Abstract

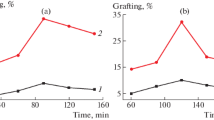

The graft copolymerization of lignocellulosic fibers with glycidyl methacrylate (GMA) using a Fe2+–thiourea dioxide–H2O2 redox system (Fe2+–TD–H2O2) was studied to overcome the problems of poor compatibility and low surface strength when cellulosic fibers are composited with synthetic polymers. The results show that cellulose–poly(GMA) (CPGMA) was successfully synthesized from GMA and bleached Eucalyptus cellulosic fibers by Fe2+–TD–H2O2 in a mild aqueous solution. CPGMA had high graft rate (244%), high content of epoxy group, and high stability in water. X-ray diffraction patterns and 13C cross-polarization magic angle spinning nuclear magnetic resonance spectra analyses showed that graft copolymerization did not change the crystalline structure of the CPGMA fiber backbone cellulose, but the crystallinity of the CPGMA fiber decreased with an increase in amorphous PGMA grafting. Scanning electron microscopy confirmed that the grafting reaction occurred both inside and outside the fiber. The specific surface area and pore diameter of the grafted fibers were significantly affected by the grafting. The hydrophobicity of the fibers was significantly enhanced by graft copolymerization. PGMA grafting can enhance the compatibility between the modified fiber and synthetic polymer matrix, improving the processing runnability and product properties of composite materials. A high intensity focused ultrasound method was used to analyze the fiber surface strength. It was confirmed that graft copolymerization significantly improved the surface strength of the grafted fibers. Graft copolymerization can significantly improve the dimensional stability of cellulosic fibers.

Graphic abstract

Similar content being viewed by others

References

Debashish R, Mona S, Guthrie JT, Sébastien P (2009) Cellulose modification by polymer grafting: a review. Chem Soc Rev 38(7):2046–2064. https://doi.org/10.1039/C8CS90134A

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: a review. Nanoscale 4(11):3274–3294. https://doi.org/10.1039/c2nr30260h

Mohit H, Selvan VAM (2018) A comprehensive review on surface modification, structure interface and bonding mechanism of plant cellulose fiber reinforced polymer based composites. Compos Interface 25(10):1–39. https://doi.org/10.1080/09276440.2018.1444832

Bhattacharya A, Misra BN (2004) Grafting: a versatile means to modify polymers - techniques, factors and applications. Prog Polym Sci 29(8):767–814. https://doi.org/10.1016/j.progpolymsci.2004.05.002

Kalia S, Sabaa MW (2013) Polysaccharide based graft copolymers. Springer, Berlin. https://doi.org/10.1007/978-3-642-36566-9

Xu PW, Zhao XY, Ma PM, Chen MQ, Dong WF, Hoch M, Lemstra PJ (2018) Design of nano-starch-reinforced ethyl-co-vinyl acetate elastomers by simultaneously constructing interfacial bonding and novel reversible matrix crosslinking. Chem Eng J 346:497–505. https://doi.org/10.1016/j.cej.2018.03.189

Zheng T, Zhang Z, Shukla S, Agnihotri S, Clemons CM, Pilla S (2019) PHBV-graft-GMA via reactive extrusion and its use in PHBV/nanocellulose crystal composites. Carbohyd Polym 205:27–34. https://doi.org/10.1016/j.carbpol.2018.10.014

Nguyen TC, Ruksakulpiwat C, Rugmai S, Soontaranon S, Ruksakulpiwat Y (2017) Crystallization behavior studied by synchrotron small-angle X-ray scattering of poly (lactic acid)/cellulose nanofibers composites. Compos Sci Technol 143:106–115. https://doi.org/10.1016/j.compscitech.2017.02.032

Capriotti AL, Cavaliere C, Ferraris F, Gianotti V, Laus M, Piovesana S, Sparnacci K, Chiozzi RZ, Laganà A (2017) New Ti-IMAC magnetic polymeric nanoparticles for phosphopeptide enrichment from complex real samples. Talanta 178:274–281. https://doi.org/10.1016/j.talanta.2017.09.010

Chu Z, Zhang L, Zhang W (2018) Preparation and evaluation of maltose modified polymer-silica composite based on cross-linked poly glycidyl methacrylate as high performance liquid chromatography stationary phase. Anal Chim Acta 1036:179–186. https://doi.org/10.1016/j.aca.2018.06.027

Sharma RK, Kumar R, Singh AP (2019) Metal ions and organic dyes sorption applications of cellulose grafted with binary vinyl monomers. Sep Purif Technol 209:684–697. https://doi.org/10.1016/j.seppur.2018.09.011

Sun LJ, Qian XR, Ding CY, An XH (2018) Integration of graft copolymerization and ring-opening reaction: a mild and effective preparation strategy for "clickable" cellulose fibers. Carbohyd Polym 198:41–50. https://doi.org/10.1016/j.carbpol.2018.06.054

Wei L, Mcdonald AG (2016) A review on grafting of biofibers for biocomposites. Materials 9(4):303. https://doi.org/10.3390/ma9040303

Missoum K, Belgacem MN, Bras J (2013) Nanofibrillated cellulose surface modification: a review. Materials 6(5):1745–1766. https://doi.org/10.3390/ma6051745

Spinella S, Samuel C, Raquez JM, Mccallum SA, Gross R, Dubois P (2016) Green and efficient synthesis of dispersible cellulose nanocrystals in biobased polyesters for engineering applications. ACS Sustain Chem Eng 4(5):2517–2527. https://doi.org/10.1021/acssuschemeng.5b01611

Ibrahim NA, Wan MZWY, Abu-Ilaiwi FA, Rahman MZA, Ahmad MB, Dahlan KZM (2010) Graft copolymerization of methyl methacrylate onto oil palm empty fruit bunch fiber using H2O2/Fe2+ as an initiator. J Appl Polym Sci 89(8):2233–2238. https://doi.org/10.1002/app.12467

Littunen K, Hippi U, Johansson L, Österberg M, Tammelin T, Laine J, Seppälä J (2011) Free radical graft copolymerization of nanofibrillated cellulose with acrylic monomers. Carbohyd Polym 84(3):1039–1047. https://doi.org/10.1016/j.carbpol.2010.12.064

Guo L, Li D, Lennholm H, Zhai H, Ek M (2019) Structural and functional modification of cellulose nanofibrils using graft copolymerization with glycidyl methacrylate by Fe2+–thiourea dioxide–H2O2 redox system. Cellulose 26:4853–4864. https://doi.org/10.1007/s10570-019-02411-2

El-Alfy E, Waly A, Hebeish A (1985) Graft copolymerization of perfluoroheptyl methacrylate/glycidyl methacrylate mixtures with cotton fabric using Fe2+-thioureadioxide-H2O2 redox system. Die Angewandte Makromoleculate Chemie 130(1):137–146. https://doi.org/10.1002/apmc.1985.051300111

Misra BN, Dogra R, Kaur I, Jassal JK (1979) Grafting onto cellulose IV Effect of complexing agents on fenton's reagent (Fe2+/H2O2)-initiated grafting of poly(vinyl acetate). J Polym Sci Polym Chem Edit 17(6):1861–1863. https://doi.org/10.1002/pol.1979.170170631

Abou-Zeid NY, Waly A, El-Alfy EA, Hebeish A (1982) Fe2+–thioureadioxide–H2O2-induced polymerization of glycidyl methacrylate and its mixtures with acrylamide, acrylonitrile, butylmethacrylate, or styrene with cotton fabric. J Appl Polym Sci 27(6):2105–2117. https://doi.org/10.1002/app.1982.070270622

Huang J, Zhai HM (2008) Graft copolymerization of glycidyl methacrylate with eucalyptus pulp induced by Fe2+–H2O2–thioureadioxide Redox System. Chem Ind For Prod 28(2):58–62

Yang G, Zhai HM (2012) Synthesis and properties of glycidyl methacrylate grafted Eucalyptus fiber. Cell Chem Technol 46(33–4):243–248

Zhou Y, Fan M, Chen L (2016) Interface and bonding mechanisms of plant fibre composites: an overview. Compos Part B-Eng 101:31–45. https://doi.org/10.1016/j.compositesb.2016.06.055

Rosli NA, Ahmad I, Anuar FH, Abdullah I (2019) Application of polymethylmethacrylate-grafted cellulose as reinforcement for compatibilised polylactic acid/natural rubber blends. Carbohyd Polym 213:50–58. https://doi.org/10.1016/j.carbpol.2019.02.074

Gil BM, Song SW, Lee JH, Jeon J, Lee KH, Wie JJ (2019) Introduction of primary chemical bonding in lignin-based PP composites for mechanical reinforcement via reactive extrusion. Compos Part B-Eng 165:510–515. https://doi.org/10.1016/j.compositesb.2019.02.014

Ramesh M (2019) Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: a review on preparation, properties and prospects. Prog Mater Sci 102:109–166. https://doi.org/10.1016/j.pmatsci.2018.12.004

Aouat T, Kaci M, Lopez-Cuesta JM, Devaux E, Mahlous M (2019) The effect of gamma-irradiation on morphology and properties of melt-spun poly (lactic acid)/cellulose fibers. Polym Degrad Stabil 160:14–23. https://doi.org/10.1016/j.polymdegradstab.2018.11.014

Sirvio JA, Visanko M, Ukkola J, Liimatainen H (2018) Effect of plasticizers on the mechanical and thermomechanical properties of cellulose-based biocomposite films. Ind Crop Prod 122:513–521. https://doi.org/10.1016/j.indcrop.2018.06.039

Wang S, Lu A, Zhang L (2016) Recent advances in regenerated cellulose materials. Prog Polym Sci 53:169–206. https://doi.org/10.1016/j.progpolymsci.2015.07.003

Zeiger BW, Suslick KS (2011) Sonofragmentation of molecular crystals. J Am Chem Soc 133(37):14530–14533. https://doi.org/10.1021/ja205867f

Ho BJ, Suslick KS (2010) Applications of ultrasound to the synthesis of nanostructured materials. Adv Mater 22(10):1039–1059. https://doi.org/10.1002/chin.201018217

Wang ZH, Wang ZH, Pan XC, Fu LY, Lathwal S, Olszewski M, Yan JJ, Enciso AE, Wang ZY, Xia HS, Matyjaszewski K (2018) Ultrasonication-induced aqueous atom transfer radical polymerization. ACS Macro Lett 7(3):275–280. https://doi.org/10.1021/acsmacrolett.8b00027

Zhao HP, Feng XQ, Gao H (2007) Ultrasonic technique for extracting nanofibers from nature materials. Appl Phys Lett 90(7):073112. https://doi.org/10.1063/1.2450666

Tischer PCSF, Sierakowski MR, Harry Westfahl J (2010) Nanostructural reorganization of bacterial cellulose by ultrasonic treatment. Biomacromol 11(5):1217–1224. https://doi.org/10.1021/bm901383a

Chen WS, Yu HP, Liu YX, Chen P, Zhang MX, Hai YF (2011) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohyd Polym 83(4):1804–1811. https://doi.org/10.1016/j.carbpol.2010.10.040

Tonoli GHD, Teixeira EM, Corrêa AC, Marconcini JM, Caixeta LA, Pereira-Da-Silva MA, Mattoso LHC (2012) Cellulose micro/nanofibres from Eucalyptus kraft pulp: preparation and properties. Carbohyd Polym 89(1):80–88. https://doi.org/10.1016/j.carbpol.2012.02.052

O'Connell DW, Birkinshaw C, O'Dwyer TF (2006) A chelating cellulose adsorbent for the removal of Cu(II) from aqueous solutions. J Appl Polym Sci 99(6):2888–2897. https://doi.org/10.1002/app.22568

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:10. https://doi.org/10.1186/1754-6834-3-10

Segal L, Creely JJ, Martin AE Jr, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Wang S, Lu S, Song Z, Zhao J, Feng Y (2012) Preparation of epoxy functionalized PP with unique structure and its post-ring open reaction. J Appl Polym Sci 124(6):4827–4837. https://doi.org/10.1002/app.35569

Alberti A, Bertini S, Gastaldi G, Iannaccone N, Macciantelli D, Torri G, Vismara E (2005) Electron beam irradiated textile cellulose fibres. ESR studies and derivatisation with glycidyl methacrylate (GMA). Eur Polym J 41(8):1787–1797. https://doi.org/10.1016/j.europolymj.2005.02.016

Margutti S, Vicini S, Proietti N, Capitani D, Conio G, Pedemonte E, Segre AL (2002) Physical–chemical characterisation of acrylic polymers grafted on cellulose. Polymer 43(23):6183–6194. https://doi.org/10.1016/S0032-3861(02)00533-5

Atalla RH, Vanderhart DL (1999) The role of solid state 13C NMR spectroscopy in studies of the nature of native celluloses. Solid State Nucl Mag 15(1):1–19. https://doi.org/10.1016/S0926-2040(99)00042-9

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21(2):885–896. https://doi.org/10.1007/s10570-013-0030-4

Wang S, Cheng Q (2010) A novel process to isolate fibrils from cellulose fibers by high-intensity ultrasonication, part 1: process optimization. J Appl Polym Sci 113(2):1270–1275. https://doi.org/10.1002/app.30072

Chen Z, Li J, He B, Zhao L (2017) Fabrication of hydrophobic biocomposite by combining cellulosic fibers with polyhydroxyalkanoate. Cellulose 24(5):2265–2274. https://doi.org/10.1007/s10570-017-1235-8

Kellersztein I, Dotan A (2016) Chemical surface modification of wheat straw fibers for polypropylene reinforcement. Polym Composite 37(7):2133–2141. https://doi.org/10.1002/pc.23392

Wei L, Stark NM, McDonald AG (2015) Interfacial improvements in biocomposites based on poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) bioplastics reinforced and grafted with α-cellulose fibers. Green Chem 17(10):4800–4814. https://doi.org/10.1039/c5gc01568e

Acknowledgements

The authors are grateful for the support of the National Natural Science Foundation of China (Grant Nos. 31070524 and 31600474) and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, L., Meng, A., Wang, L. et al. Improving the compatibility, surface strength, and dimensional stability of cellulosic fibers using glycidyl methacrylate grafting. J Mater Sci 55, 12906–12920 (2020). https://doi.org/10.1007/s10853-020-04932-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04932-9