Fe–9wt%Mn steels: a correlative TEM-atom probe study combined with multiscale modelling. Acta Mater. 124:305. https://doi.org/10.1016/j.actamat.2016.11.013

Kuzmina M, Herbig M, Ponge D, Sandlobes S, Raabe D (2015) Linear complexions: confined chemical and structural states at dislocations. Science 349:1080. https://doi.org/10.1126/science.aab2633

Raabe D, Herbig M, Sandlobes S et al (2014) Grain boundary segregation engineering in metallic alloys: a pathway to the design of interfaces. Curr Opin Solid State Mater Sci 18:253. https://doi.org/10.1016/j.cossms.2014.06.002

Linlin Li ZL, Kwiatkowski A, da Silva Z, Peng HZ, Gault B, Raabe D (2019) Segregation-driven grain boundary spinodal decomposition as a pathway for phase nucleation in a high-entropy alloy. Acta Mater 178:1. https://doi.org/10.1016/j.actamat.2019.07.052

Kwiatkowski DA, Da Silva Z, Peng G, Inden Y, Lu A, Breen BG, Raabe D (2018) Phase nucleation through confined spinodal fluctuations at crystal defects evidenced in Fe–Mn alloys. Nat Commun 9:1. https://doi.org/10.1038/s41467-018-03591-4

Li L, Li Z, da Silva AK et al (2019) Segregation-driven grain boundary spinodal decomposition as a pathway for phase nucleation in a high-entropy alloy. Acta Mater 178:1. https://doi.org/10.1016/j.actamat.2019.07.052

Kwiatkowski A, da Silva G, Inden AK, Ponge D, Gault B, Raabe D (2018) Competition between formation of carbides and reversed austenite during tempering of a medium-manganese steel studied by thermodynamic-kinetic simulations and atom probe tomography. Acta Mater 147:165. https://doi.org/10.1016/j.actamat.2018.01.022

Zhao JC, Notis MR (1998) Spinodal decomposition, ordering transformation, and discontinuous precipitation in a Cu–15Ni–8Sn alloy. Acta Mater 46:4203. https://doi.org/10.1016/S1359-6454(98)00095-0

Ramanarayan H, Abinandanan TA (2004) Grain boundary effects on spinodal decomposition: II Discontinuous microstructures. Acta Mater 52:921. https://doi.org/10.1016/j.actamat.2003.10.028

Feng B, Yokoi T, Kumamoto A, Yoshiya M, Ikuhara Y, Shibata N (2016) Atomically ordered solute segregation behaviour in an oxide grain boundary. Nat Commun 7:11079. https://doi.org/10.1038/ncomms11079

Lejček P (2013) Effect of solute interaction on interfacial segregation and grain boundary embrittlement in binary alloys. J Mater Sci 48:2574. https://doi.org/10.1007/s10853-012-7048-0

Hersent E, Marthinsen K, Nes E (2013) The effect of solute atoms on grain boundary migration: a solute pinning approach. Metall Mater Trans A 44:3364. https://doi.org/10.1007/s11661-012-1552-3

Furrer P, Gronsky R (1981) Grain boundary precipitation in aluminum alloys: effect of boundary structure. Am Soc Met Metall Soc Aime 12A:121. https://doi.org/10.1007/BF02648516

Hiroaki Kurishita SK (1985) Misorientation dependence of grain boundary. Trans Jpn Inst Met 26:332. https://doi.org/10.2320/matertrans1960.26.332

Oliveira MM, Soares PC, Bueno PR, Leite ER, Longo E, Varela JA (2003) Grain-boundary segregation and precipitates in La2O3 and Pr2O3 doped SnO2·CoO-based varistors. J Eur Ceram Soc 23:1875. https://doi.org/10.1016/s0955-2219(02)00445-4

Das S, Mukherjee M, Pal TK (2015) Effect of grain boundary precipitation and δ-ferrite formation on surface defect of low nickel austenitic stainless steels. Eng Fail Anal 54:90. https://doi.org/10.1016/j.engfailanal.2015.04.010

Moskovkin P, Hou M (2003) Thermal evolution of cluster assembled Ni3Al materials modelled at the atomic scale. Eur Phys J D—At, Mol Opt Phys 27:231. https://doi.org/10.1140/epjd/e2003-00277-3

Malik A, Odqvist J, Höglund L, Hertzman S, Ågren J (2017) Phase-Field modeling of sigma-phase precipitation in 25Cr7Ni4Mo duplex stainless steel. Metall Mater Trans A 48:4914. https://doi.org/10.1007/s11661-017-4214-7

Dong W, Wang Y, Yang K, Chen Z, Lu Y (2011) Phase field simulation of interatomic potentials for double phase competition during early stage precipitation. Chin Sci Bull 56:2055. https://doi.org/10.1007/s11434-011-4407-1

Faginas Lago N, Albertí M, Lombardi A, Pirani F (2016) A force field for acetone: the transition from small clusters to liquid phase investigated by molecular dynamics simulations. Theor Chem Acc. https://doi.org/10.1007/s00214-016-1914-9

El Mekkaoui N, Idrissi S, Mtougui S et al (2019) Monte Carlo study of the manganite oxide perovskite YMnO3. Appl Phys A. https://doi.org/10.1007/s00339-019-2880-6

Turlo V, Rupert TJ (2020) Prediction of a wide variety of linear complexions in face centered cubic alloys. Acta Mater 185:129. https://doi.org/10.1016/j.actamat.2019.11.069

Turlo V, Rupert TJ (2019) Linear complexions: metastable phase formation and coexistence at dislocations. Phys Rev Lett 122:126102. https://doi.org/10.1103/PhysRevLett.122.126102

Dontsova E, Rottler J, Sinclair CW (2015) Solute segregation kinetics and dislocation depinning in a binary alloy. Phys Rev B. https://doi.org/10.1103/PhysRevB.91.224103

Dontsova E, Rottler J, Sinclair CW (2014) Solute-defect interactions in Al–Mg alloys from diffusive variational Gaussian calculations. Phys Rev B. https://doi.org/10.1103/PhysRevB.90.174102

Li J, Sarkar S, Cox WT, Lenosky TJ, Bitzek E, Wang Y (2011) Diffusive molecular dynamics and its application to nanoindentation and sintering. Phys Rev B. https://doi.org/10.1103/PhysRevB.84.054103

Greenwood M, Provatas N, Rottler J (2010) Free energy functionals for efficient phase field crystal modeling of structural phase transformations. Phys Rev Lett 105:045702. https://doi.org/10.1103/PhysRevLett.105.045702

Greenwood M, Ofori-Opoku N, Rottler J, Provatas N (2011) Modeling structural transformations in binary alloys with phase field crystals. Phys Rev B. https://doi.org/10.1103/PhysRevB.84.064104

Elder KR, Provatas N, Berry J, Stefanovic P, Grant M (2007) Phase-field crystal modeling and classical density functional theory of freezing. Phys Rev B 75:794. https://doi.org/10.1103/PhysRevB.75.064107

Huang ZF, Elder KR, Provatas N (2010) Phase-field-crystal dynamics for binary systems: derivation from dynamical density functional theory amplitude equation formalism and applications to alloy heterostructures. Phys Rev E Stat Nonlinear Soft Matter Phys 82:021605. https://doi.org/10.1103/PhysRevE.82.021605

Provatas N, Elder K (2010) Phase-Field methods in materials science and engineering. Wiley

Greenwood M, Rottler J, Provatas N (2011) Phase-field-crystal methodology for modeling of structural transformations. Phys Rev E Stat Nonlinear Soft Matter Phys 83:031601. https://doi.org/10.1103/PhysRevE.83.031601

Fallah V, Ofori-Opoku N, Stolle J, Provatas N, Esmaeili S (2013) Simulation of early-stage clustering in ternary metal alloys using the phase-field crystal method. Acta Mater 61:3653. https://doi.org/10.1016/j.actamat.2013.02.053

Gránásy L, Tegze G, Tóth GI, Pusztai T (2011) Phase-field crystal modelling of crystal nucleation, heteroepitaxy and patterning. Philos Mag 91:123. https://doi.org/10.1080/14786435.2010.487476

Fallah V, Korinek A, Ofori-Opoku N, Provatas N, Esmaeili S (2013) Atomistic investigation of clustering phenomenon in the Al–Cu system: three-dimensional phase-field crystal simulation and HRTEM/HRSTEM characterization. Acta Mater 61:6372. https://doi.org/10.1016/j.actamat.2013.07.015

Hu Y, Chen YQ, Li L, Hu HD, Zhu ZA (2016) Microstructure and properties of Al/Cu bimetal in liquid–solid compound casting process. Trans Nonferr Met Soc China 26:1555. https://doi.org/10.1016/s1003-6326(16)64261-9

Rosalie JM, Bourgeois L, Muddle BC (2012) Precipitation of the phase in Al–Cu–Ag alloys. Light Metals. Springer, pp 307–312

Brown JE, Smith GDW (1991) Atom probe studies of spinodal processes in duplex stainless steels and single and dual phase Fe–Cr–Ni alloys. Surf Sci 1(3):285–291. https://doi.org/10.1016/0039-6028(91)90428-U

Danoix F, Auger P, Bostel A, Blavette D (1991) Atom probe characterization of isotropic spinodal decompositions: spatial convolutions and related bias. Surf Sci 246:A173. https://doi.org/10.1016/0039-6028(91)90424-Q

Müller M, Smith GDW, Gault B, Grovenor CRM (2012) Phase separation in thick InGaN layers–a quantitative, nanoscale study by pulsed laser atom probe tomography. Acta Mater 60:4277. https://doi.org/10.1016/j.actamat.2012.04.030

Knutsson A, Schramm IC, Asp Gronhagen K, Mucklich F, Oden M (2013) Surface directed spinodal decomposition at TiAlN/TiN interfaces. J Appl Phys 113:114305. https://doi.org/10.1063/1.4795155

Cantwell PR, Tang M, Dillon SJ, Luo J, Rohrer GS, Harmer MP (2014) Grain boundary complexions. Acta Mater 62:1. https://doi.org/10.1016/j.actamat.2013.07.037

Meiners T, Frolov T, Rudd RE, Dehm G, Liebscher CH (2020) Observations of grain-boundary phase transformations in an elemental metal. Nature 579:375. https://doi.org/10.1038/s41586-020-2082-6

Sahu S, Patel SK, Shekhar S (2020) The effect of grain boundary structure on chromium carbide precipitation in Alloy 600. Mater Chem Phys. https://doi.org/10.1016/j.matchemphys.2020.124145

Bjorge R, Marioara CD, Andersen SJ, Holmestad R (2010) Germanium network connecting precipitates in an Mg–rich Al–Mg–Ge alloy. J Electron Microsc. https://doi.org/10.1093/jmicro/dfq040

Kishida K, Yokobayashi H, Inui H (2017) A formation criterion for Order-Disorder (OD) phases of the long-period stacking order (LPSO)-type in Mg–Al–RE (rare earth) ternary systems. Sci Rep. https://doi.org/10.1038/s41598-017-12506-0

Jin S, Ngai T, Li L, Jia S, Zhai T, Ke D (2018) Aging response and precipitation behavior after 5% pre-deformation of an Al–Mg–Si–Cu alloy. Materials. https://doi.org/10.3390/ma11081422

Maeda T, Kaneko K, Namba T et al (2018) Structural and compositional study of precipitates in under-aged Cu-added Al–Mg–Si alloy. Sci Rep. https://doi.org/10.1038/s41598-018-35134-8

Acknowledgements

This work was supported by grants from the National Natural Science Foundation of China (Grant Nos. 51531009, 51801237), and the fund of the State Key Laboratory of Solidification Processing in NWPU (SKLSP201827).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they do not have any conflict of interest.

Additional information

Handling Editor: Avinash Dongare.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shuai, X., Wang, Z.J., Mao, H. et al. Atomic-scale study of compositional and structural evolution of early-stage grain boundary precipitation in Al–Cu alloys through phase-field crystal simulation. J Mater Sci 56, 12700–12715 (2021). https://doi.org/10.1007/s10853-021-06064-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06064-0